Apparatus and method for collecting and treating waste

a technology for collecting and treating waste materials, applied in the direction of liquid degasification, separation process, borehole/well accessories, etc., can solve the problems of contaminating ground water, material leaching into the ground, and plant life at or around the area where sludge is dumped, etc., to reduce the air pressure within the conduit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

I. Introduction and Definitions

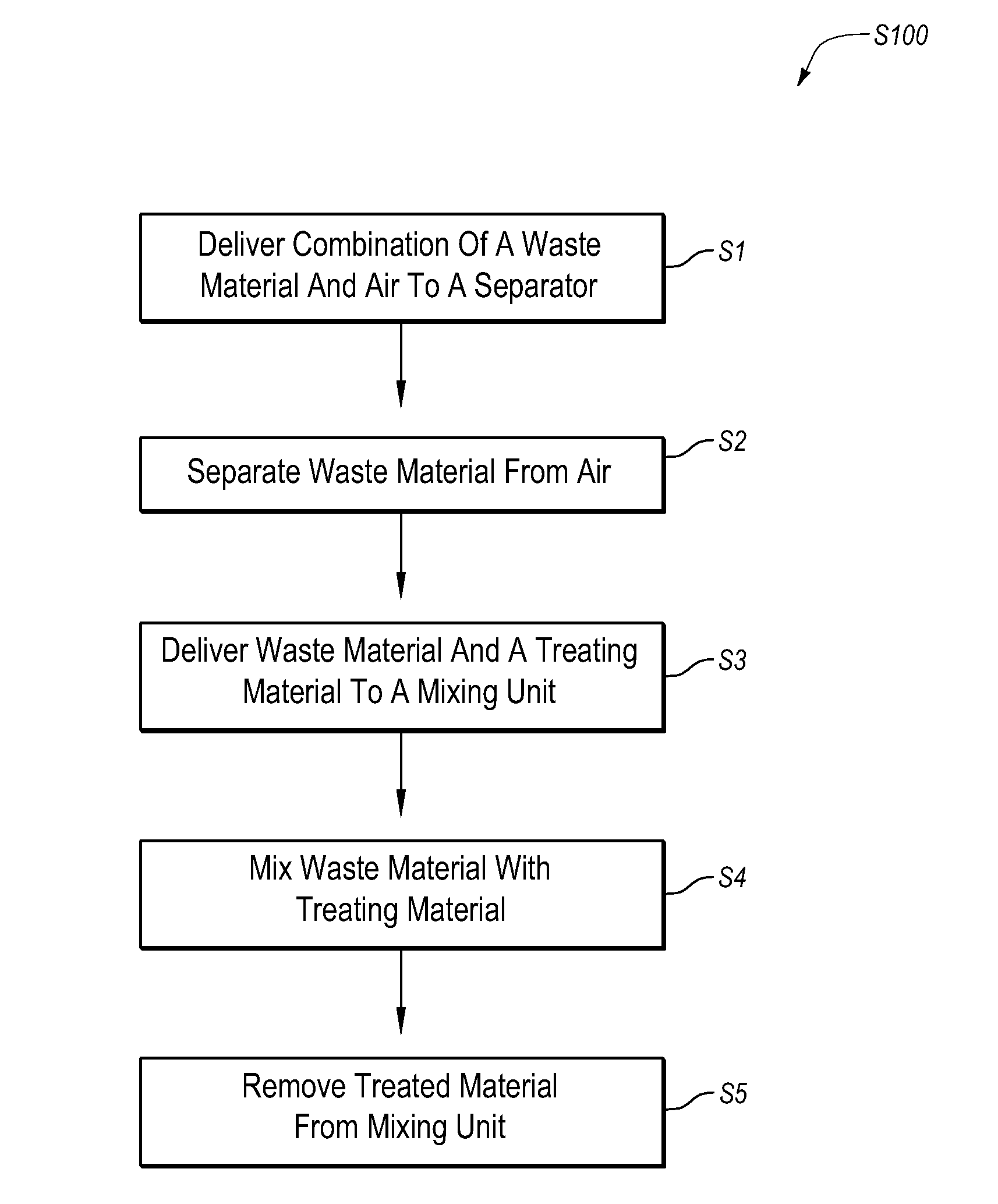

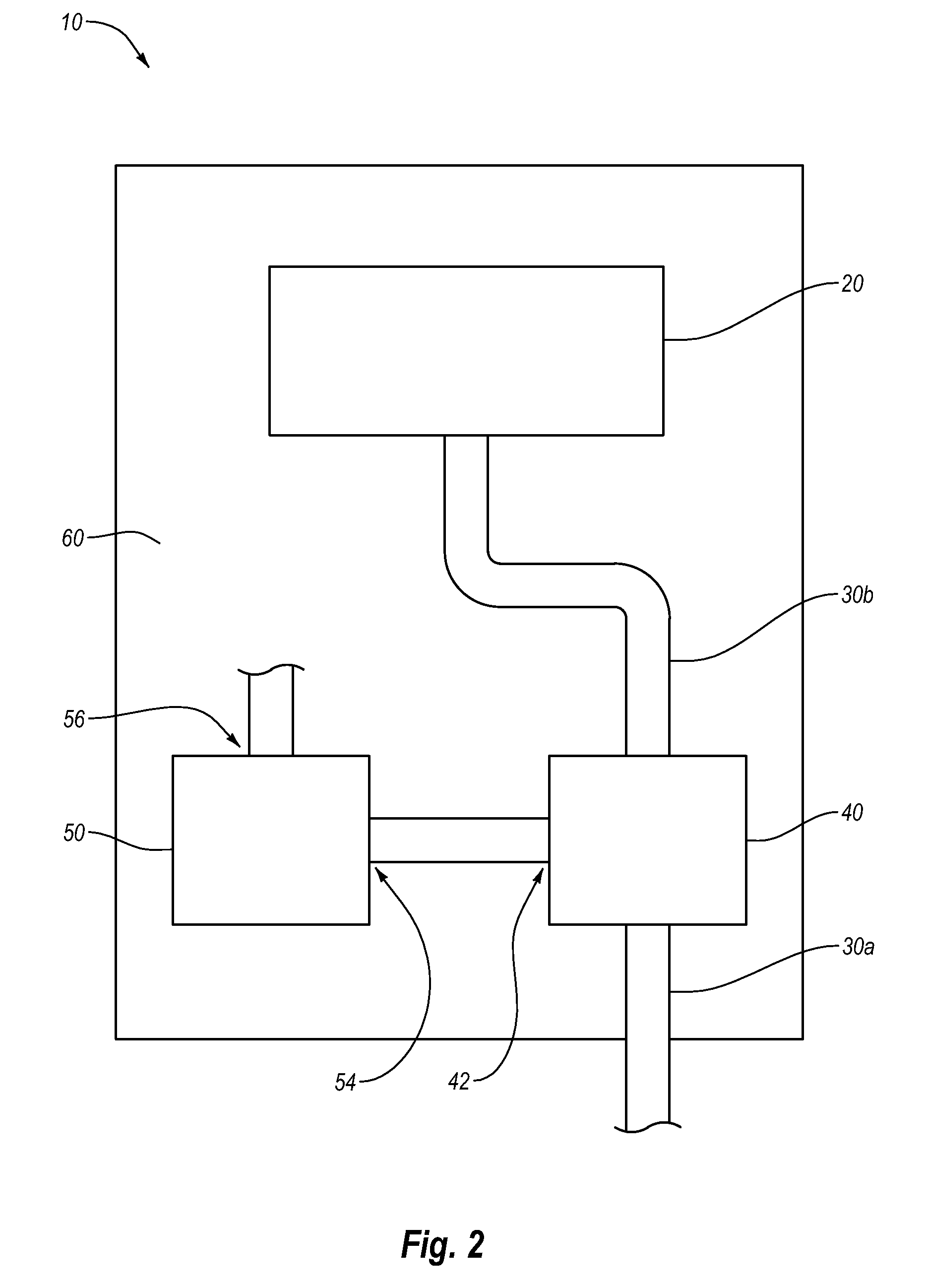

[0028]Implementations of the present invention solve one or more of the problems in the art with an apparatus for collecting and treating waste materials. In particular, one implementation of the present invention includes a mobile and integrated apparatus for continuously collecting and treating a waste material with a portable unit that can be stationed at a waste production site. The present invention also provides methods for collecting and treating waste material with a portable apparatus that continuously collects and treats a waste material.

[0029]Waste material, as that term is used herein, can include any material that requires some form of treatment before it can be disposed of at a landfill, used as a construction fill material, or otherwise discarded. A waste material can include a variety of materials in various forms. For example, a waste material can be wet or dry. A waste material may be a liquid, a solid, a slurry, or a gelatinous subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com