Beneficiation method combining metal accumulation with authigenic carrier flotation

A combination and flotation technology, applied in the direction of solid separation, etc., can solve the problems of not being able to satisfy the tungsten fine mud selection process, the large difference in specific gravity between tungsten minerals and main vein ores, and the wide range of particle sizes, etc., to achieve The effect of simplifying the assembly line process, increasing the flotation rate, concentrate grade and recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

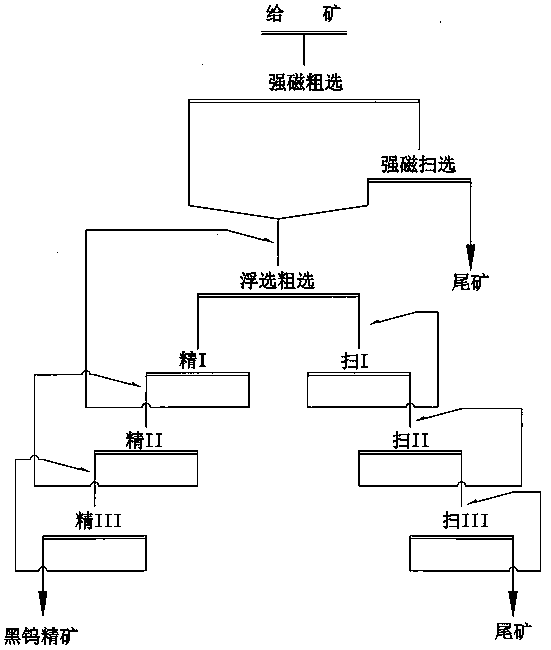

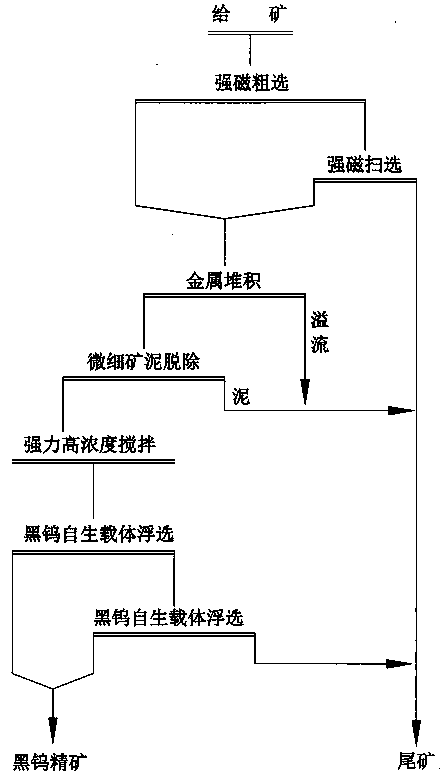

[0049] Taking a polymetallic ore dressing plant in Hunan as an example, the original design production capacity of the dressing plant is 2,000 tons of raw ore per day, and two sets of SLon-3000 vertical ring pulsating high-gradient strong magnetic separators are used for rough separation of black tungsten fine mud, and flotation ( Selected) process is a conventional flotation process of one coarse, three fine and three sweep. And after adopting the mineral processing method of the present invention, economic benefit can be significantly improved.

[0050] (1) Reduce investment in concentrator

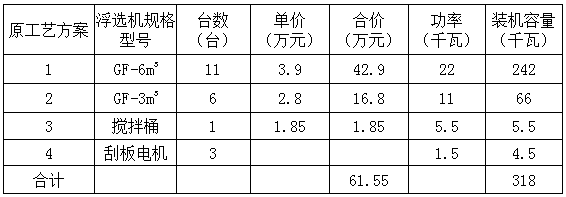

[0051] The original process flow flotation machine is configured as rough sweeping configuration GF-6m 3 Flotation machine, roughing 4 sets, sweeping Ⅰ 3 sets, sweeping Ⅱ 2 sets, sweeping Ⅲ 2 sets, selection configuration GF-3m 3 Flotation machine, select Ⅰ 3 sets, select Ⅱ 2 sets, select Ⅲ 1 set, share GF-6m 3 11 flotation machines, GF-3m 3 There are 6 flotation machines, and 1 mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com