Supercritical water oxidation treatment system and supercritical water oxidation treatment system process for high-concentration dyeing sludge

A supercritical water oxidation, printing and dyeing sludge technology, applied in the direction of oxidation treatment of sludge, etc., can solve the problems of SCWO system clogging and solid deposition, and achieve the effect of improving stability and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

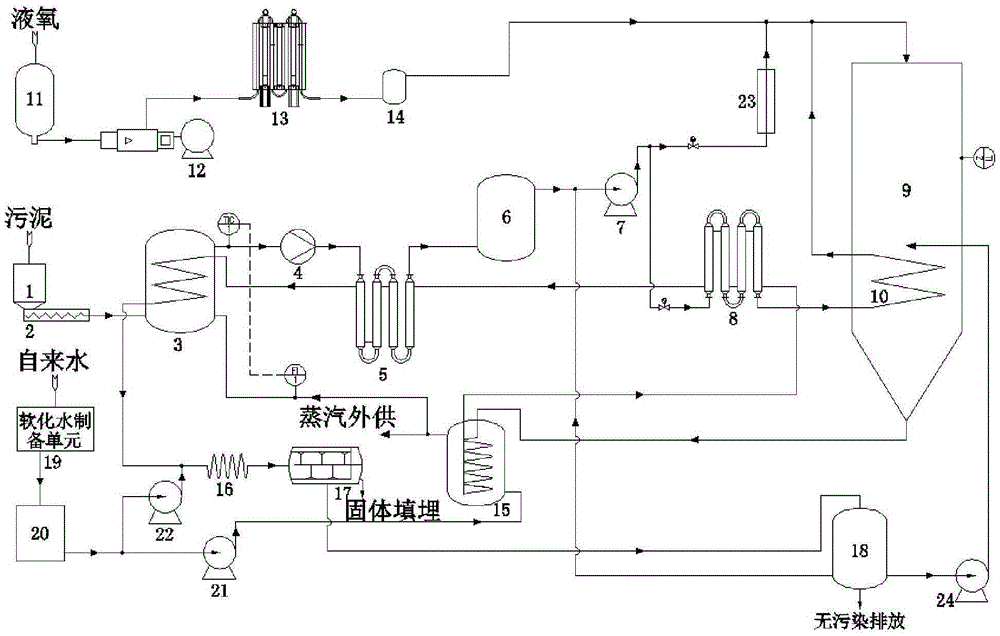

[0030] see figure 1 As shown, a kind of high-concentration printing and dyeing sludge supercritical water oxidation treatment system of the present invention includes a main body system and a softened water system:

[0031]1) Main system: The lower part of the sludge storage tank 1 is connected to the inlet of the screw pump 2, the outlet of the screw pump 2 is connected to the lower inlet of the shell side of the first heat exchanger 3, the upper outlet of the shell side of the first heat exchanger 3 is connected to the inlet of the grinding pump 4, and the grinding The outlet of the pump 4 is connected to the inlet of the inner tube of the second heat exchanger 5, the outlet of the inner tube of the second heat exchanger 5 is connected to the lower inlet of the hydrothermal reactor 6, and the upper outlet of the hydrothermal reactor 6 is connected to the inlet of the high-pressure diaphragm pump 7; the high-pressure diaphragm pump 7. The outlet is connected to the inlet of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com