Pipe heat exchanger, dual deflection flanged bend, adapter, system and method for transferring heat

A heat transfer, double-circuit technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problems of limiting the inner layer space of heat transfer, thermal expansion of heat transfer tubes, shortening service life, etc., to achieve The effect of maximizing heat transfer area, reducing cleaning frequency, and simplifying stacking or bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

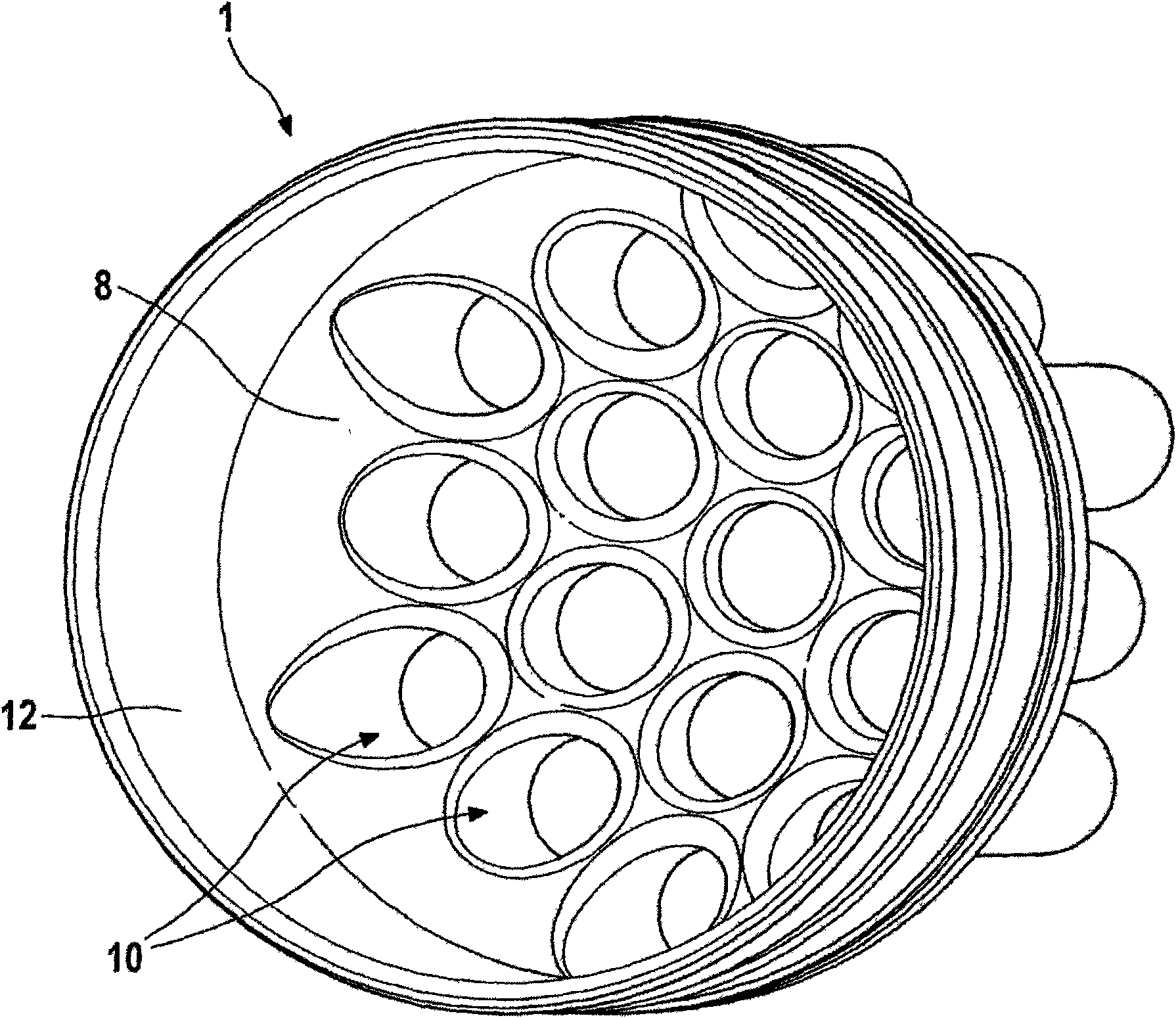

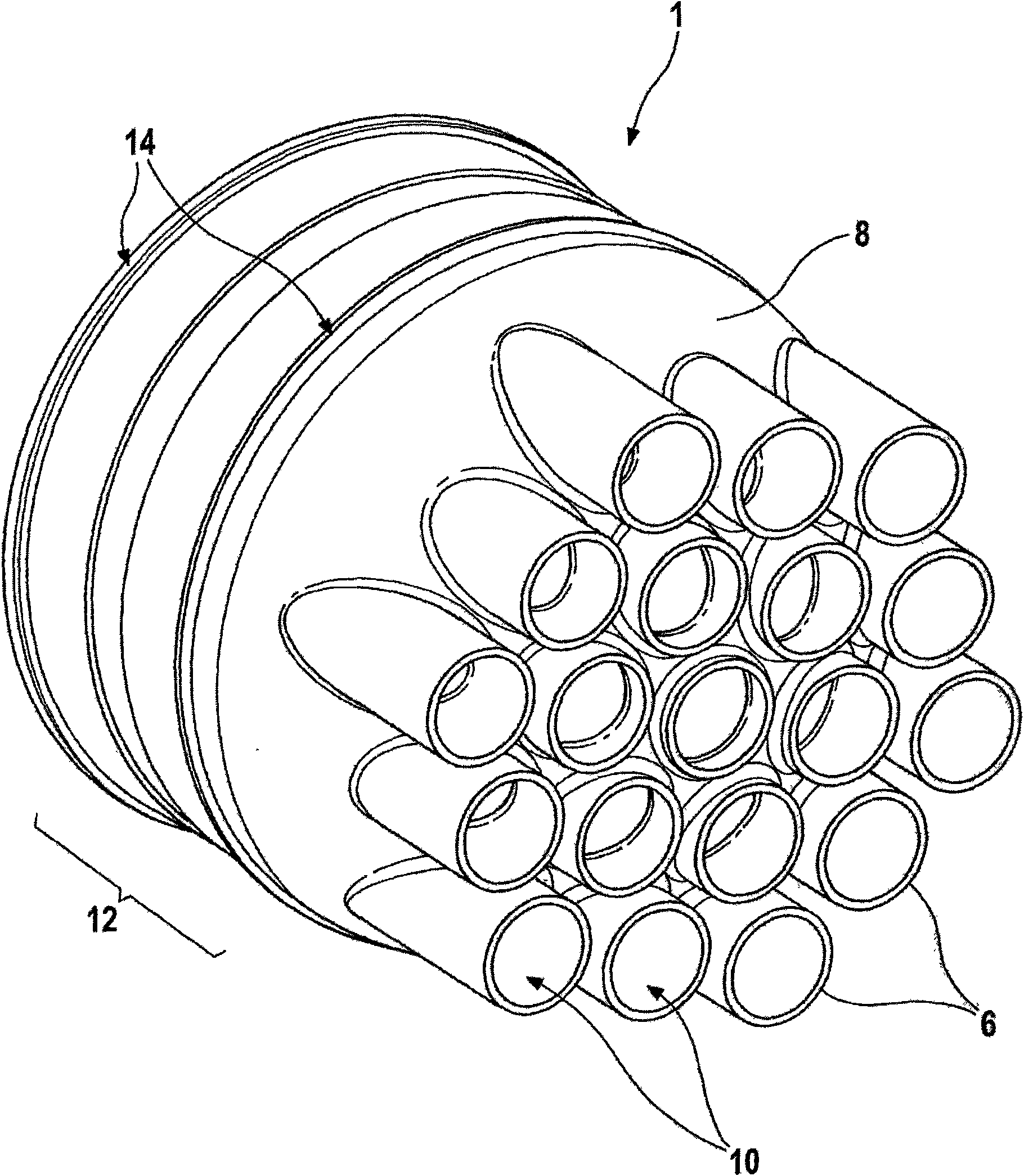

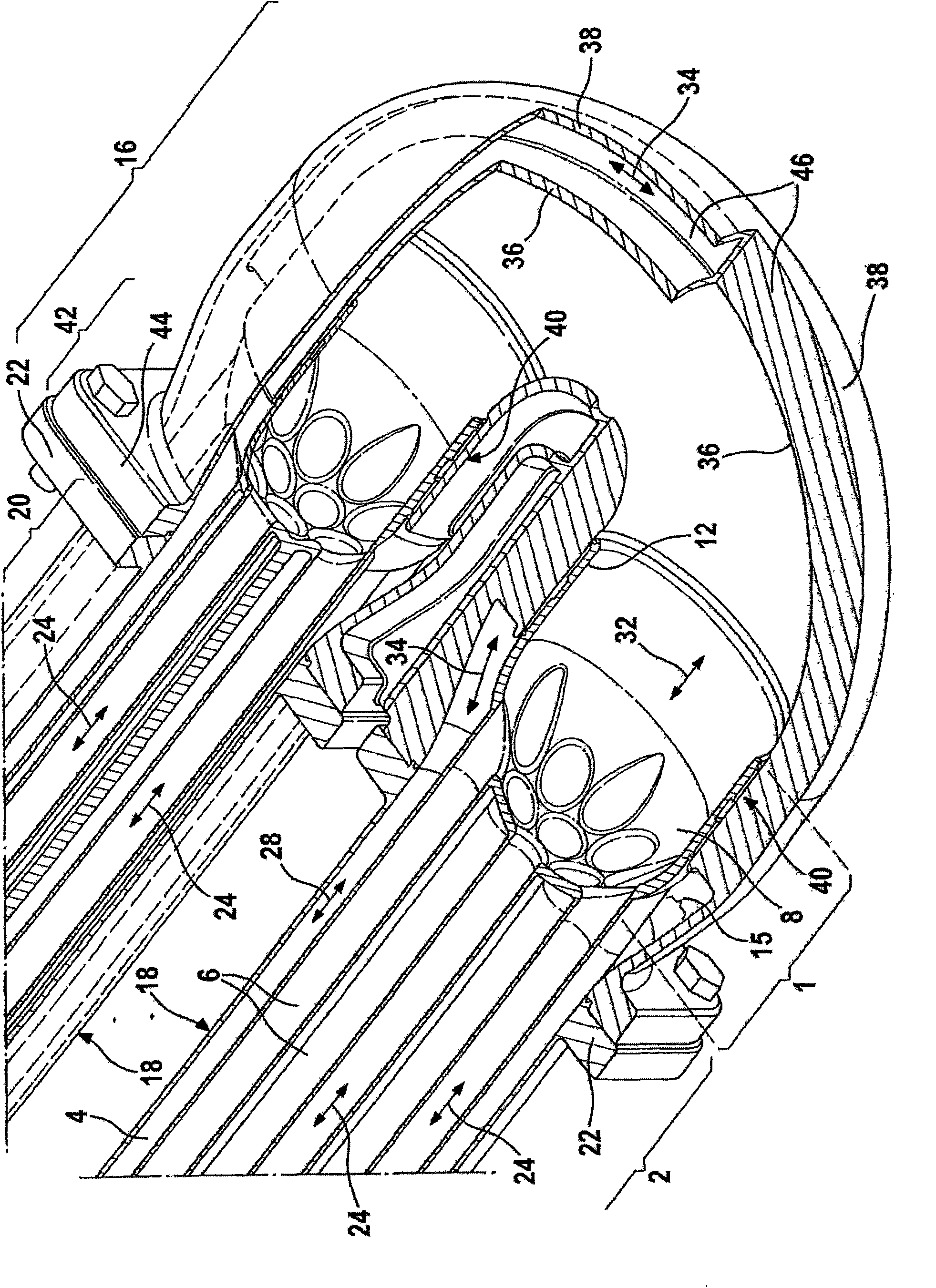

[0085] The end section 1 comprises a partial section 8 of substantially hemispherical configuration. On the peripheral surface of its outer appearance, the local section 8 is integrally connected to the heat transfer tube 6 of the tubular heat transfer device 2, the central axis of the hemisphere is oriented with the central axis of the tubular heat transfer device 2 or the heat transfer tube 6 respectively parallel. The end section 1 includes 19 through holes 10 corresponding in number and arrangement to the 19 heat transfer tubes 6 and in fluid communication with them. The through hole 10 has a substantially circular cross-section.

[0086] Inside the substantially hemispherical partial section 8 of the end section 1 of the tubular heat transfer device 2 , the inlet region of each through hole 10 has a circular shape.

[0087] The tip section 1 further comprises a substantially hollow cylindrical partial section 12 integrally connected to the hemispherical partial section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com