Al-Mg-Si type tank edge casting material and preparation method and application thereof

An aluminum-magnesium-silicon and castable technology, which is applied in the field of steel-making ladle refractories, can solve problems such as cracks and poor thermal stability, and achieve the effects of stable thermodynamic performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

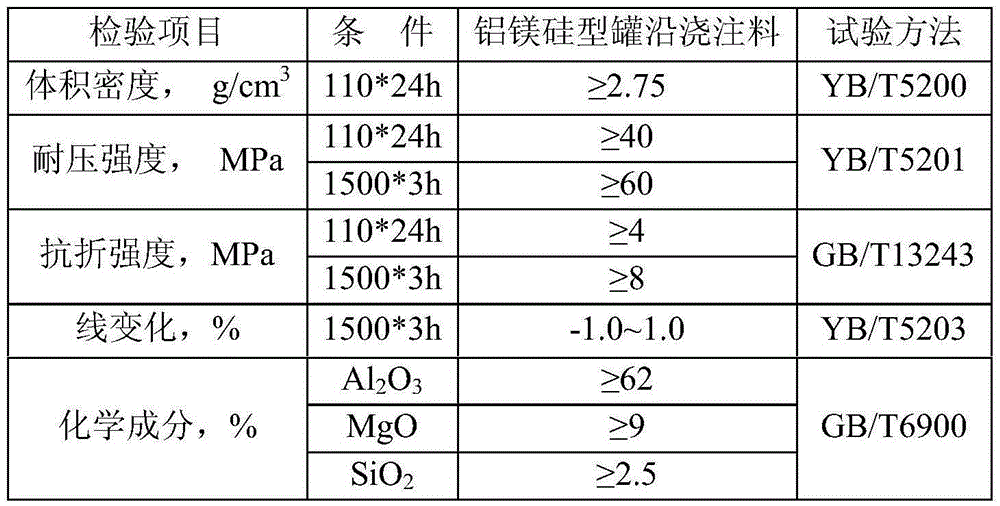

Examples

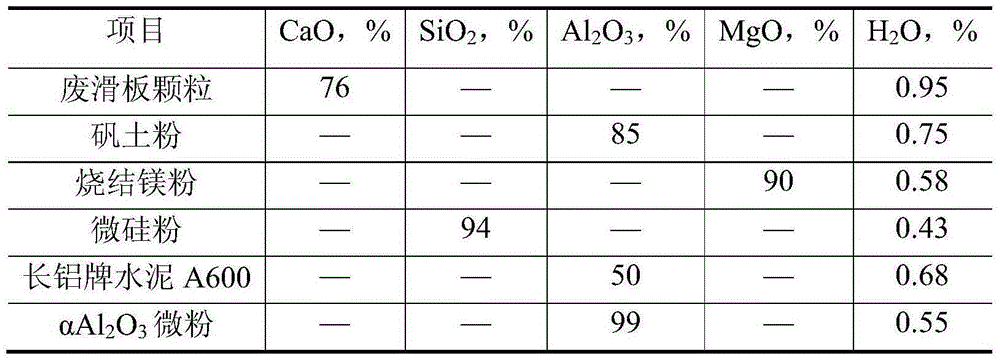

Embodiment 1

[0036] Put 45 parts by weight of 0.088mm-3mm waste skateboard particles and 25 parts by weight of 3-8mm waste skateboard particles that have passed the inspection into the drum mixer for mixing. After mixing for 2 minutes, add 8 parts by weight of alumina Powder, 9 parts by weight of sintered magnesium powder, 5 parts by weight of Changlu brand A600 cement, 3 parts by weight of silica dust powder, and 5 parts by weight of α-alumina micropowder are sent into a drum mixer for mixing and stirring. After stirring for 4 minutes, put the mixed material into a dry ton bag through a three-way valve discharge device, pack it at 500Kg / bag, fasten the opening mark and put it in storage for later use, and take samples to test the aluminum-magnesium-silicon type tank along the pouring The physical and chemical indicators of the materials (see Table 3 for the test results), and after passing the test, they are transported to the repairing work area of Xichang Steel Vanadium Steelmaking Pla...

Embodiment 2

[0040] Send 50 parts by weight of 0.088mm-3mm waste skateboard particles and 20 parts by weight of 3-8mm waste skateboard particles that have passed the inspection into a drum mixer for mixing. After mixing for 2 minutes, add 5 parts by weight of alumina Powder, 12 parts by weight of sintered magnesium powder, 3 parts by weight of Changlu brand A600 cement, 5 parts by weight of silica dust powder, and 5 parts by weight of α-alumina micropowder are sent into a drum mixer for mixing and stirring. After stirring for 4 minutes, put the mixed material into a dry ton bag through the discharge device connected with the three-way valve, pack it at 500Kg / bag, tie the opening mark and put it into the warehouse for standby, and take samples to test the aluminum-magnesium-silicon type tank Along the physical and chemical indicators of castables (see Table 4 for test results), after passing the test, they are transported to the repairing work area of Xichang Steel Vanadium Steelmaking Pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com