Gear type sludge dryer

A kind of sludge drying, gear type technology, applied in the direction of sludge treatment by temperature control, dewatering/drying/concentrating sludge treatment, etc., can solve the problems of high cost, complicated operation, small processing capacity, etc., and achieve fast drying speed. , The overall structure is compact and the drying force is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings.

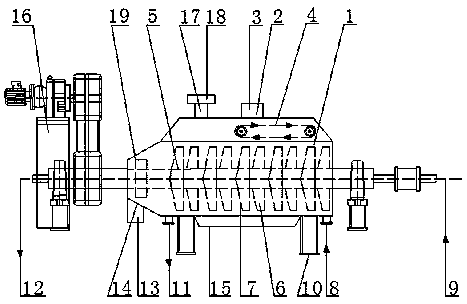

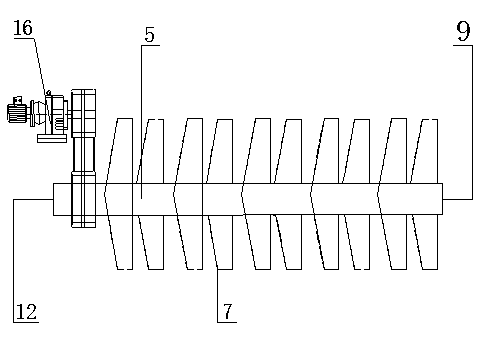

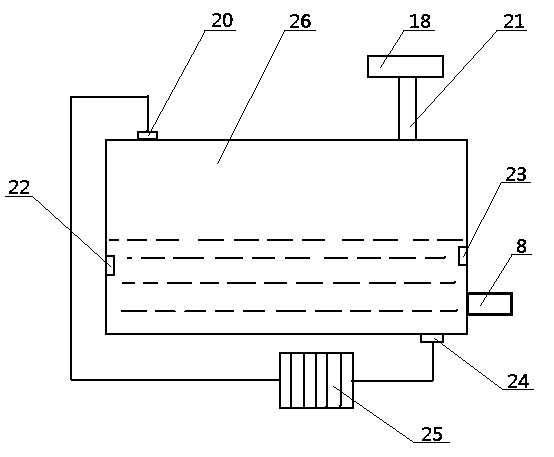

[0028] Such as figure 1 Shown is a gear sludge dryer. Its structure mainly includes a drying system consisting of a gear-type screw drive shaft 6, a first heat transfer medium inlet 8, a second heat transfer medium inlet 9, a first heat transfer medium outlet 11, and a second heat transfer medium outlet 12. A condensed water circulation device 15 is provided above and below the bracket 10; a sludge feed port 2 with a first automatic opening and closing baffle 3 and a sludge conveying device 4 is provided above the body 1, and the other end of the body is provided with a The drying mud cake outlet 13 of the second automatic opening and closing baffle plate 14; the top of the body 1 is also provided with a solvent vapor discharge port 17, and enters the circulating condensed water tank device 15 below the body through a pipeline for cooling, and the steam enters the ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com