Varied concentration mixed working medium auto-cascade refrigerator

A technology of mixed working fluid and variable concentration, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve problems such as high compressor pressure ratio and exhaust temperature, high compressor exhaust pressure, and compressor failure to start , to achieve the effect of reducing the start-up pressure, increasing the cooling rate, and optimizing the initial cooling stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

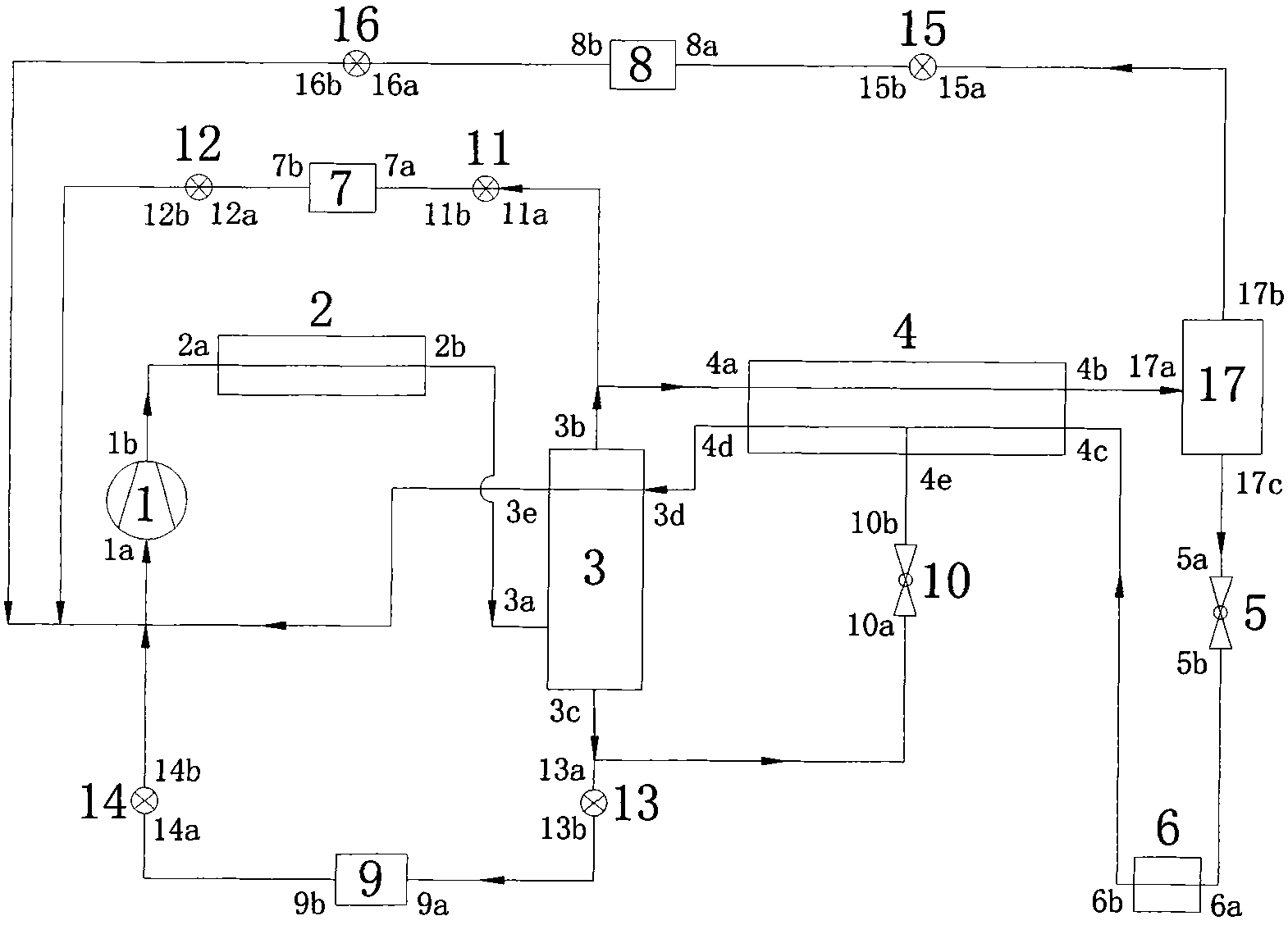

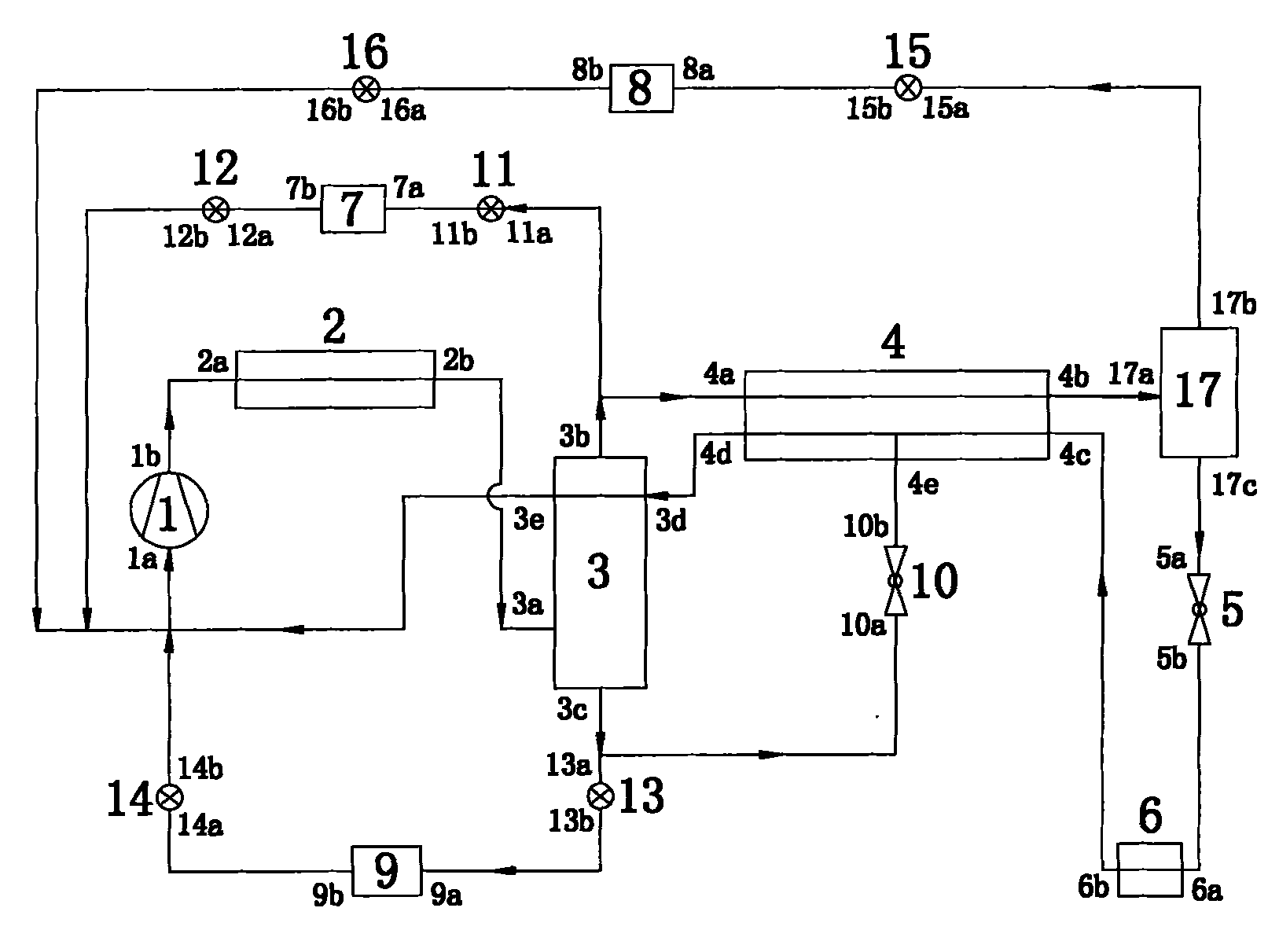

[0012] As shown in the attached figure, the self-cascade refrigeration system of variable concentration mixed working medium is divided into four parts: normal concentration circuit, first variable concentration circuit, second variable concentration circuit and third variable concentration circuit.

[0013] Normal concentration circuit: the exhaust port 1b of the compressor 1 is connected with the inlet port 2a of the condenser 2, the outlet 2b of the condenser 2 is connected with the first port 3a of the rectification device 3, and the second port 3b of the rectification device 3 respectively connected to the first port 11a of the first cut-off valve 11 and the first port 4a of the regenerator 4; The first port 10a of the element 10 is connected, the fourth port 3d of the rectification device 3 is connected with the fourth port 4d of the regenerator 4, and the fifth port 3e of the rectification device 3 is connected with the second port of the fourth stop valve 14 respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com