Micro-fluid pump with active control capability

An active control, microfluidic technology, applied in pumps with flexible working elements, pump control, components of pumping devices for elastic fluids, etc., can solve the difficulty of processing technology and integration, small pump flow, complex structure, etc problem, to achieve the effect of reducing hysteresis, good insulation performance and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

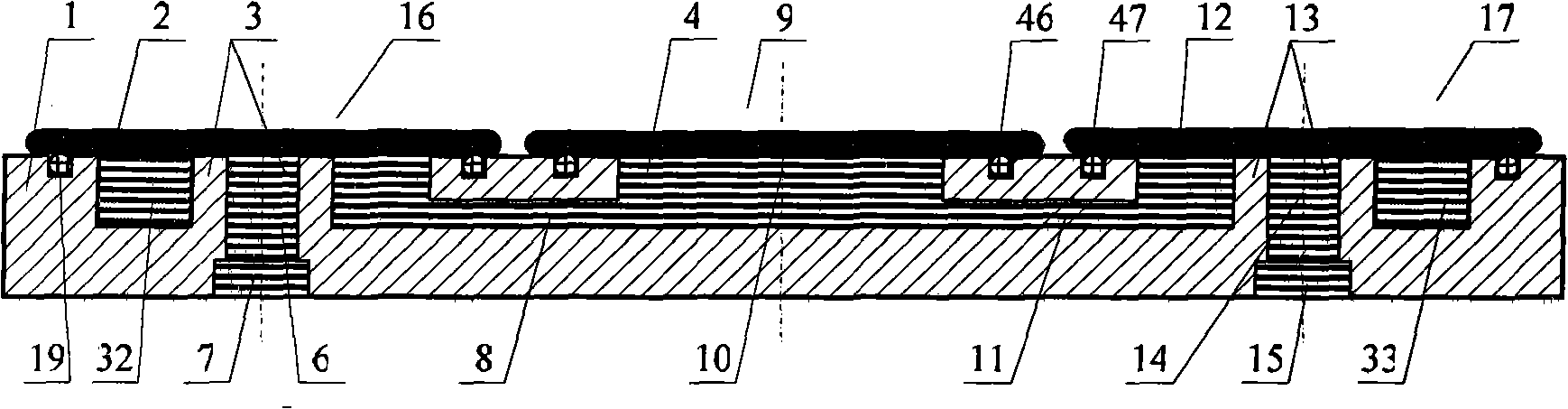

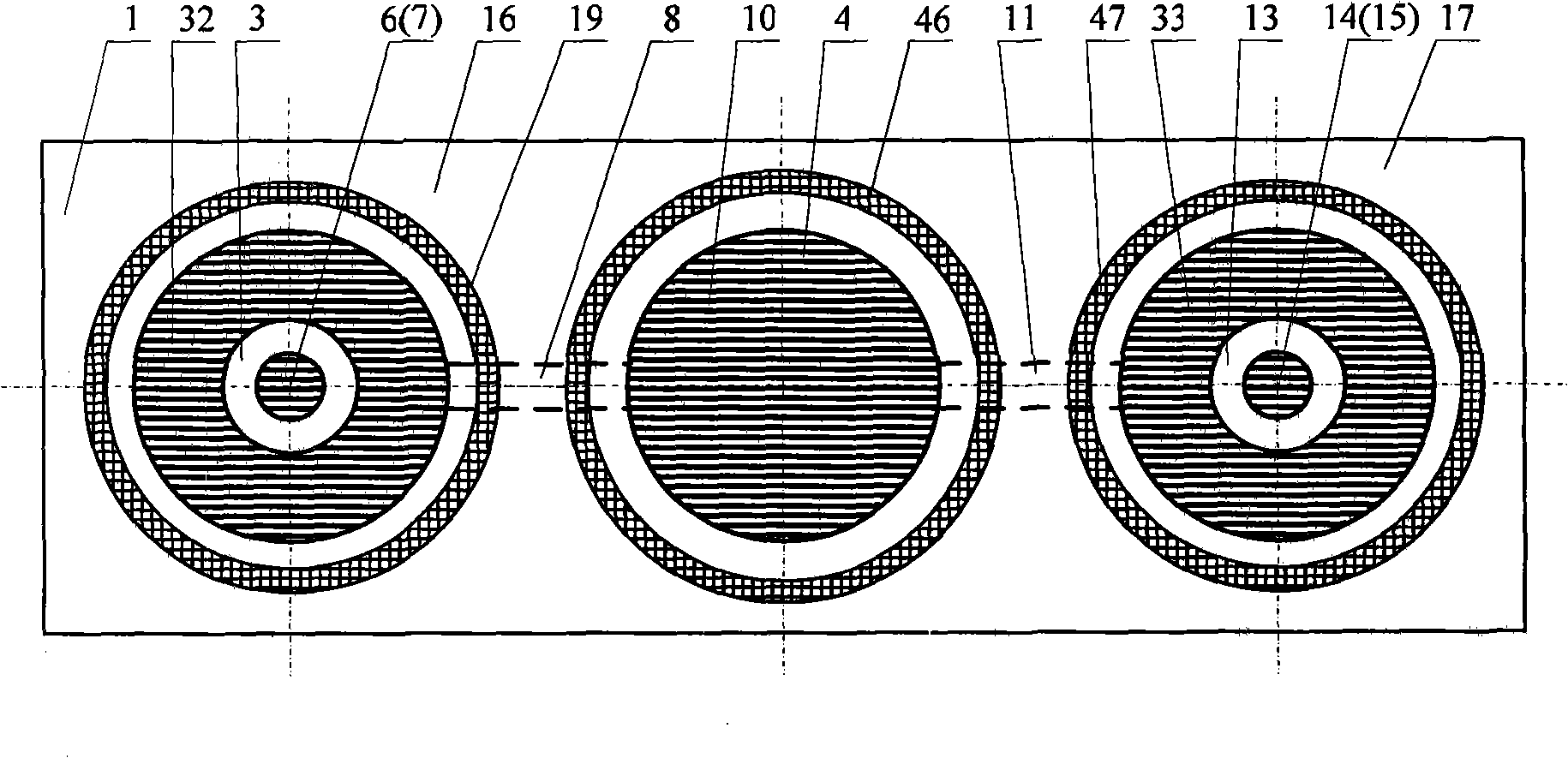

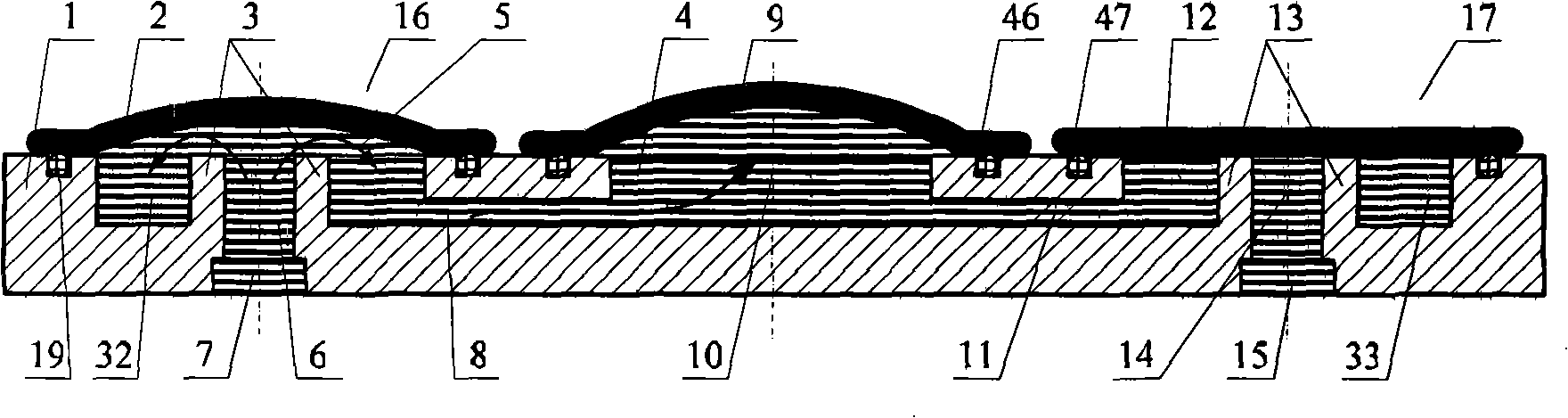

[0034] Referring to the accompanying drawings, the specific implementation of the microfluidic pump with active and precise control capability of the present invention will be described in detail below.

[0035] In the drawings: 1 is the pump body, 2, 9, 12, 39 are thin film actuators, 3 and 13 are toroidal bosses, 4 is fluid, 5 and 18 are microfluidic flow directions, 6 and 14 are microfluidic The cylindrical center hole of the valve, 44 is the liquid inlet channel (liquid outlet channel), 7 is the liquid inlet (liquid outlet), 8, 11, 34, 35 are flow passages, 10 and 42 are cylindrical pump chambers, 45 is a liquid outlet channel (liquid inlet channel), 15 is a liquid outlet (liquid inlet port), 16 is a liquid inlet valve (liquid outlet valve), 17 is a liquid outlet valve (liquid inlet valve), 32 and 33 are rings Cylindrical valve cavity, 23, 25, 27, 41 are elastic diaphragms, 22, 24, 26, 40 are piezoelectric ceramic discs / electrostrictive ceramic discs, 19, 46, 47, 48 are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com