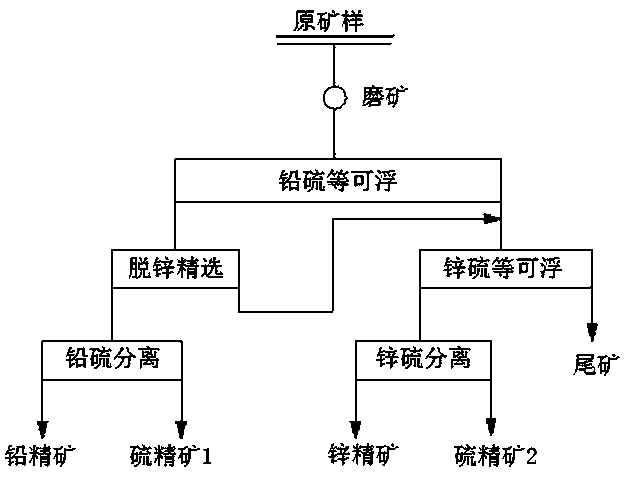

Flotation separation technology for high-sulfur and low-grade lead-zinc ore

A low-grade, lead-zinc ore technology, applied in flotation, solid separation, etc., can solve the problems of main metal loss and main metal mineral loss, and achieve the effect of low cost, strong adaptability and good technical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

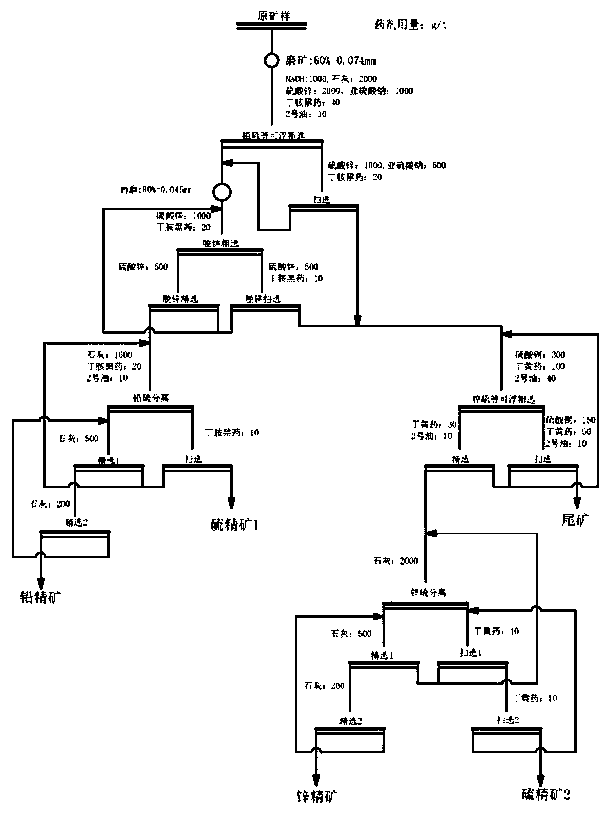

Embodiment 1

[0046] Raw ore is used to coarsely grind lead and sulfur, which can be floated-coarse concentrate and then grind lead and sulfur to separate, and tailings zinc and sulfur can be floated to separate zinc and sulfur. Amine black medicine, detailed process flow and pharmaceutical system see figure 2 , the results are shown in Table 2.

[0047] Table 2 Test results of implementation case 1

[0048]

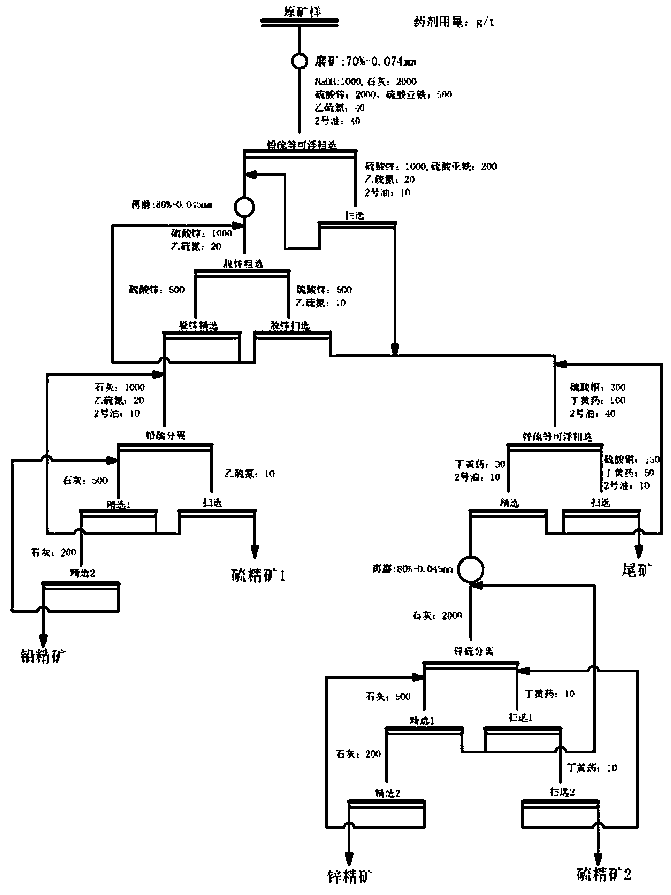

Embodiment 2

[0050] Raw ore is used to coarsely grind lead and sulfur, which can be floated-coarse concentrate and then grind to separate lead and sulfur. Ferrous iron, the collector is ethylsulfide nitrogen, detailed process flow and reagent system see image 3 , the results are shown in Table 3.

[0051] Table 3 Implementation Case 2 Test Results

[0052] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com