Low-deformation gear steel and manufacturing method thereof

A gear steel, low deformation technology, applied in the field of alloy steel, can solve the problems of not considering the influence of heat treatment deformation of gear steel, unfavorable grain size refinement, low rolling temperature, etc., to improve the band structure and grain size , uniform structure and composition of steel, and the effect of reducing heat treatment deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned low-deformation gear steel adopts a two-step technological process: the first step: primary smelting in an electric furnace→ladle refining+vacuum degassing→continuous casting; specifically,

[0033] The first step, primary smelting in electric furnace → ladle refining + vacuum degassing → continuous casting

[0034] Primary smelting of molten steel in an electric arc furnace of 60-150 tons; refining of ladles of corresponding tonnage; continuous casting; production of 140×140mm 2 ~320×425mm 2 Qualified continuous casting slabs with section dimensions:

[0035] 1. Initial smelting of electric furnace: low P and S scrap steel, cut ends and high-quality pig iron are used as the furnace material. Ferrochrome, low phosphorus ferromanganese, ferromolybdenum, etc. are required for the alloy. Reductant: ferrosilicon powder, carbon powder, aluminum powder; oxidation period : Frequent slag removal of P, slag tapping conditions: T=1...

Embodiment

[0046] The chemical composition of the steel of the embodiment of the present invention is shown in Table 1.

[0047] The chemical composition of table 1 embodiment

[0048] C

Si

mn

P

S

Cr

Mo

Al

Cu

N

Example 1

0.18

0.24

0.80

0.010

0.015

1.22

0.21

0.030

0.15

0.0111

Example 2

0.10

0.22

0.89

0.011

0.020

1.23

0.35

0.035

0.09

0.0165

Example 3

0.22

0.21

0.70

0.010

0.024

1.01

0.22

0.038

0.09

0.0180

Example 4

0.25

0.18

0.68

0.009

0.033

0.95

0.18

0.042

0.10

0.0197

Example 5

0.18

0.23

0.75

0.008

0.028

1.15

0.23

0.022

0.09

0.0106

Example 6

0.27

0.15

0.65

0.018

0.035 ...

PUM

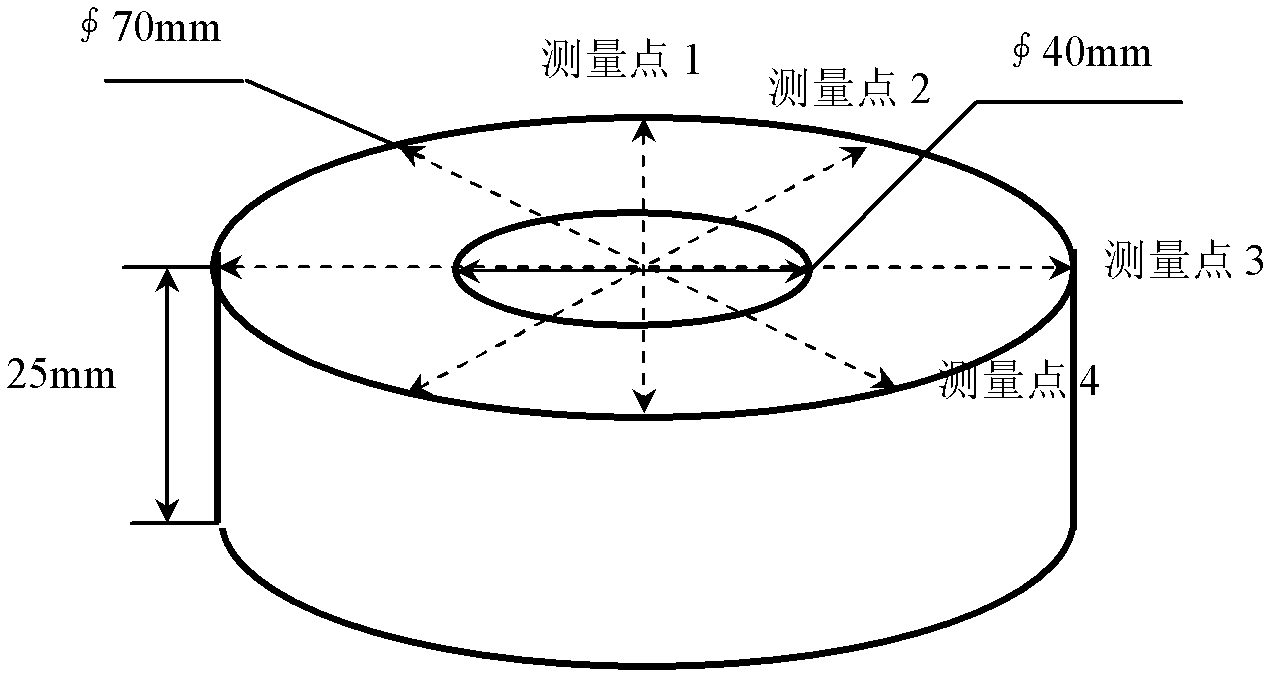

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com