Magnetic separation-centrifuge separation technology of micro-fine particle dissemination magnet-hematite mixed ore

A centrifuge and mixed ore technology, applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problem of increasing the amount of flotation reagents and beneficiation costs, increasing the processing capacity of flotation operations, and the large consumption of flotation reagents. and other problems, to achieve the effect of reducing the link of dispensing, reducing the amount of ore feeding in the operation, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

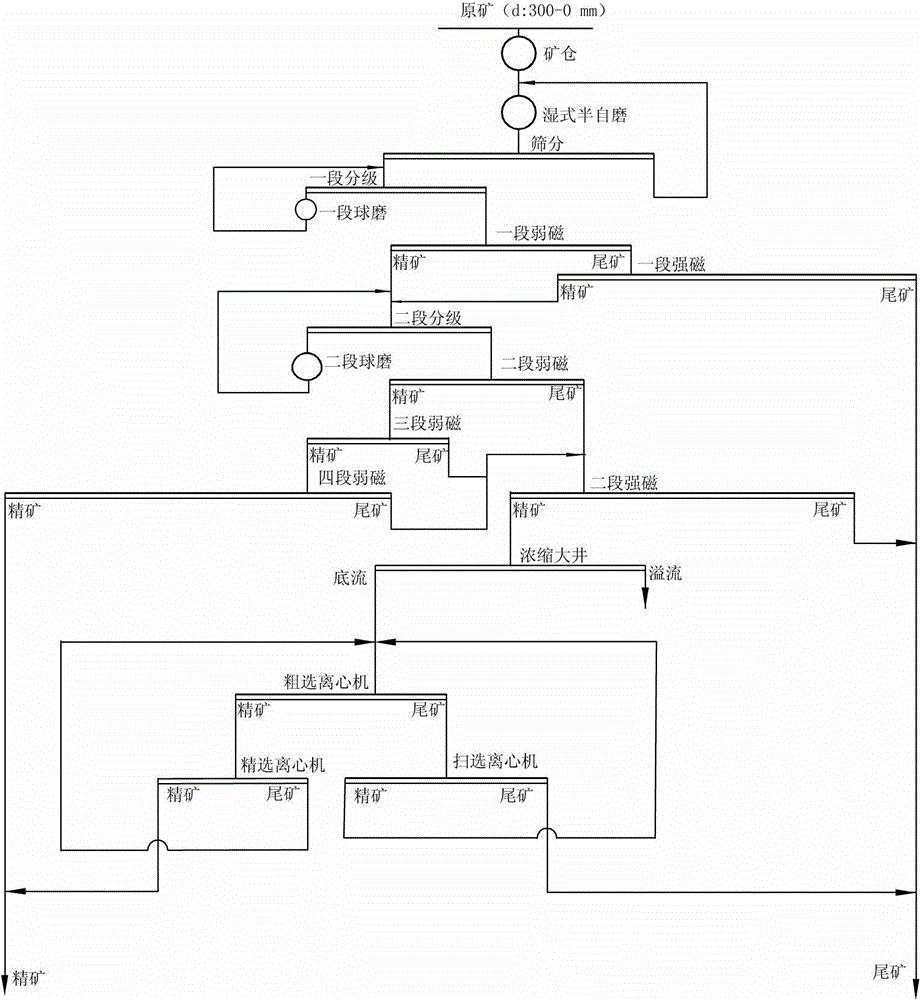

[0025] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] like figure 2 shown , the magnetic separation-centrifuge separation process of a kind of fine-grain embedded magnetic-red mixed ore of the present invention is characterized in that: adopt wet semi-self-grinding, stage grinding, stage weak magnetic-strong magnetic, strong magnetic

[0027] Fine-centrifuge sorting operation system, the specific steps are as follows:

[0028] a) Raw ore with a grade of 31% to 33%, a magnetic iron content of 40 to 60%, and a particle size of less than 300mm is fed into the wet semi-autogenous grinding-screening operation through the ore storage bin, and the -3mm product under the screen is fed into a closed circuit The grinding and grading system performs a stage of grinding and grading treatment, and the products on the screen return to the wet semi-autogenous grinding for regrinding;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com