Modified low density polyethylene nanocomposite material used for 3D printing, and preparation method thereof

A technology of low-density polyethylene and nano-composite materials, which is applied in the field of modified low-density polyethylene nano-composite materials and its preparation, can solve the problems of difficult handling, low heat resistance, low crystal melting point, etc., and achieves easy industrial production. , the effect of increased impact resistance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

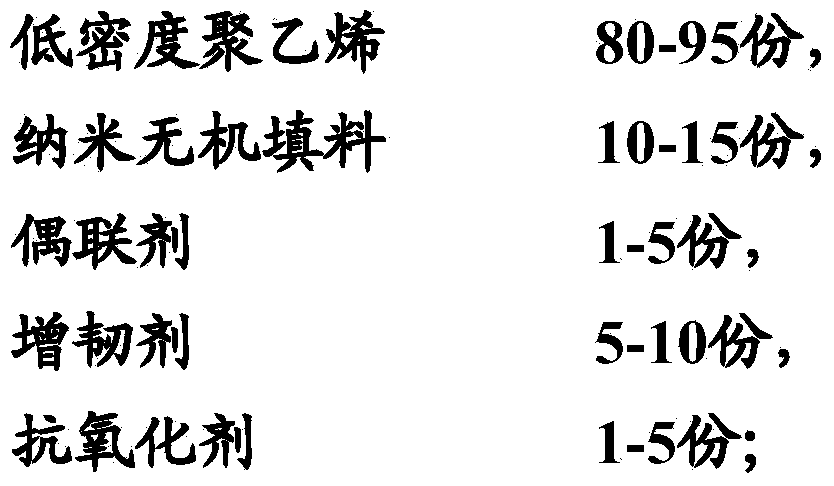

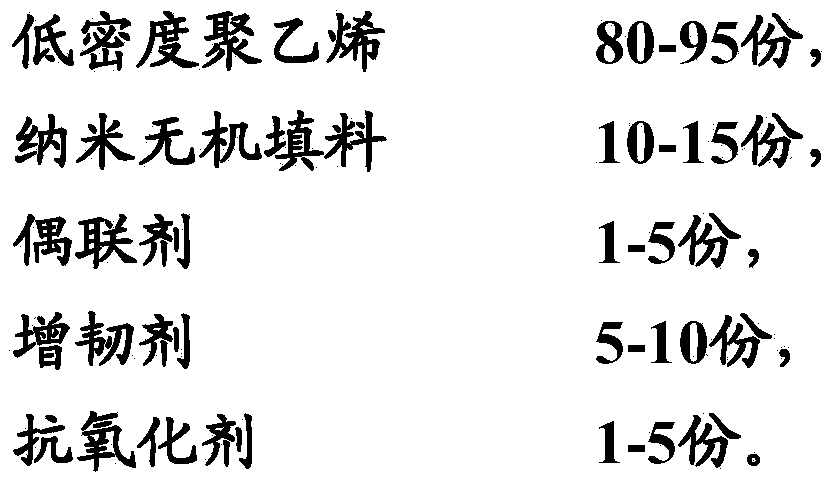

Method used

Image

Examples

Embodiment 1

[0054] 1) Dissolving 5 parts of titanate coupling agent in an appropriate amount of absolute ethanol to prepare a coupling agent solution with a concentration of 1-2%.

[0055] 2) Drop the prepared coupling agent solution into 10 parts of carbon nanotube inorganic filler, stir for 24 hours in a planetary ball mill with a rotating speed of 200 r / min, take it out and bake in an oven at 80° C. for 12 hours.

[0056] 3) The carbon nanotube inorganic filler prepared in step 2), 80 parts of low-density polyethylene, 5 parts of toughening agent polyacrylate, and 2 parts of antioxidant 1010 were added to a high-speed mixer and mixed uniformly .

[0057] 4) Add the mixture obtained in step 3) into a twin-screw extruder with an aspect ratio of 36 to extrude and granulate to make LDPE pellets. The residence time of the material in the extruder was 3 minutes. The temperature of the extruder is sequentially set as follows: feeding section 150°C, melting section 160°C, homogenizing sectio...

Embodiment 2

[0062] 1) Dissolving 5 parts of titanate coupling agent in an appropriate amount of absolute ethanol to prepare a coupling agent solution with a concentration of 1-2%.

[0063] 2) Drop the prepared coupling agent solution into 10 parts of nano-SiO 2 In the inorganic filler, stir in a planetary ball mill with a rotation speed of 200r / min for 24h, take it out and bake in an oven at 80°C for 12h.

[0064] 3) the nano-SiO that will be made in step 2) 2 Inorganic filler, 80 parts of low-density polyethylene, 5 parts of toughening agent polyacrylate, and 1 part of antioxidant 1096 were added to a high-speed mixer and mixed evenly.

[0065] 4) Add the mixture obtained in step 3) into a twin-screw extruder with an aspect ratio of 36 to extrude and granulate to make LDPE pellets. The residence time of the material in the extruder was 3 minutes. The temperature of the extruder is set in turn: 155°C in the feeding section, 165°C in the melting section, 175°C in the homogenizing sectio...

Embodiment 3

[0070] 1) Dissolving 5 parts of silane coupling agent in an appropriate amount of absolute ethanol to prepare a coupling agent solution with a concentration of 1-2%.

[0071] 2) Drop the prepared coupling agent solution into 10 parts of nano-TiO 2 In the inorganic filler, stir in a planetary ball mill with a rotation speed of 200r / min for 24h, take it out and bake in an oven at 80°C for 12h.

[0072] 3) the nano-TiO that will be made in step 2) 2 Inorganic filler, 85 parts of low-density polyethylene, 5 parts of toughening agent polyester, and 5 parts of antioxidant 168 were added to a high-speed mixer and mixed evenly.

[0073] 4) Add the mixture obtained in step 3) into a twin-screw extruder with an aspect ratio of 36 to extrude and granulate to make low-density polyethylene nanocomposite pellets. The residence time of the material in the extruder was 5 minutes. The temperature of the extruder is set in turn: 150°C in the feeding section, 165°C in the melting section, 170...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com