Green and efficient concentrated solution for hydraulic support system and preparation method of green and efficient concentrated solution

A technology of hydraulic support and concentrated solution, applied in the field of preparation of green and high-efficiency concentrated solution, can solve the problems of limited application of transmission medium, EDTA is not easy to degrade, and environmental pollution, etc., and achieves guaranteed service life, excellent low-temperature freeze-thaw performance, and corrosion inhibition performance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

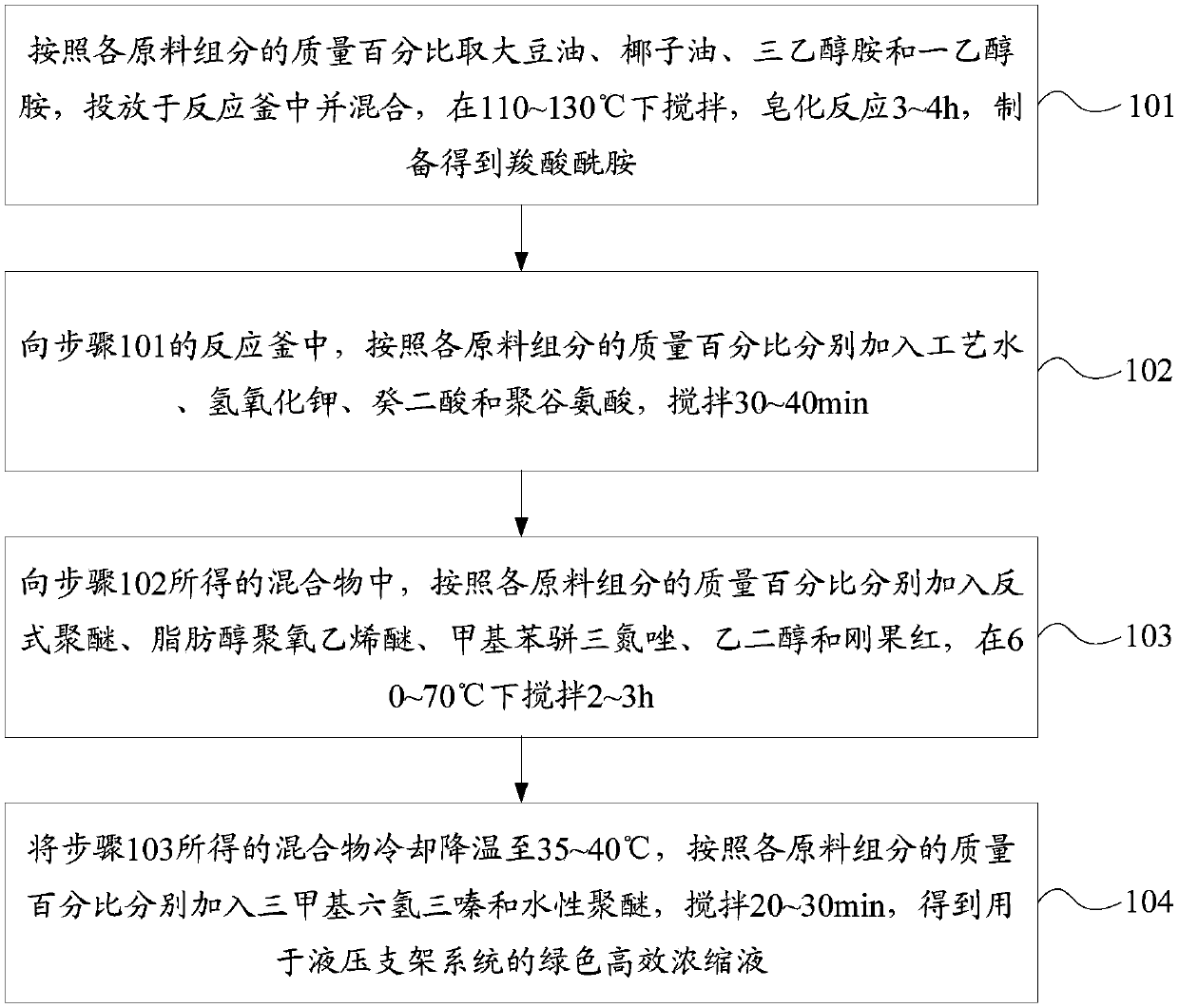

[0044] refer to figure 1 , which shows a flow chart of a method for preparing a green high-efficiency concentrate for a hydraulic support system according to an embodiment of the present invention, and the method specifically includes:

[0045] Step 101: Take soybean oil, coconut oil, triethanolamine and monoethanolamine according to the mass percentage of each raw material component, put them in a reaction kettle and mix them, stir at 110-130°C, saponify for 3-4 hours, and prepare carboxylic acid amides.

[0046] Step 102: Add process water, potassium hydroxide, sebacic acid and polyglutamic acid to the reactor in step 101 according to the mass percentage of each raw material component, and stir for 30-40 minutes.

[0047] Step 103, to the mixture obtained in step 102, respectively add trans polyether, fatty alcohol polyoxyethylene ether, tolyltriazole, ethylene glycol and Congo red according to the mass percentage of each raw material component, at 60- Stir at 70°C for 2-3...

Embodiment 1

[0052] Take 5% soybean oil, 3% coconut oil, 6% triethanolamine and 2% monoethanolamine according to the mass percentage of each raw material component, put them in the reaction kettle and mix them, stir at 110°C, saponify for 4 hours, and prepare carboxy acid amide.

[0053] Into the reactor in step 1, add 48.79% process water, 4% potassium hydroxide, 10% sebacic acid and 7% polyglutamic acid respectively according to the mass percentage of each raw material component, and stir for 30 minutes.

[0054] In the mixture obtained in step 2, add 2% trans polyether, 1% fatty alcohol polyoxyethylene ether, 0.1% tolyltriazole, 10% ethylene glycol and 0.01% % Congo red, stirred at 60°C for 2h.

[0055] Cool the mixture obtained in step 3 to 35°C, add 1% trimethylhexahydrotriazine and 0.1% water-based polyether according to the mass percentage of each raw material component, and stir for 20 minutes to obtain a green and efficient solution for hydraulic support systems. Concentrate.

Embodiment 2

[0057] Take 8% soybean oil, 5% coconut oil, 10% triethanolamine and 4% monoethanolamine according to the mass percentage of each raw material component, put them in the reaction kettle and mix them, stir at 130°C, saponify for 3 hours, and prepare carboxy acid amide.

[0058] Into the reactor in step 1, add 27.38% process water, 6% potassium hydroxide, 12% sebacic acid and 10% polyglutamic acid respectively according to the mass percentage of each raw material component, and stir for 40 minutes.

[0059] In the mixture obtained in step 2, add 3% trans polyether, 2% fatty alcohol polyoxyethylene ether, 0.3% tolyltriazole, 10% ethylene glycol and 0.02 % Congo red, stirred at 70°C for 3h.

[0060] Cool the mixture obtained in step 3 to 40°C, add 2% trimethylhexahydrotriazine and 0.3% water-based polyether according to the mass percentage of each raw material component, and stir for 30 minutes to obtain a green and efficient solution for hydraulic support systems. Concentrate. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com