Polycarbonate composition for LDS with good thermal stability

A technology of polycarbonate and composition, which is applied in the field of polycarbonate composition for LDS, can solve the problems such as loss of practical value of materials, achieve good oxidation resistance and processing performance, good thermal stability, and inhibit thermal degradation and oxidation Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

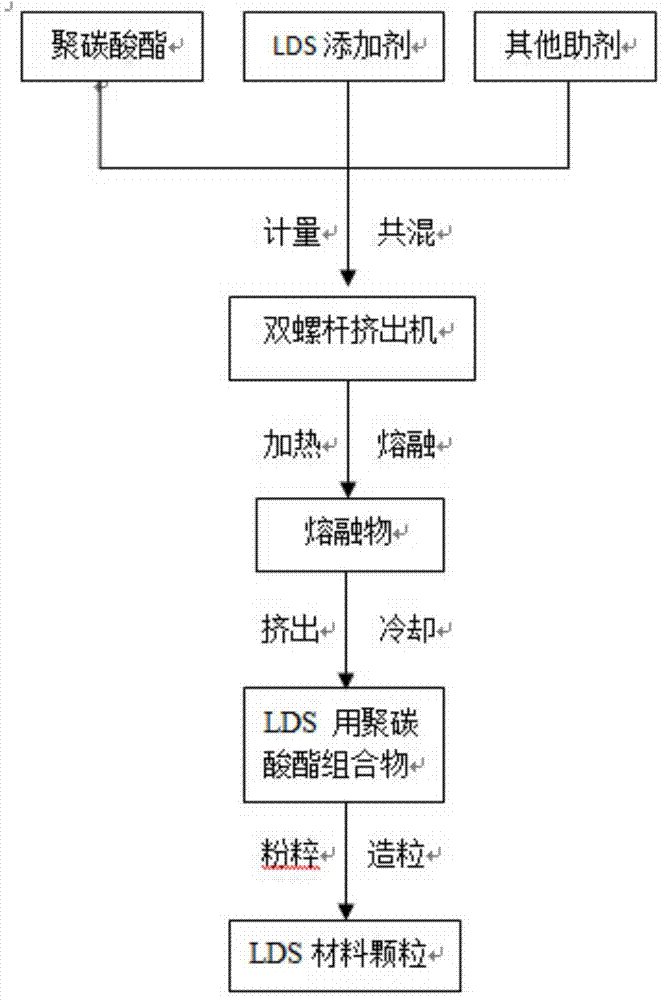

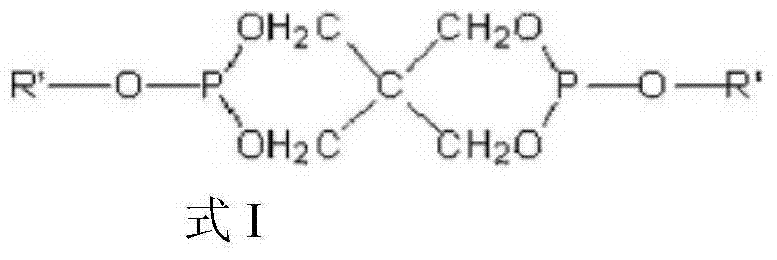

Method used

Image

Examples

Embodiment 1

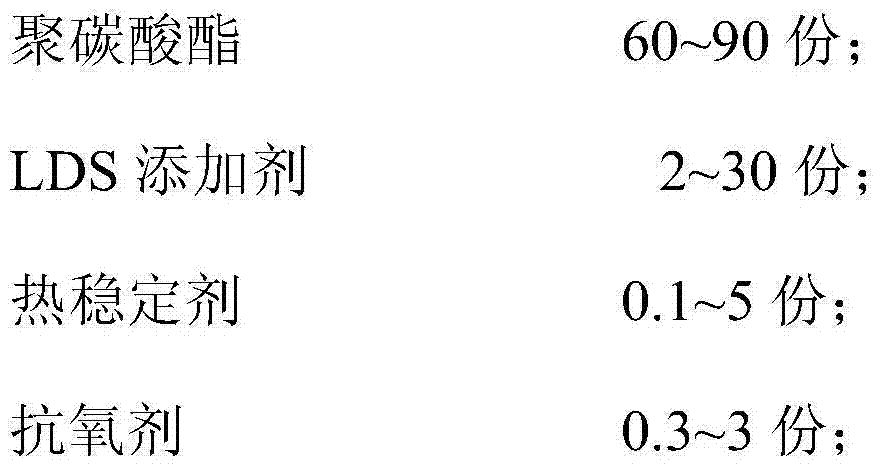

[0069] Embodiment 1: The polycarbonate composition for LDS of this embodiment, by mass parts, includes components:

[0070]

[0071]

[0072] The MFR of polycarbonate in this example is 5g / 10min, 300°C / 1.5Kg.

[0073] The preparation method of polycarbonate composition for LDS in the present embodiment is as follows:

[0074] In terms of parts by mass, 90 parts of polycarbonate, 4 parts of silicone core-shell copolymer toughening agent, 2 parts of ethylene acrylic acid graft copolymer compatibilizer, 5 parts of LDS additive, 0.5 part of heat stabilizer ZnO, hydrotalcite 2 parts, 3290.3 parts of ultraviolet light absorber, 10760.3 parts of antioxidant, 1681 parts of antioxidant, 0.2 part of silicone powder are pre-mixed evenly, put into the heating and melting of the twin-screw extruder, obtain the melt, extrude, and cool 1. Obtain the polycarbonate composition for LDS, pulverize it, and obtain LDS material granules.

Embodiment 2

[0075] Embodiment 2: The polycarbonate composition for LDS of the present embodiment, by mass parts, includes components:

[0076]

[0077]

[0078] Among them, the MFR of polycarbonate is 10g / 10min, 300°C / 1.5Kg.

[0079] The preparation method of polycarbonate composition for LDS in the present embodiment is as follows:

[0080]In parts by mass, 80 parts of polycarbonate, 8 parts of MBS core-shell copolymer toughening agent, 3 parts of maleic anhydride graft copolymer compatibilizer, 12 parts of LDS additive, 2 parts of heat stabilizer ZnS, hydrotalcite 2 parts, 54110.2 parts of ultraviolet light absorber, 10760.5 parts of antioxidant, 1 part of antioxidant 627A, 0.2 part of silicone powder are pre-mixed evenly, and put into the heating and melting of twin-screw extruder to obtain the melt, extrude, Cool to obtain the polycarbonate composition for LDS, and pulverize it to obtain LDS material granules.

Embodiment 3

[0081] Embodiment 3: The polycarbonate composition for LDS of the present embodiment, by mass parts, includes components:

[0082]

[0083] Among them, the MFR of polycarbonate is 12g / 10min, 300°C / 1.5Kg.

[0084] The preparation method of polycarbonate composition for LDS in the present embodiment is as follows:

[0085] In parts by mass, 60 parts of polycarbonate, 15 parts of ABS toughening agent, 4 parts of PTW compatibilizer, 20 parts of LDS additive, 1 part of heat stabilizer nano zinc oxide, 3 parts of hydrotalcite, ultraviolet light absorber 2340.2 parts, 17900.3 parts of antioxidant, 0.7 part of antioxidant S-9228T, 0.3 part of modified silicone powder, 0.5 part of oxidized polyethylene wax, pre-mixed evenly, put into the heating and melting of twin-screw extruder to obtain the melt , extruding, and cooling to obtain the polycarbonate composition for LDS, and pulverize it to obtain LDS material granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com