Long-path optical fiber-microfluidic chip sensor for detecting absorbance and refraction index

A microfluidic chip and refractive index technology, which is applied in the field of sensors, can solve the problems such as the difficulty of curved mirrors, and achieve the effects of real-time detection, small numerical aperture, and wide linear range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

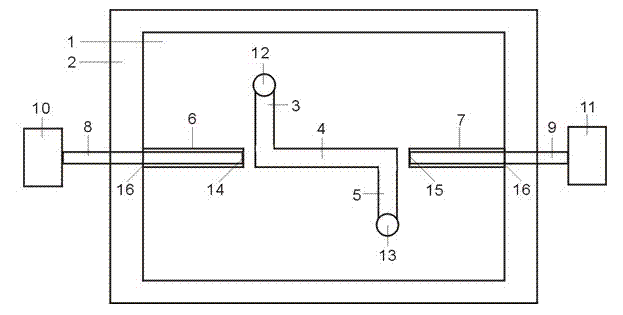

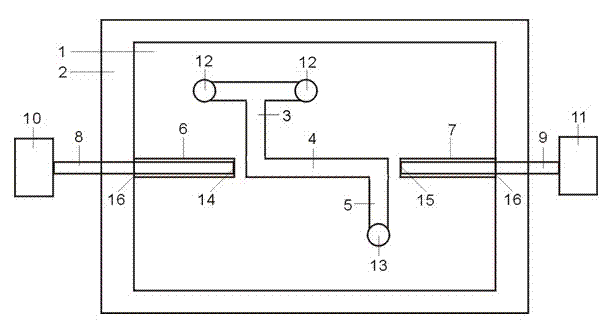

[0021] The structure and preparation method of the sensor of the present invention will be illustrated below by taking the transparent polymer polydimethylsiloxane (PDMS) to make a microfluidic chip and using a commercial multimode optical fiber (outer diameter 125 microns, core diameter 62.5 microns) as an example . It should be noted that this embodiment is not a limitation to the technical solution of the present invention, and the present invention can also use other transparent materials to make microfluidic chips and use other optical fibers; the dimensional values related to each channel and optical fiber are only for illustrating the present invention For convenience and use, the present invention is not limited to the specific numerical values listed below.

[0022] Specifically, in this embodiment, the microfluidic chip can be prepared by using an SU-8 male mold and PDMS with a refractive index of about 1.41. In the sensor of the present invention, the role of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com