High-temperature solid bulk cargo waste heat recovery device

A waste heat recovery device and high-temperature solid technology, applied in the field of heat exchange equipment, can solve problems such as low heat density, and achieve high heat exchange efficiency, uniform water temperature, and large temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

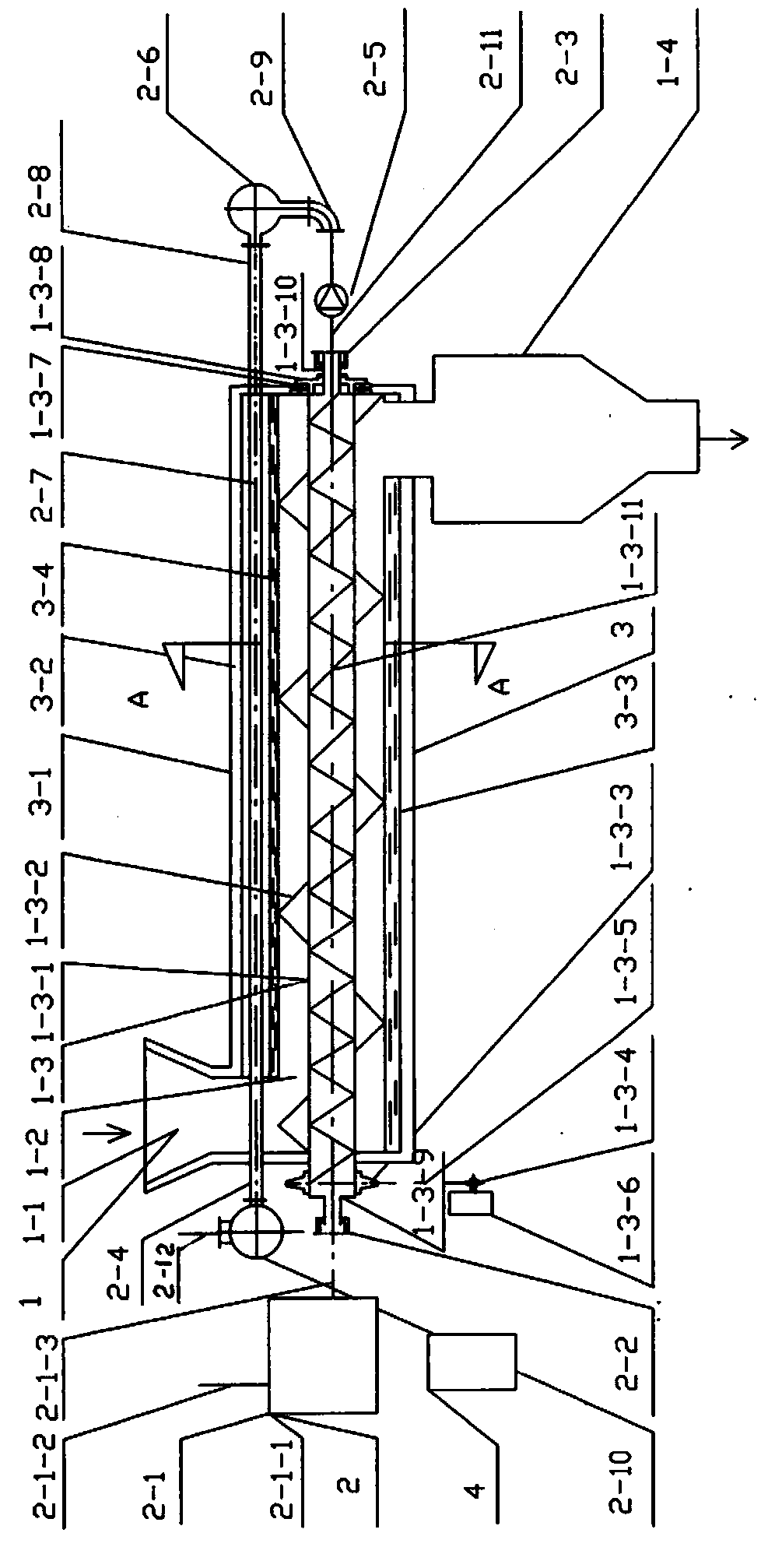

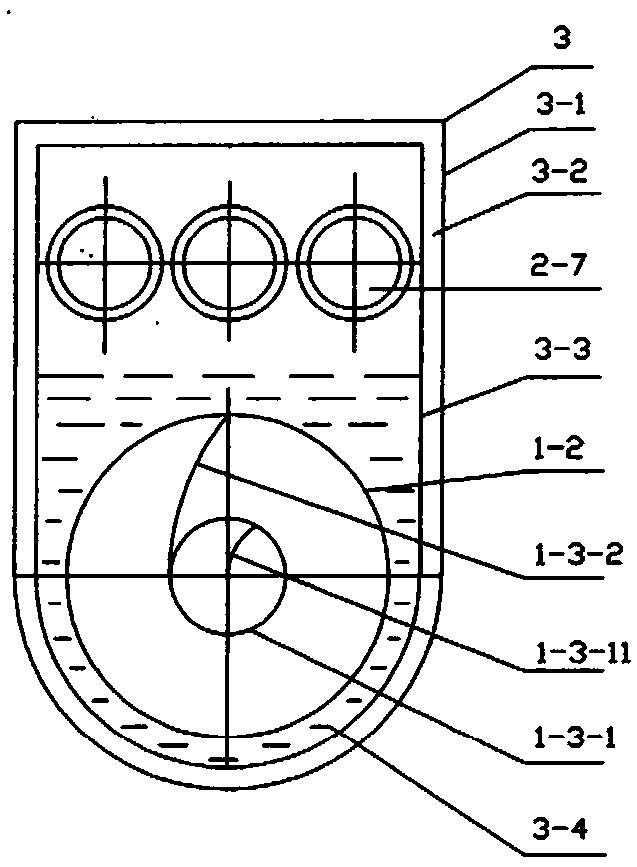

[0023] from figure 1 , figure 2 It can be seen that the high-temperature solid bulk waste heat recovery device is composed of a high-temperature solid bulk heat exchange system 1 , a water heat exchange system 2 , a high-temperature working fluid heat exchange system 3 , and an electric control cabinet 4 . In the high-temperature solid bulk material heat exchange system 1, the spiral propulsion cylinder 1-3-1 at the left end of the spiral propulsion cylinder water inlet pipe 1-3-9 and the left dynamic sealing device 2-2, the right end of the spiral propulsion cylinder water outlet pipe 1-3-10 and the The right dynamic sealing device 2-3 is a sliding fit connection, the water tank outlet pipe 2-1-3 in the water heat exchange system 2 is connected to the left dynamic sealing device 2-2, the high-pressure water pump inlet pipe 2-11 is connected to the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com