Blumea oil microcapsule textile composite finishing agent and use thereof

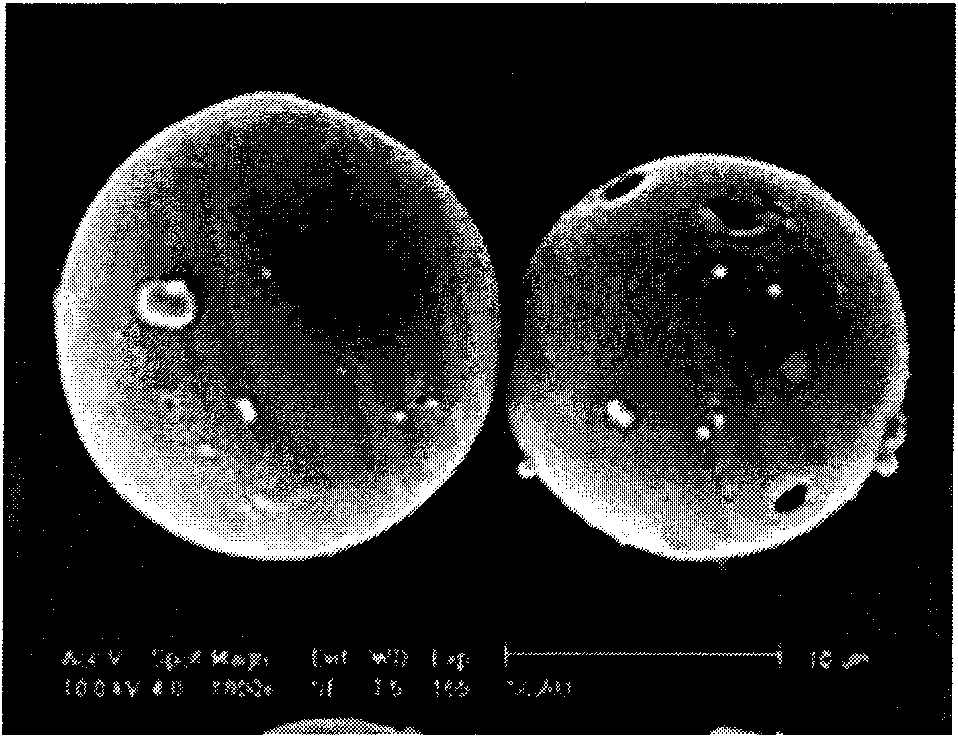

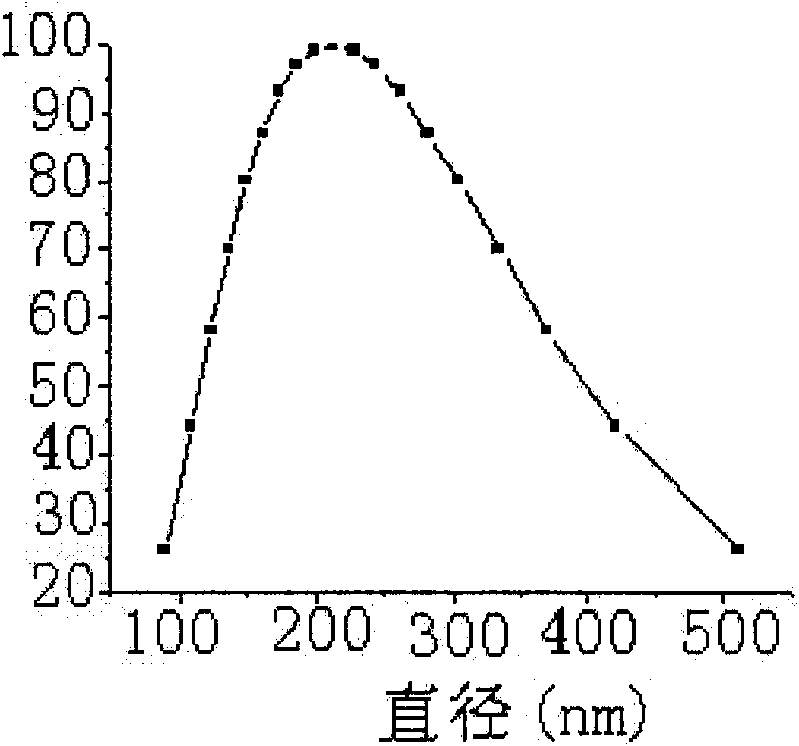

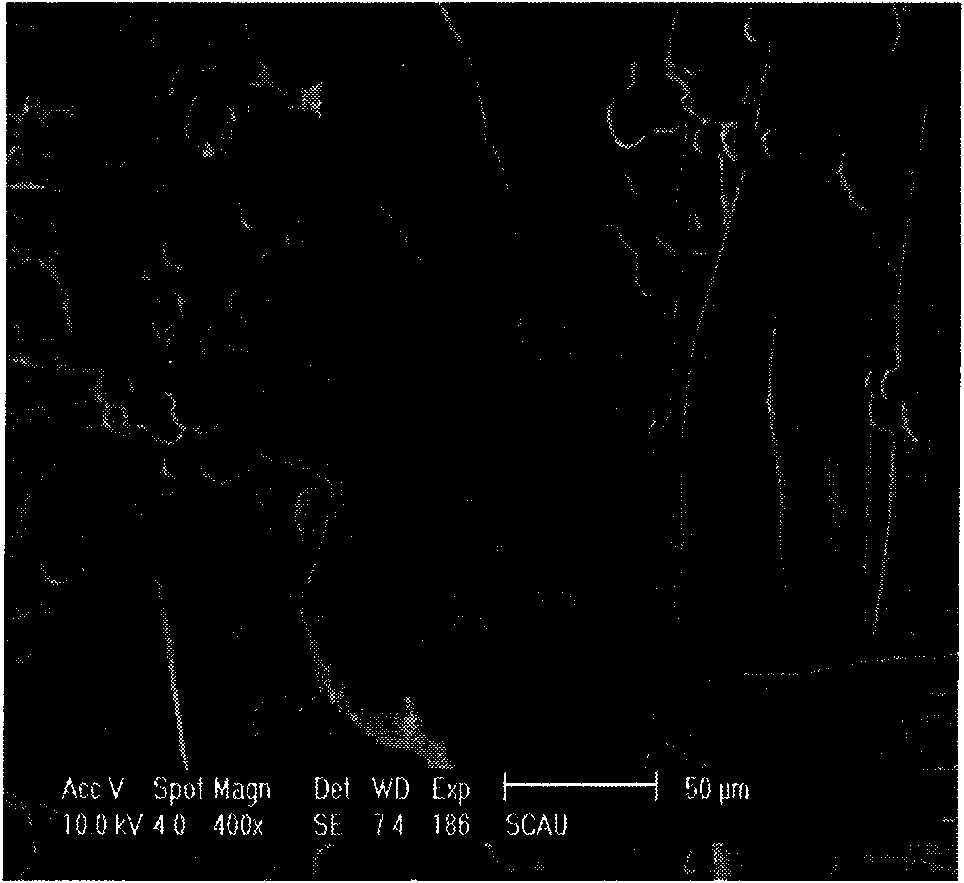

A technology of mugwort oil and microcapsules, which is applied in the field of fabric composite finishing agents of mugwort oil microcapsules, can solve the problem of formaldehyde that has not been properly solved without providing antibacterial, deodorant, insect repellent, fragrance, wrinkle-proof, and washable technical solutions. There are few types of natural health care textile products, etc., to achieve the effect of wide application range, regular shape and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1. Oxidative degradation of chitosan

[0059] Weigh a certain amount of chitosan and add it to a three-necked flask, heat it in a constant temperature water bath at 50°C, dissolve it with 2.5% acetic acid solution, stir it at 400r / min for 5 minutes, and then add an appropriate amount of 4% H 2 o 2 The solution was reacted for 4 hours. After the reaction, the pH value of the reaction system was adjusted to 7.0 with 10% NaOH solution, and the neutralized reaction solution was added dropwise into acetone twice the volume of the reaction solution under stirring conditions for precipitation. After standing overnight, suction filter and dry to obtain the degradation product for future use.

[0060] 2. Mugwort oil emulsification: Weigh 1.0g gelatin, 2.0g mugwort oil and 0.5g emulsifier Span-80 into a 500mL three-neck flask, add 100.0g deionized water and mix evenly, dissolve at 40°C, dissolve at 1500r / min speed for emulsification for 15min.

[0061] 3. Complex coacervatio...

Embodiment 2

[0087] 1. Oxidative degradation of chitosan

[0088] Weigh a certain amount of chitosan and add it to a three-necked flask, heat it in a constant temperature water bath at 50°C, dissolve it with 2.5% acetic acid solution, stir it at 400r / min for 5 minutes, and then add an appropriate amount of 4% H 2 o 2 The solution was reacted for 4 hours. After the reaction, the pH value of the reaction system was adjusted to 7.0 with 10% NaOH solution, and the neutralized reaction solution was added dropwise into acetone twice the volume of the reaction solution under stirring conditions for precipitation. After standing overnight, suction filter and dry to obtain the degradation product for future use.

[0089] 2. Artemisia oil emulsification: Weigh 10.0g of gum arabic, 4.0g of artemisia oil and 1.0g of emulsifier Tween-80 into a 500mL three-neck flask, add 100.0g of deionized water and mix well, dissolve at 40°C, dissolve with Emulsify at a speed of 2000r / min for 15min.

[0090] 3. C...

Embodiment 3

[0145] 1. Oxidative degradation of chitosan

[0146] Weigh a certain amount of chitosan and add it to a three-necked flask, heat it in a constant temperature water bath at 50°C, dissolve it with 2.5% acetic acid solution, stir it at 400r / min for 5 minutes, and then add an appropriate amount of 4% H 2 o 2 The solution was reacted for 4 hours. After the reaction, the pH value of the reaction system was adjusted to 7.0 with 10% NaOH solution, and the neutralized reaction solution was added dropwise into acetone twice the volume of the reaction solution under stirring conditions for precipitation. After standing overnight, suction filter and dry to obtain the degradation product for future use.

[0147] 2. Mugwort oil emulsification: Weigh 2.0g gelatin, 4.0g mugwort oil and 1.0g emulsifier OP-10 into a 500mL three-necked flask, add 100.0g deionized water and mix well, dissolve at 40°C, dissolve at 1500r / min speed for emulsification for 15 min.

[0148] 3. Complex coacervation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wrinkle recovery angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com