Compression unit of orbiting vane compressor

A technology of rotating blades and vanes, applied in the field of compression components, can solve the problems of deterioration of compressor performance, deterioration of sealing, deterioration of close contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

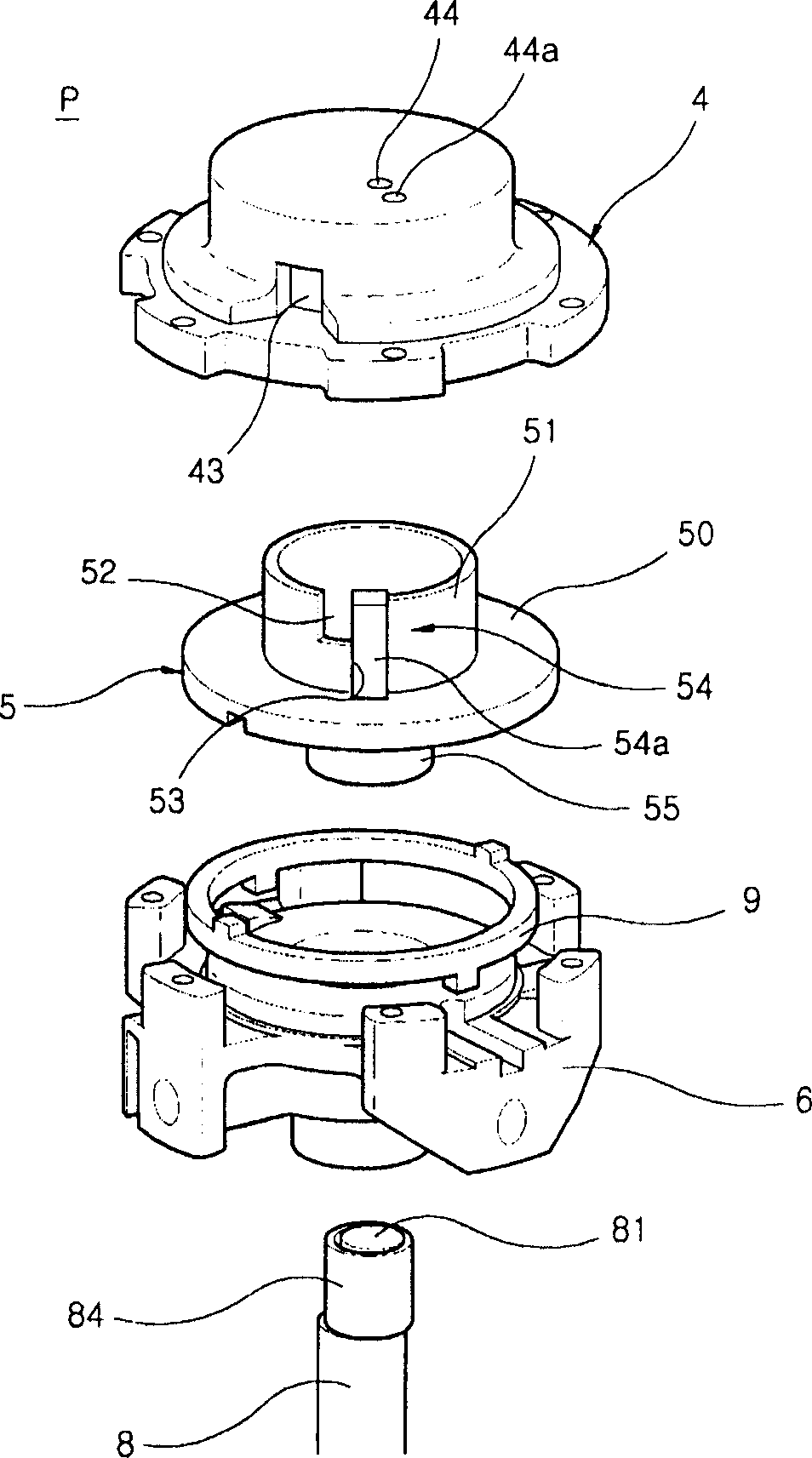

[0054] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

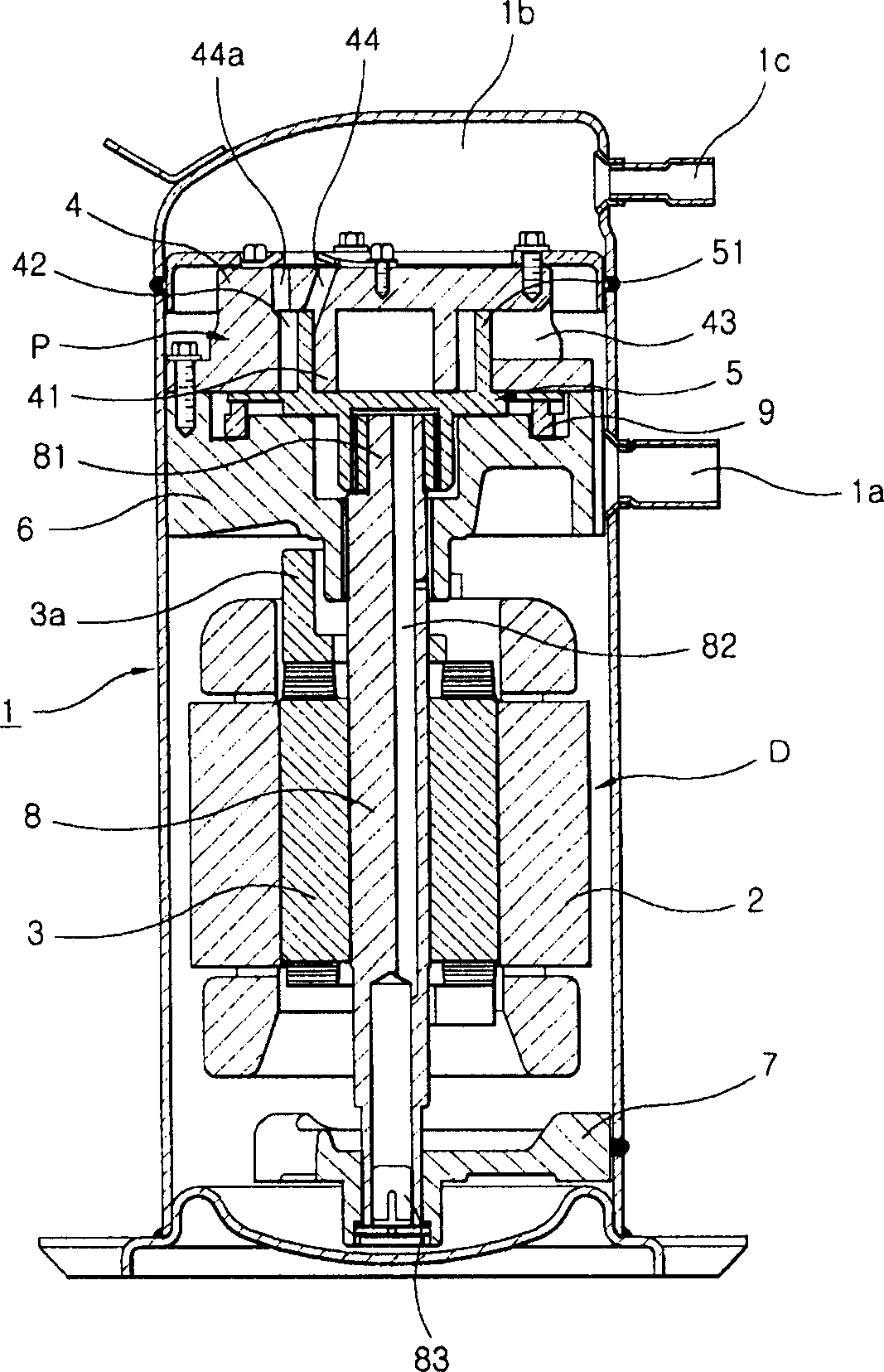

[0055] Figure 4 is a cross-sectional view illustrating a compression part of the rotary vane compressor according to the first preferred embodiment of the present invention.

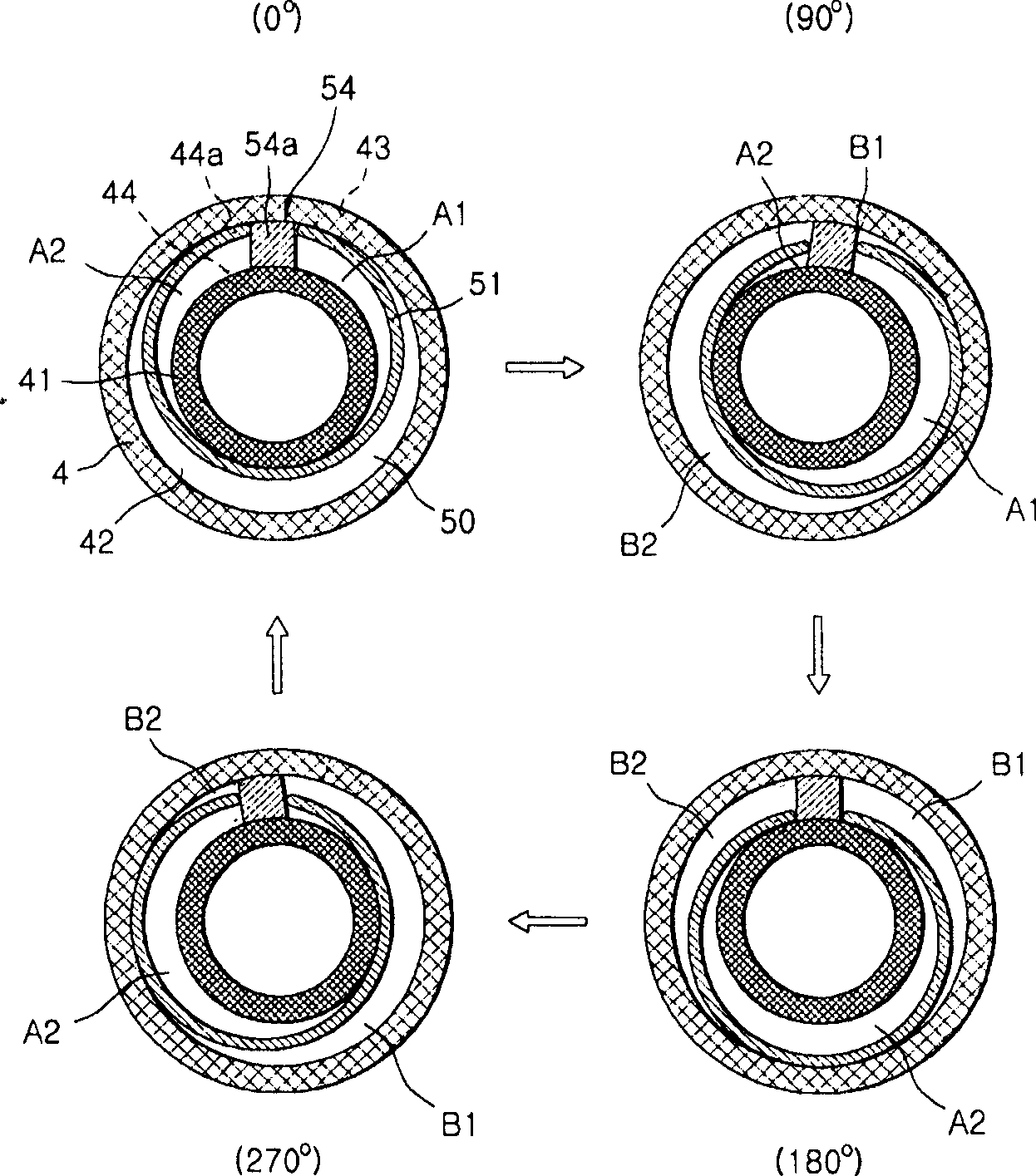

[0056] Such as Figure 4 As shown, the compression part of the rotary vane compressor according to the present invention comprises a sealing device 54 which, while tightly fitting in the opening formed in the circular vane 51, performs a linear reciprocating movement within the annular space defined in the cylinder. , in order to maintain the seal between a pair of pressurized chambers formed in the annular space 42 and at the same time maintain the seal between the suction chamber and the pressurized chamber also formed in the annular space 42 .

[0057] The sealing device 54 includes a linear slider 541 arranged between the first horizontal contact surface 411 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com