Pulse electrospray ion source, pulse sample injection method and mass spectrum detection system

A pulsed electricity and ion source technology, applied in the field of analytical instruments, can solve the problem of low sample utilization rate, and achieve the effects of short response time, improved utilization rate, and small sample consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

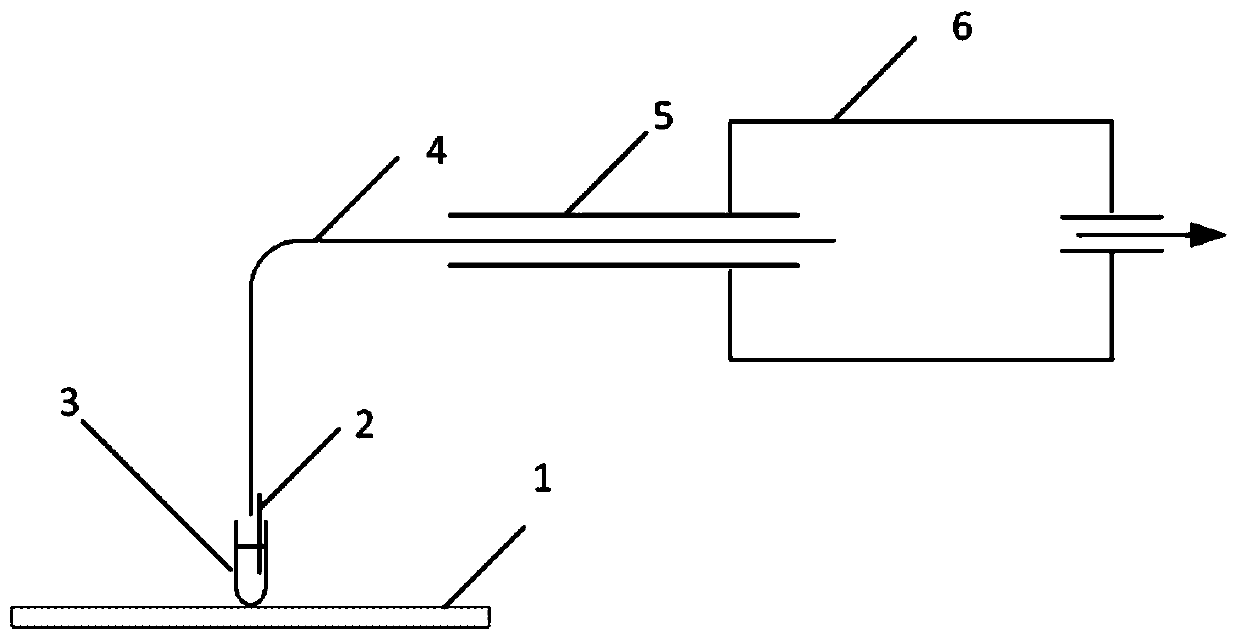

[0043] Such as figure 1 Shown is a schematic structural view of the pulsed electrospray ion source in this specific embodiment. It includes a sampling capillary 4, a carrier gas channel 5, an elevating platform 1, an electrode 2, a centrifuge tube 3, and a low-pressure chamber 6.

[0044] One end of the sampling capillary 4 is used as the sampling end, and the other end is placed in the low-pressure cavity 6; the sampling capillary 4 passes through the carrier gas passage 5; the electrode 2 is inserted into the solution in the centrifuge tube 3; the The electrode 2 and the centrifuge tube 3 are placed together on the lifting platform 1; the lifting platform 1 can move up and down or three-dimensionally; the other end of the low-pressure cavity 6 is connected to the sample inlet of the mass spectrometer. The capillary 4 is in pulsed contact with the sample to be measured, and self-priming sample injection can generate pulsed electrospray in the low-pressure chamber 6, so that ...

Embodiment 2

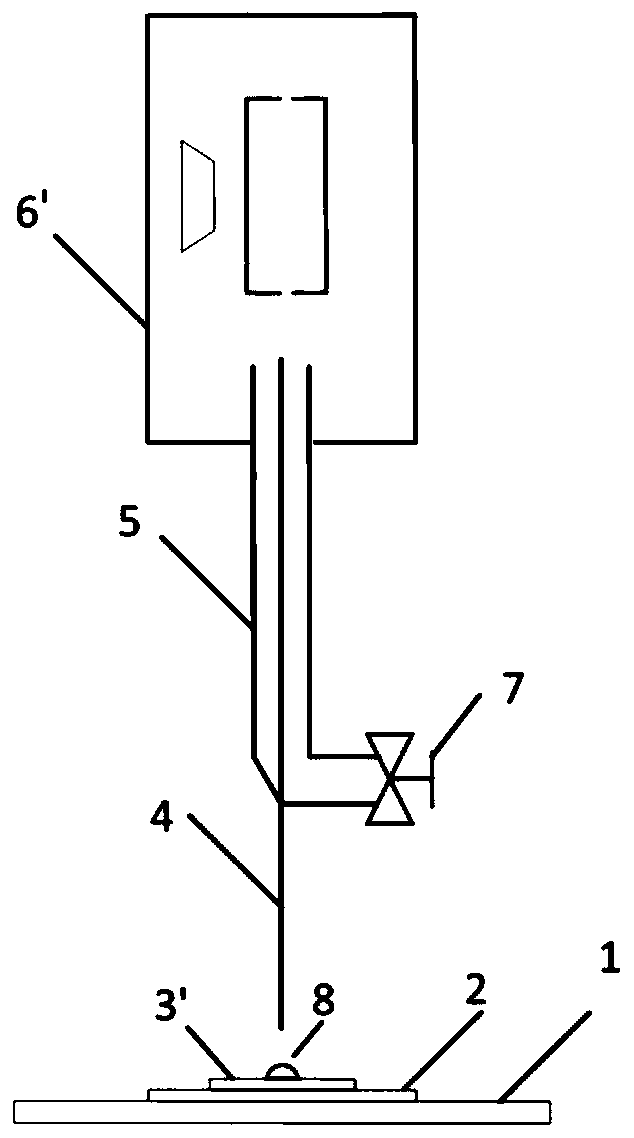

[0046] Such as figure 2 As shown, it includes a sample injection capillary 4, a carrier gas channel 5, a gas path valve 7, a lifting platform 1, an electrode 2, a sample plate 3', and a mass spectrometer cavity 6'.

[0047] One end of the sampling capillary 4 is used as the sampling end, the other end is placed in the cavity 6' of the mass spectrometer, the sampling capillary 4 passes through the carrier gas passage 5; the electrode 2 is placed under the sample plate 3, The droplet 8 to be tested is placed on the sample plate 3'; the electrode 2 and the sample plate 3' are placed together on the lift table 1; the lift table 1 can move up and down or three-dimensionally; the gas circuit valve 7 intermittently The capillary 4 is pulsed to contact the sample to be tested. When the droplet to be tested is transported to the end of the capillary 4, the gas valve 7 is opened instantaneously to promote the desolvation process of the electrospray, and finally the sample is detected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com