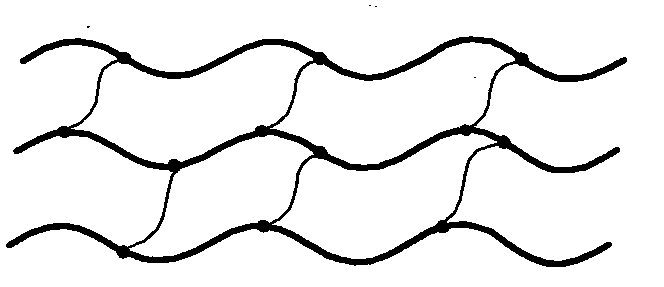

PA6-serial thermoplastic elastomer with high resilience and preparation method thereof

A thermoplastic elastomer and resilience technology, applied in the field of high resilience PA6 series thermoplastic elastomer and its preparation, can solve the problem of weak physical cross-linking point binding force of hard segments, easy slippage of macromolecular chains, and poor product resilience. and other problems, to achieve the effects of excellent resilience, high molecular weight and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

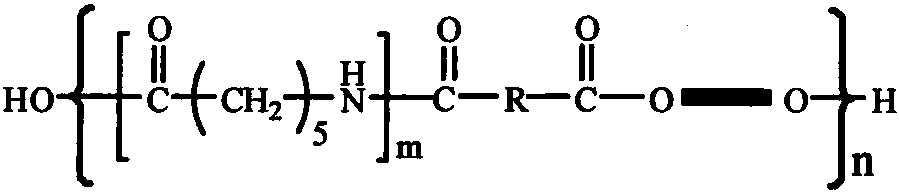

[0055] A high-resilience PA6-based thermoplastic elastomer, the preparation method of which comprises: preparing a double-terminated carboxyl PA6 prepolymer by hydrolytic ring-opening polymerization, then adding diol for esterification, and finally adding polyglycol and a cross-linking agent for reaction, thus preparing high resilience PA6 series thermoplastic elastomers.

[0056] The preparation method of the above-mentioned high resilience PA6 series thermoplastic elastomer is:

[0057] The first step: prepare double-terminal carboxyl PA6 prepolymer by hydrolytic ring-opening polymerization method: add 100g caprolactam, 5g deionized water, 1g 4-aminobutyric acid, 9.1g terephthalic acid, 0.1g phosphoric acid into a 500mL polymerization kettle Triphenyl ester. Nitrogen was introduced into the kettle to replace the air in the kettle, and then the pressure was increased to 8 bar, and the temperature was raised to 270° C. for 1.5 hours at a stirring speed of 200 r / min. Then the...

Embodiment 2

[0061] A high-resilience PA6-based thermoplastic elastomer, the preparation method of which comprises: preparing a double-terminated carboxyl PA6 prepolymer by hydrolytic ring-opening polymerization, then adding diol for esterification, and finally adding polyglycol and a cross-linking agent for reaction, thus preparing high resilience PA6 series thermoplastic elastomers.

[0062] The preparation method of the above-mentioned high resilience PA6 series thermoplastic elastomer is:

[0063] The first step: prepare double-terminal carboxyl PA6 prepolymer by hydrolytic ring-opening polymerization method: add 100g caprolactam, 5g deionized water, 1g 6-aminocaproic acid, 9.1g terephthalic acid, 0.1g phosphoric acid into a 500mL polymerization kettle Triphenyl ester. Nitrogen was introduced into the kettle, and the pressure in the kettle was replaced to 8 bar. At a stirring speed of 200r / min, the temperature was raised to 270°C. After 1.5 hours of reaction, the pressure was reduce...

Embodiment 3

[0067] A high-resilience PA6-based thermoplastic elastomer, the preparation method of which comprises: preparing a double-terminated carboxyl PA6 prepolymer by hydrolytic ring-opening polymerization, then adding diol for esterification, and finally adding polyglycol and a cross-linking agent for reaction, thus preparing high resilience PA6 series thermoplastic elastomers.

[0068] The preparation method of the above-mentioned high resilience PA6 series thermoplastic elastomer is:

[0069] The first step: prepare double-terminal carboxyl PA6 prepolymer by hydrolytic ring-opening polymerization method: add 100g caprolactam, 5g deionized water, 1g 5-aminovaleric acid, 4.7g oxalic acid, 0.1g Irganox1010 into a 500mL polymerization kettle. Nitrogen gas was introduced into the kettle, and the pressure was increased to 6 bar after replacing the air in the kettle. At a stirring speed of 200r / min, the temperature was raised to 270°C. After 1.5 hours of reaction, the pressure was redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com