Rectifying type variation-concentration self-overlaying gas liquefaction system

A variable concentration, self-cascading technology, used in refrigeration and liquefaction, fluid circulation arrangements, lighting and heating equipment, etc., can solve problems such as high compressor pressure ratio and discharge temperature, reduced compressor life, and refrigeration system paralysis. , to achieve the effect of improving the exhaust temperature, reducing the pressure ratio, and reducing the unit liquefaction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

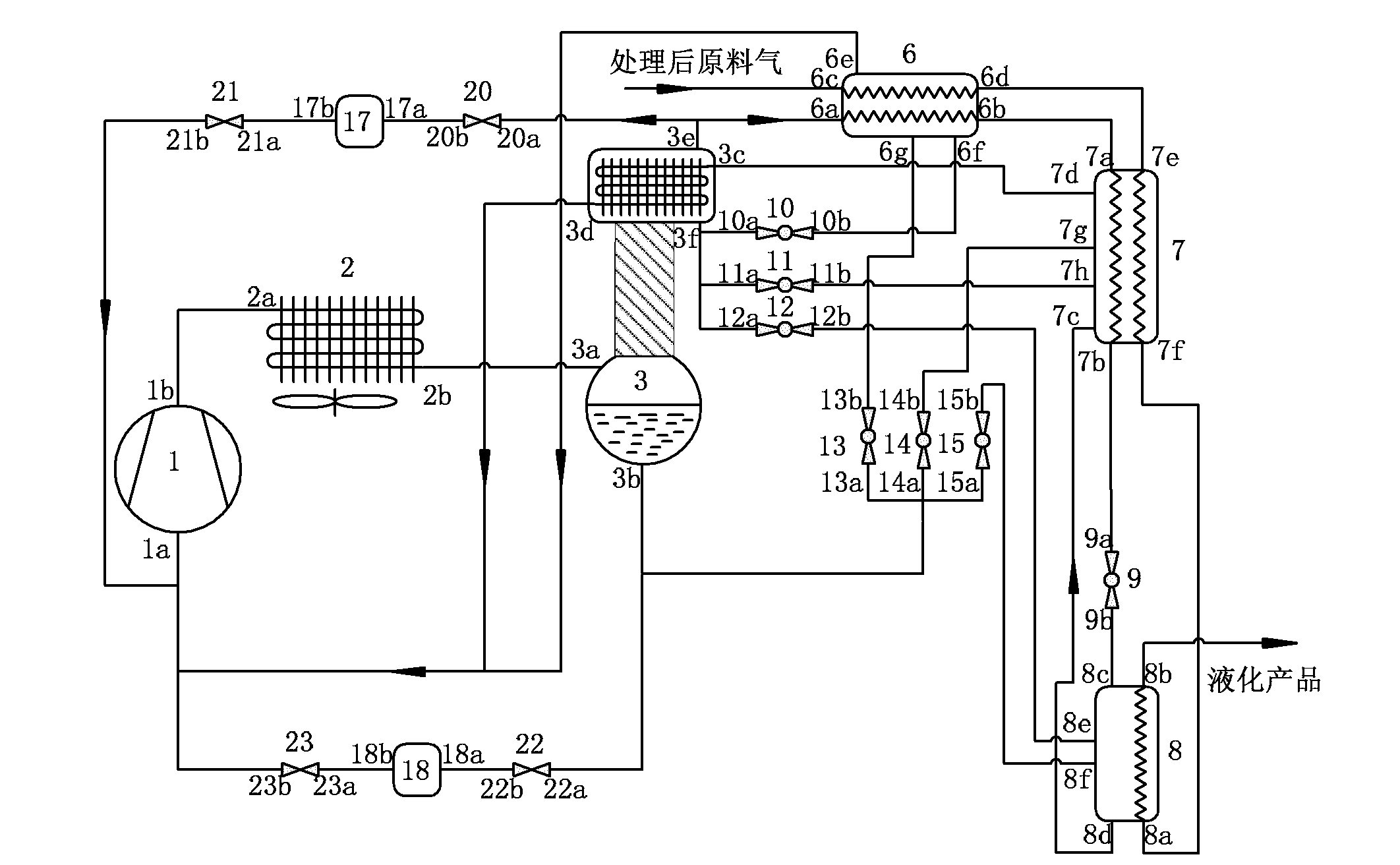

[0029] Such as figure 1As shown, a rectification-type variable concentration self-cascading gas liquefaction system includes four parts: the normal concentration circuit, the first variable concentration circuit, the second variable concentration circuit and the feed gas liquefaction circuit. The following describes each circuit in detail illustrate.

[0030] (1) Normal concentration circuit:

[0031] The normal concentration circuit includes compressor 1, condenser 2, rectification device 3, first heat exchanger 6, second heat exchanger 7, third heat exchanger 8, first throttling element 9, second throttling element 10. The third throttling element 11 , the fourth throttling element 12 , the fifth throttling element 13 , the sixth throttling element 14 , and the seventh throttling element 15 . The rectification device 3 includes a rectification tower and a tower top heat exchanger communicated with the top of the rectification section of the rectification tower. Both the f...

Embodiment 2

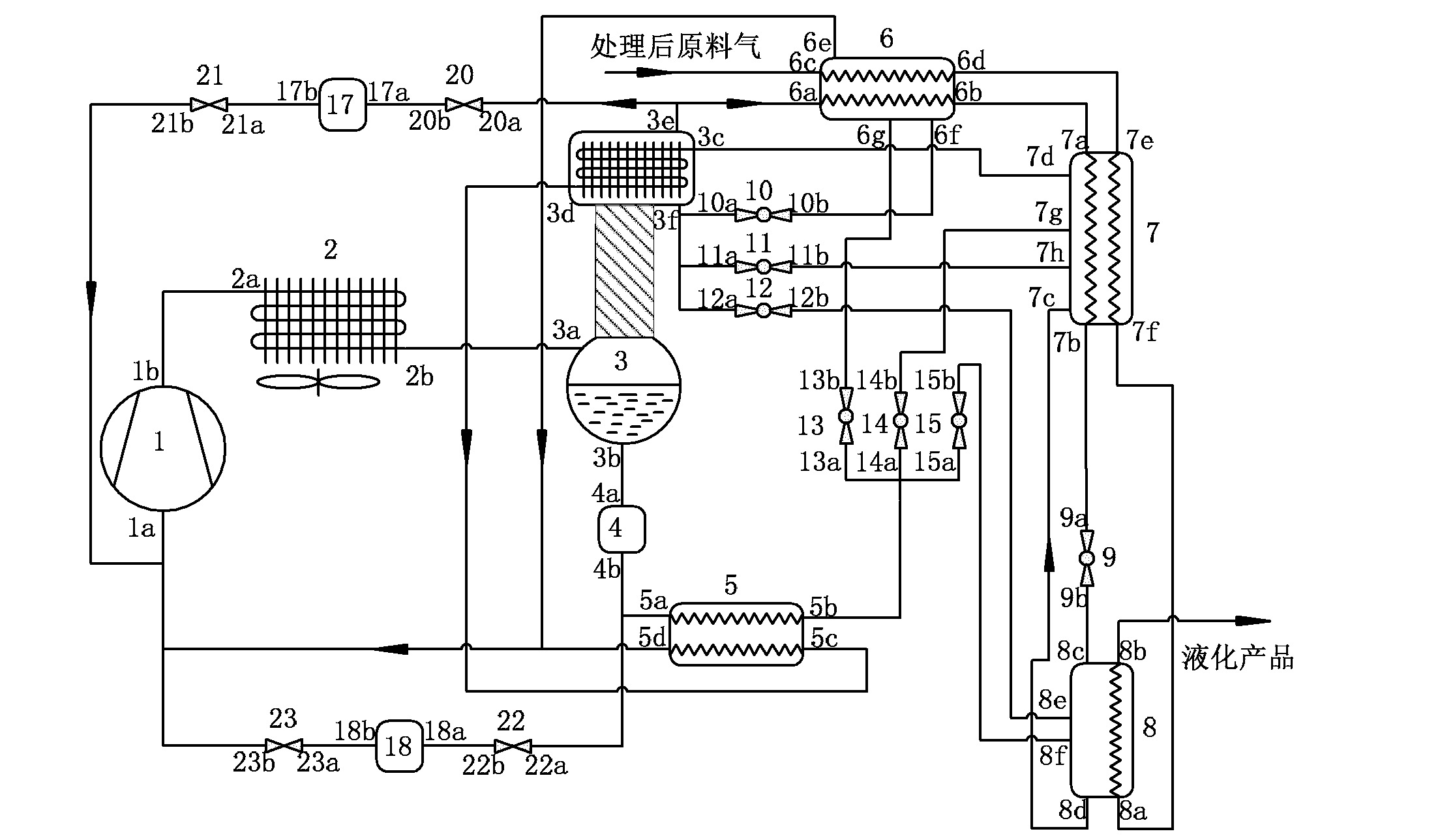

[0061] Such as figure 2 As shown, the structure and connection method are the same as those of the embodiment, except that a dry filter is provided between the bottom of the rectification tower and the fifth throttling element 13 or the sixth throttling element 14 or the seventh throttling element 15 4 and tank bottom heat exchanger 5. Wherein, the liquid outlet 3b at the bottom of the rectifying tower of the rectifying device 3 is first connected with the feed port 4a of the dry filter 4, and the discharge port 4b of the dry filter 4 is respectively connected with two branches arranged in parallel, wherein One branch is connected with the feed port 22a of the third shut-off valve 22, and the other branch is connected with the inlet end 5a of one of the pipes in the bottom heat exchanger 5, and the outlet end 5b of the pipe is respectively connected with the fifth The feed port of the throttling element 13 or the sixth throttling element 14 or the seventh throttling element ...

Embodiment 3

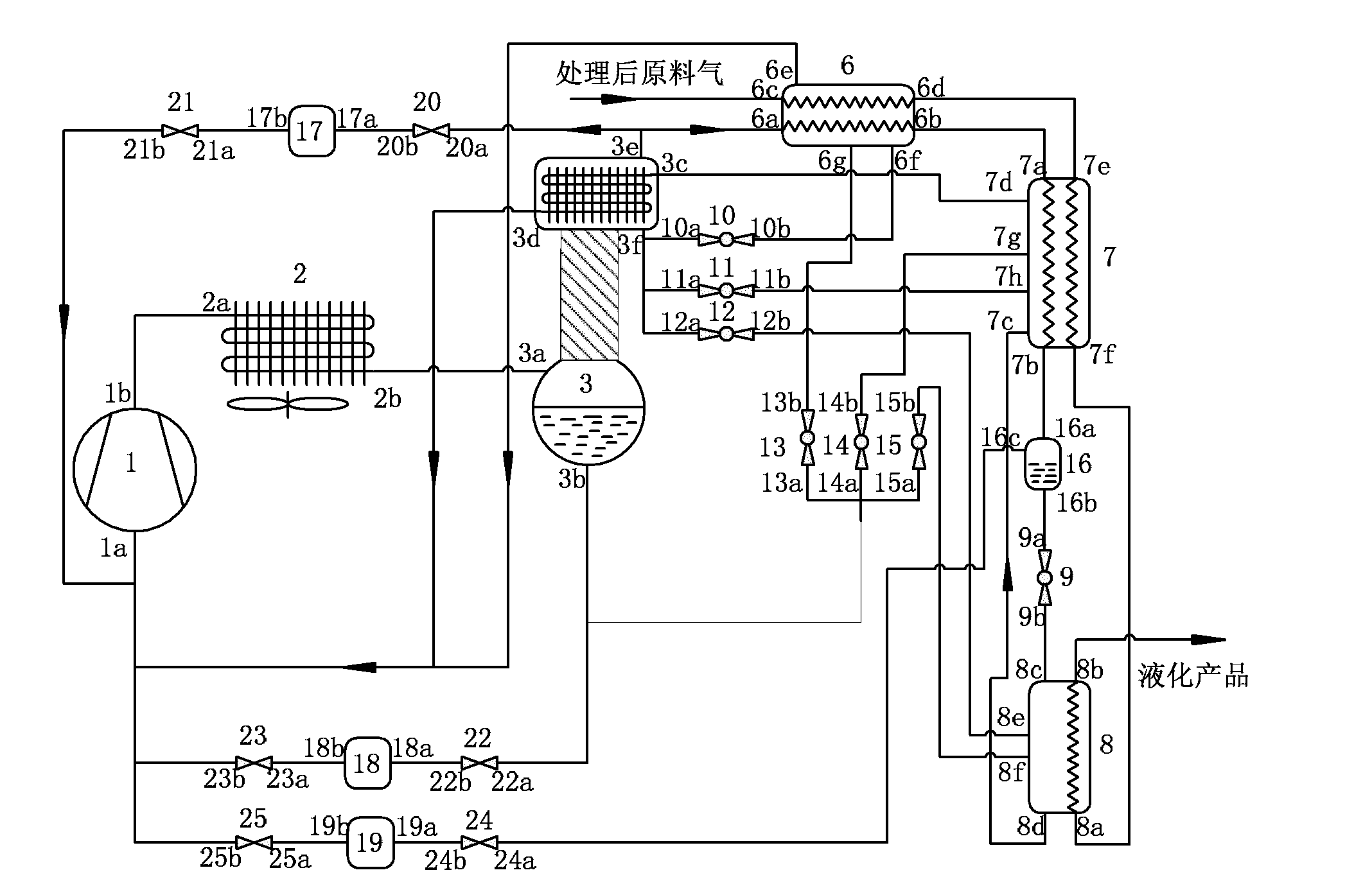

[0064] Such as image 3 As shown, the structure and connection method are the same as those of Embodiment 1, the difference is that: on the pipeline between the inlet of the first throttling element 9 and the outlet end of the refrigerant pipeline of the second heat exchanger 7, a A gas-liquid separator 16; a third variable concentration circuit is provided between the gas-liquid separator 16 and the suction port of the compressor 1; the third variable concentration circuit is composed of the fifth cut-off valve 24, the second gas storage circuit connected in series successively The tank 19 and the sixth stop valve 25 are composed; wherein, the feed port of the fifth stop valve 24 is communicated with the gas section of the gas-liquid separator 16 inner cavity, and the discharge port 24b is connected with the feed port of the second gas storage tank 19; The feed port 25a of the sixth cut-off valve 25 is connected with the discharge port of the second gas storage tank 19 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com