Patents

Literature

43results about How to "Less surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

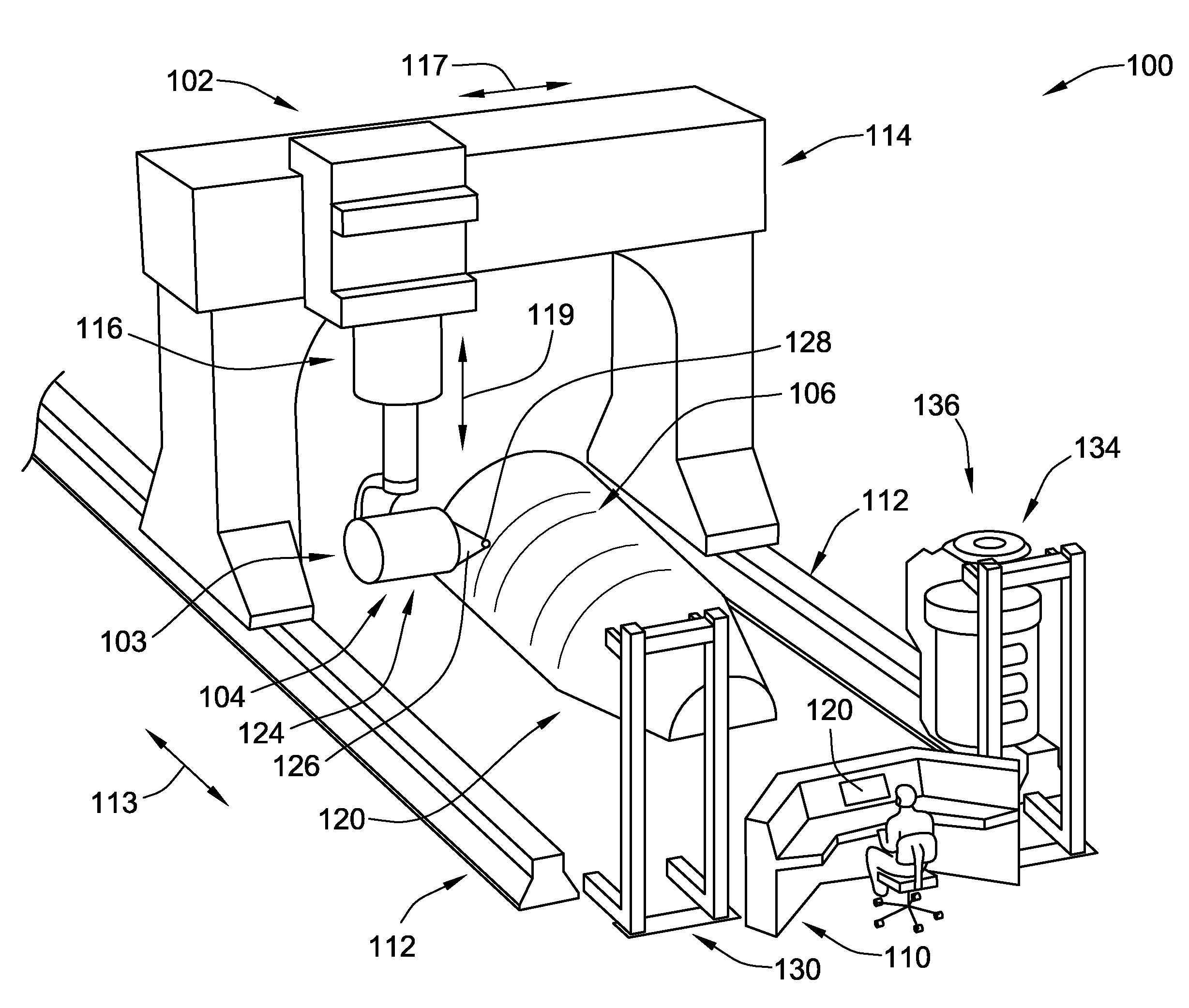

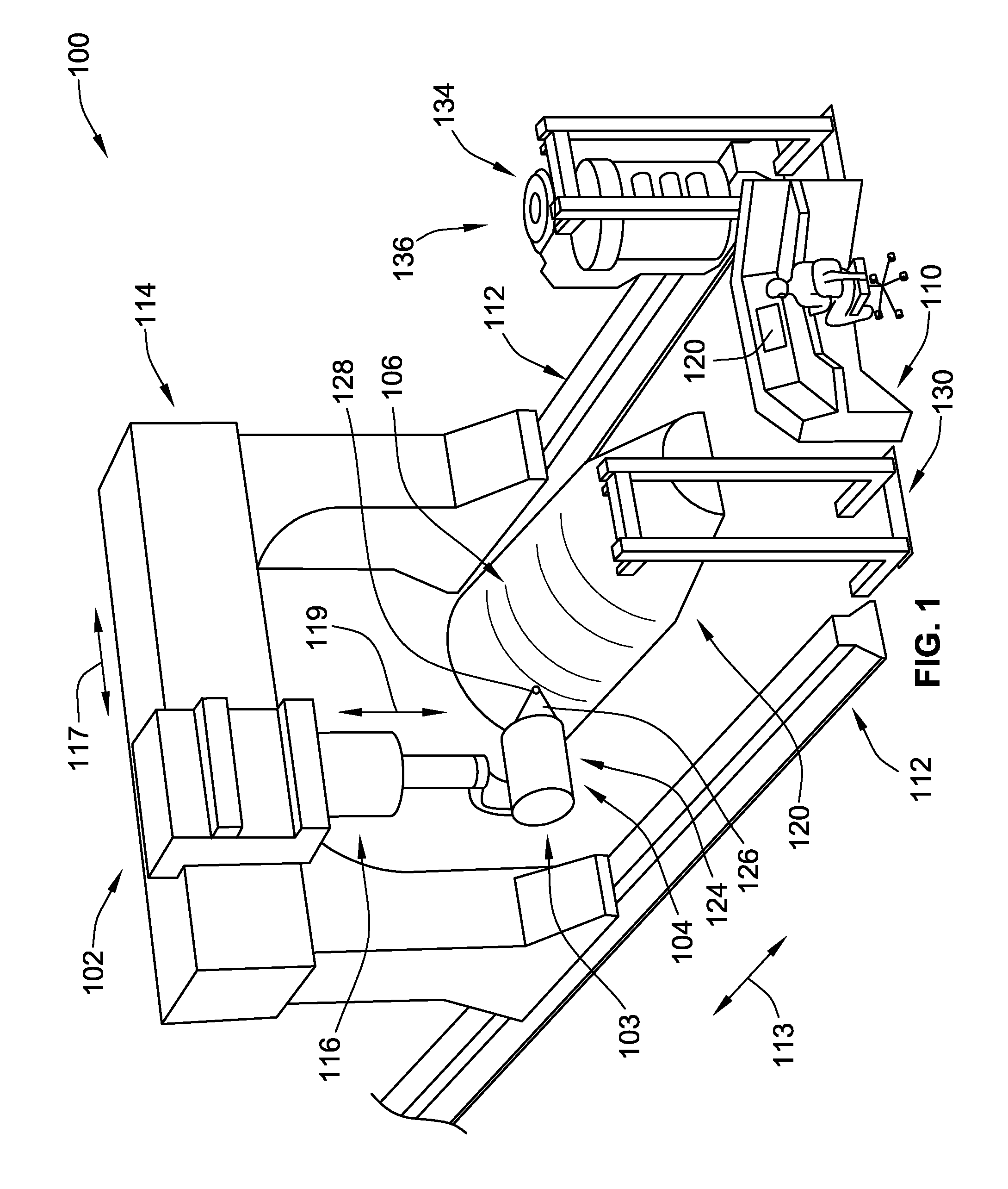

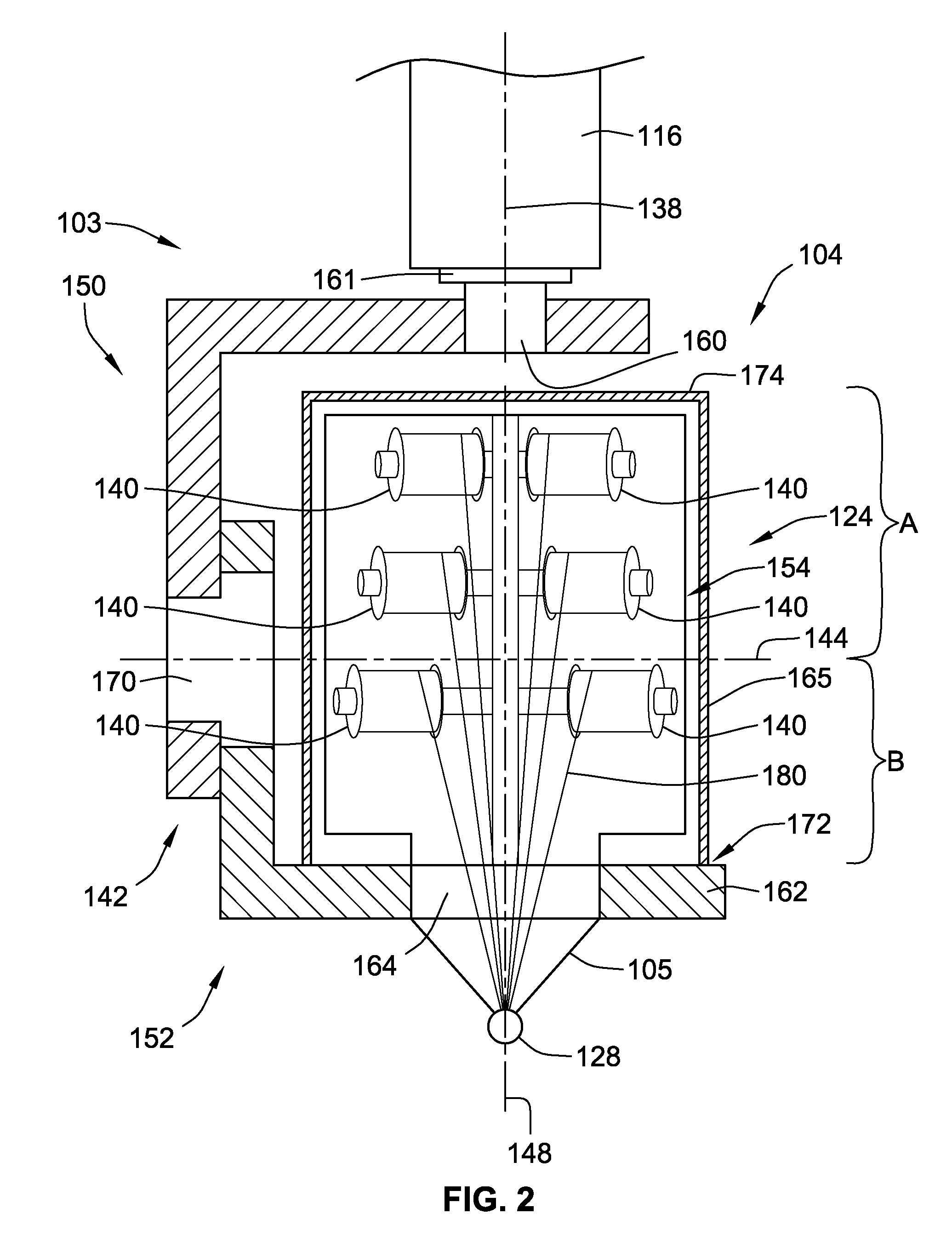

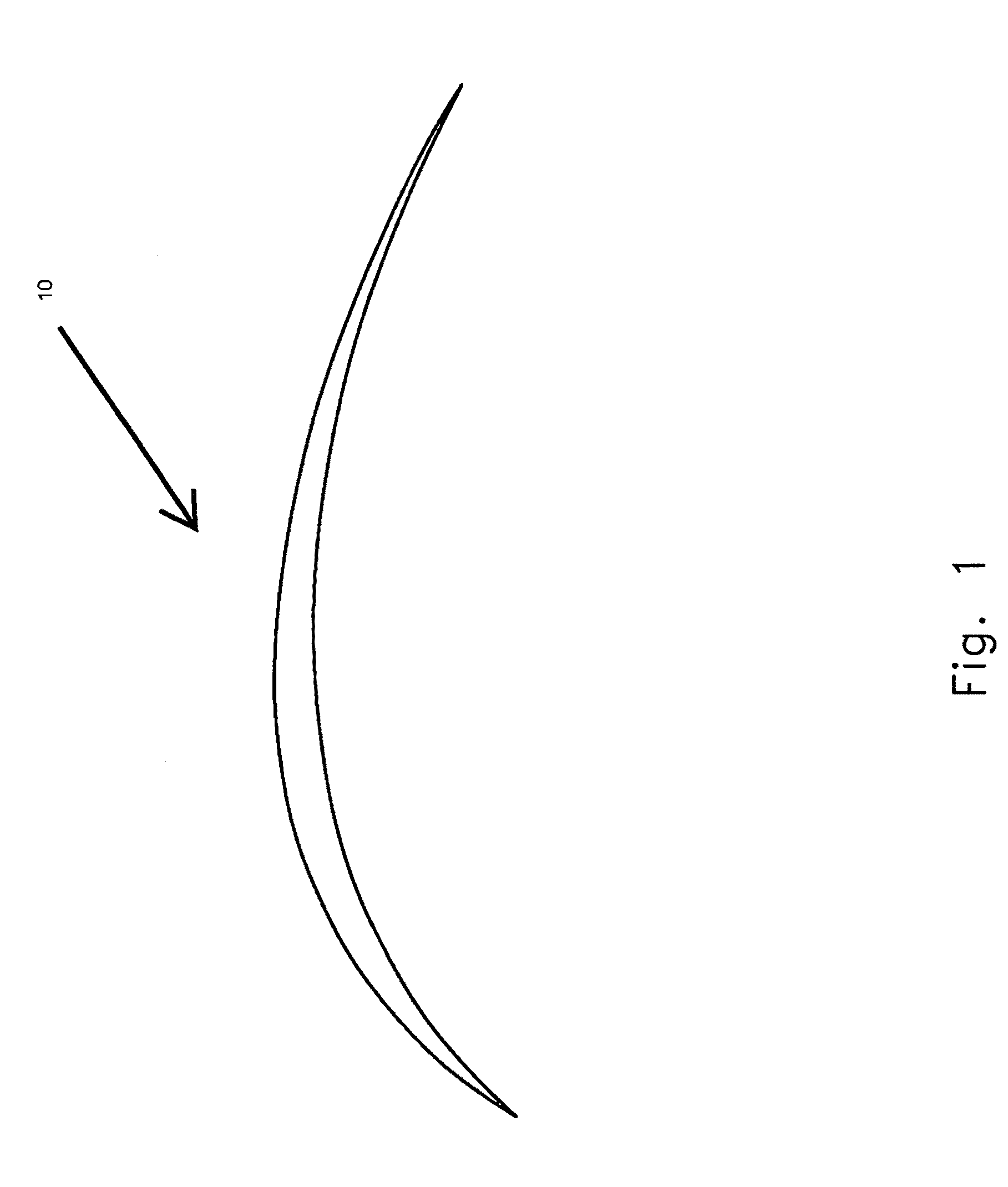

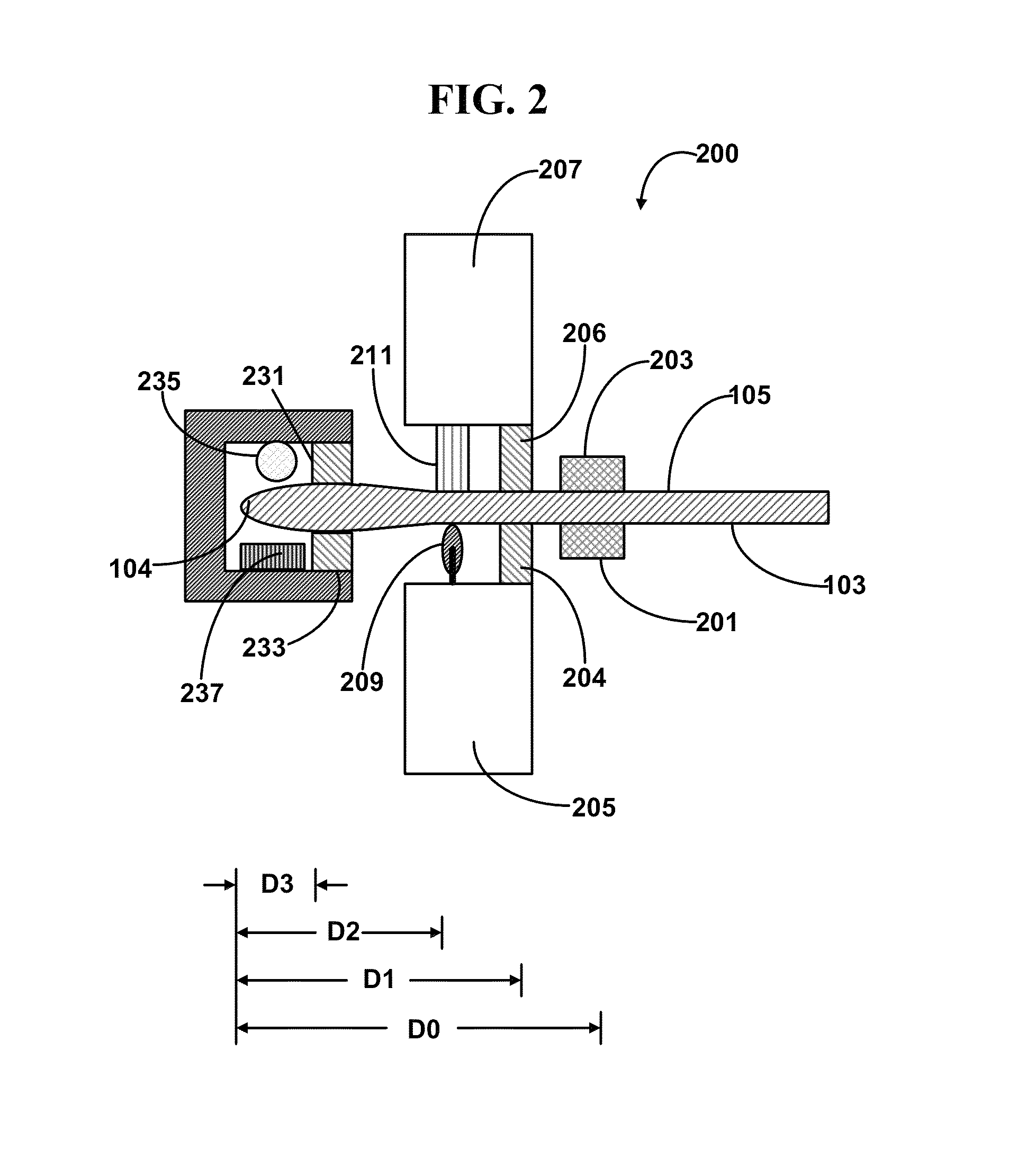

Fiber delivery apparatus and system having a creel and fiber placement head sans fiber redirect

A fiber delivery apparatus having a creel assembly and a fiber placement head is provided. A plurality of fiber spools are stored in the creel assembly. The tow paths from the spools to the fiber placement head are substantially fixed such that movements orienting the fiber placement head relative to a tool are simultaneously applied to the fiber spools as well. As such, the length and orientation of the tow paths between the spools and the fiber placement head are constant.

Owner:INGERSOLL MACHINE TOOLS

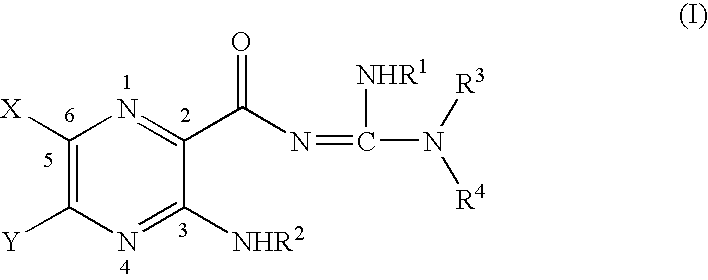

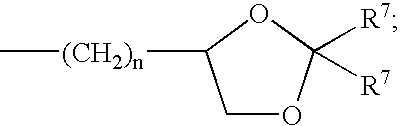

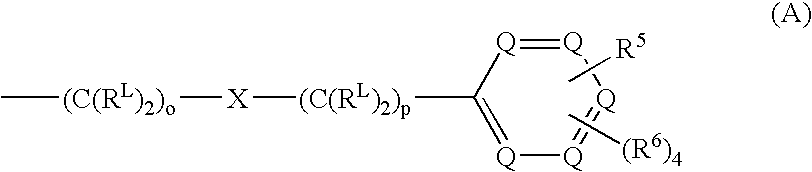

New capped pyrazinoylguanidine sodium channel blockers

InactiveUS20070032509A1Less surfaceLess reversibleSenses disorderNervous disorderChemistryTreatment use

Owner:PARION SCI DURHAM NC

Water repellent compositions for wood preservatives

InactiveUS7264886B2Improve permeabilityImprove waterproof performanceFireproof paintsWax coatingsWaxWater based

Water-based wax emulsions, optionally for use in conjunction with alkaline copper and / or quaternary ammonium based preservatives systems, are described. These emulsions are comprised of natural or synthetic wax, nonionic surfactants having HL B values greater than 11, anionic surfactants, and water. Certain emulsion compositions as described in this specification posses the unique property of maintaining emulsion stability in wood preservatives during extended use in typical wood treatment processes. Water-repellant wood treated with the wax emulsions are described. A method of treating wood, comprising providing wood and treating the wood with the wax emulsion under conditions effective to increase its water repellency is also disclosed.

Owner:VIANCE

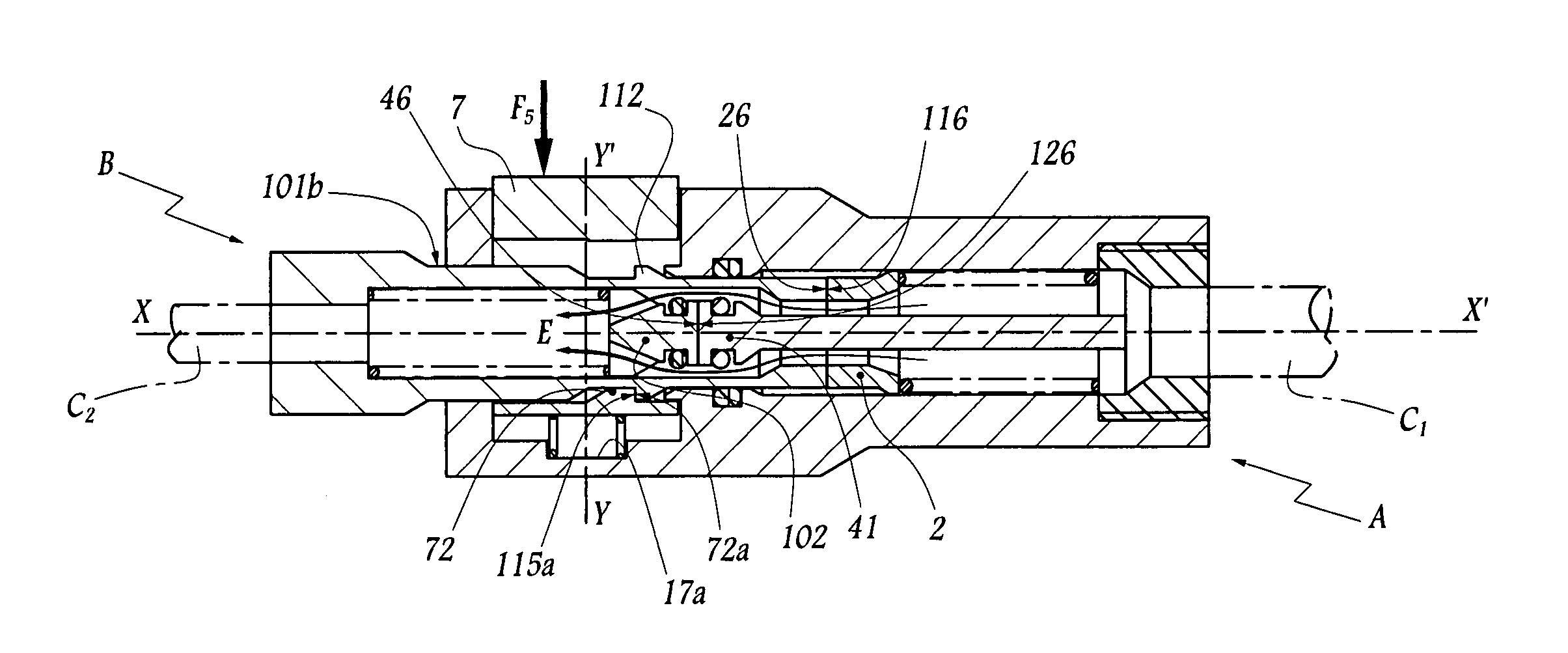

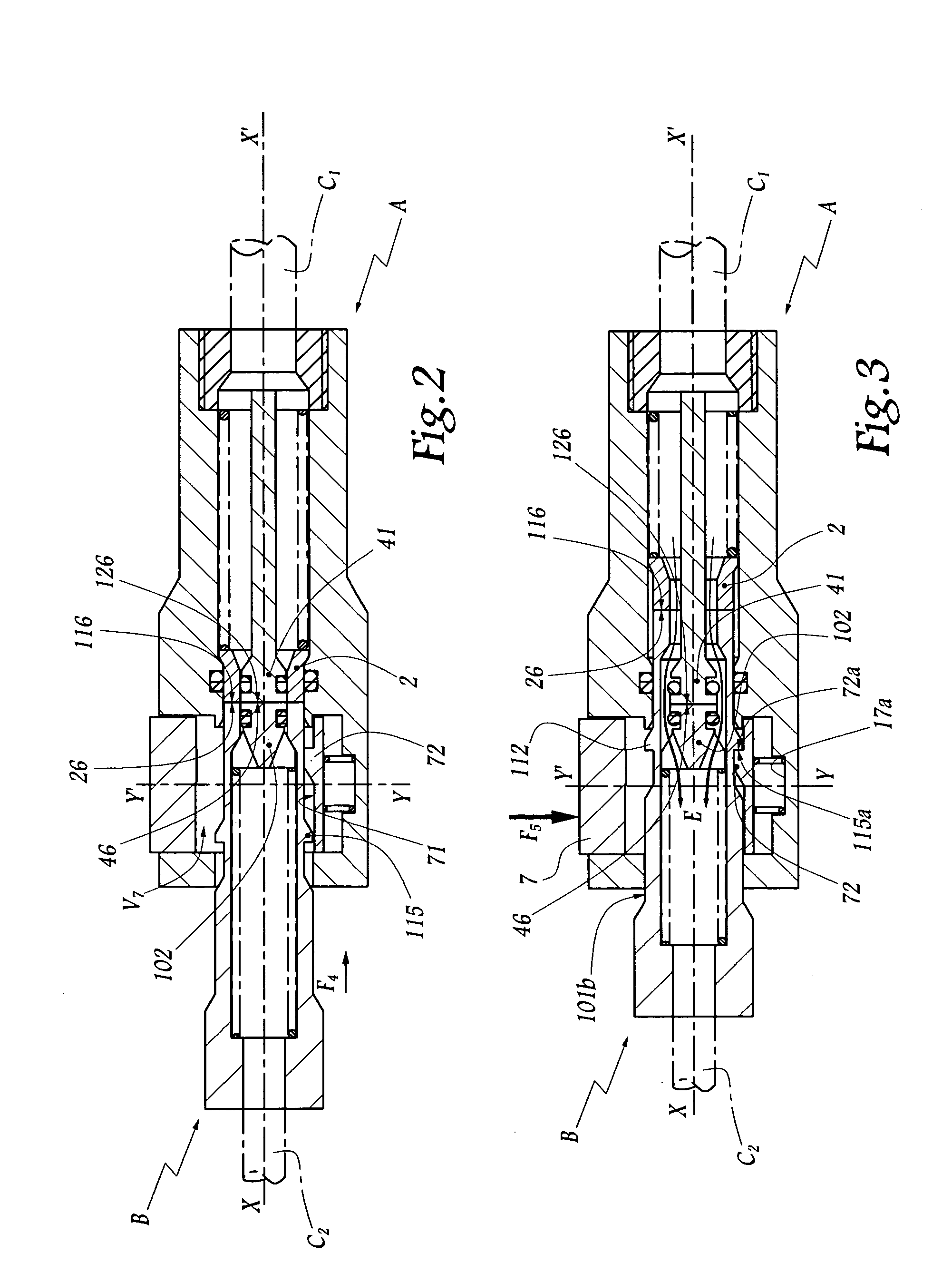

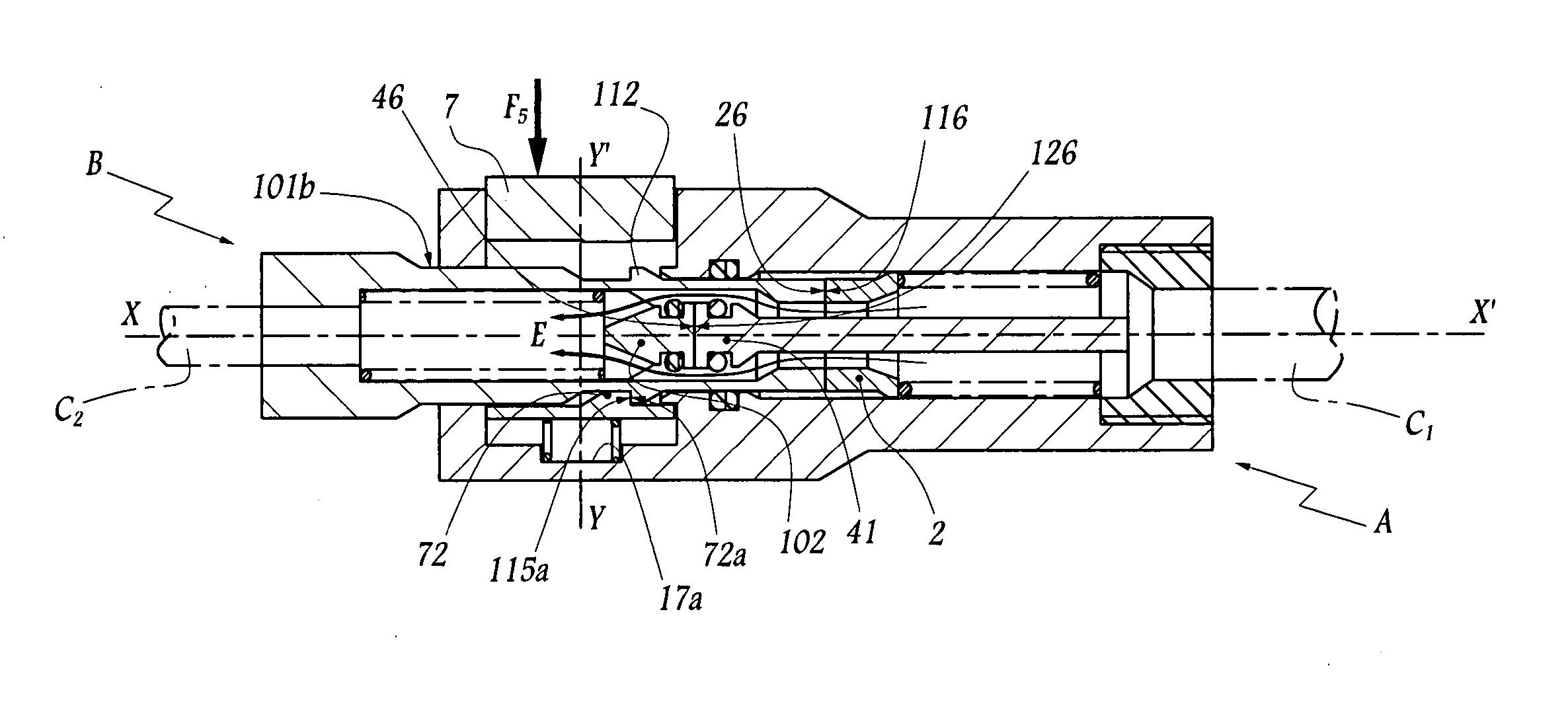

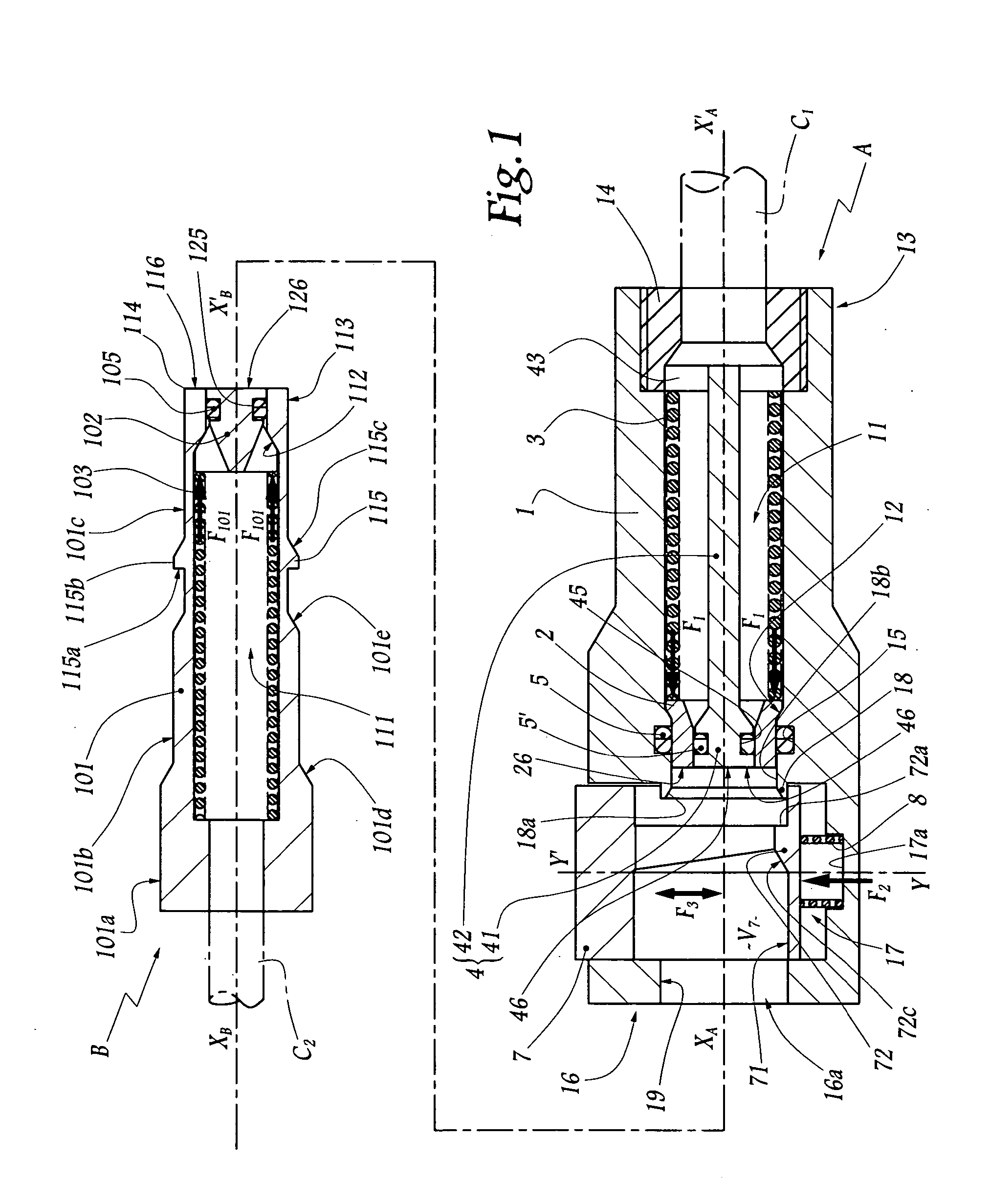

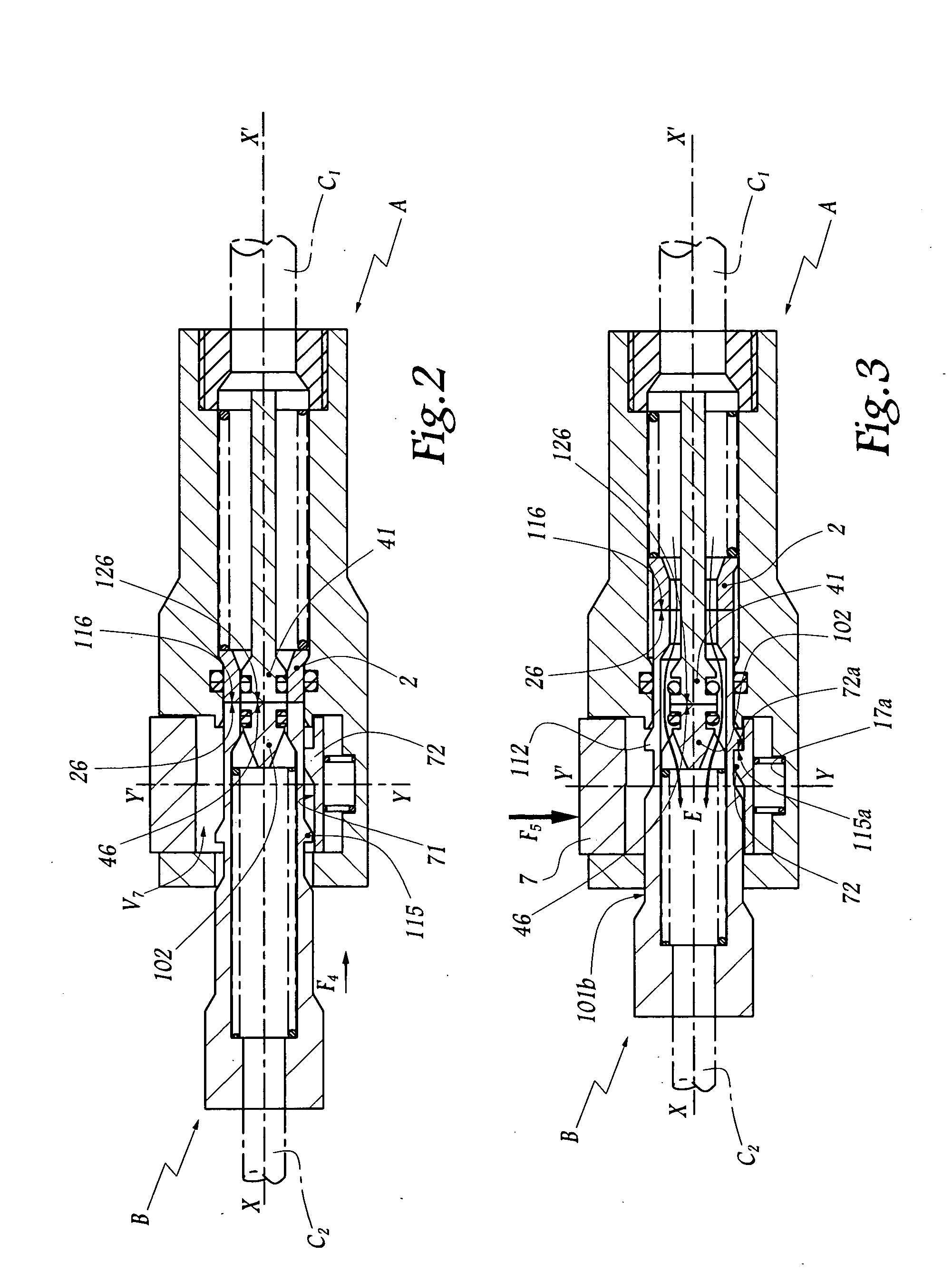

Quick connection for removably joining two pipes and use of such a connection

ActiveUS7044161B2Minimized dimensionLittle riskCouplingsThin material handlingEngineeringMechanical engineering

A quick connect coupling including male and female elements that are adapted to fit axially in each other and each includes a valve that is displaced to an open position by engagement by a fixed pusher part of each element when they are being fitted together. The female element is provided with a locking member in which a part of the male element is received and which is reciprocally movable in a radial direction with respect to an axis of fit of the elements between two positions in which the locking member respectively allows or opposes the separation of the male and female elements and wherein the engaging surfaces of the valves and pusher parts is such that no open volumes or voids are created therein in which a liquid may collect during assembly or disassembly of the male and female elements.

Owner:STAUBLI FAVERGES SA

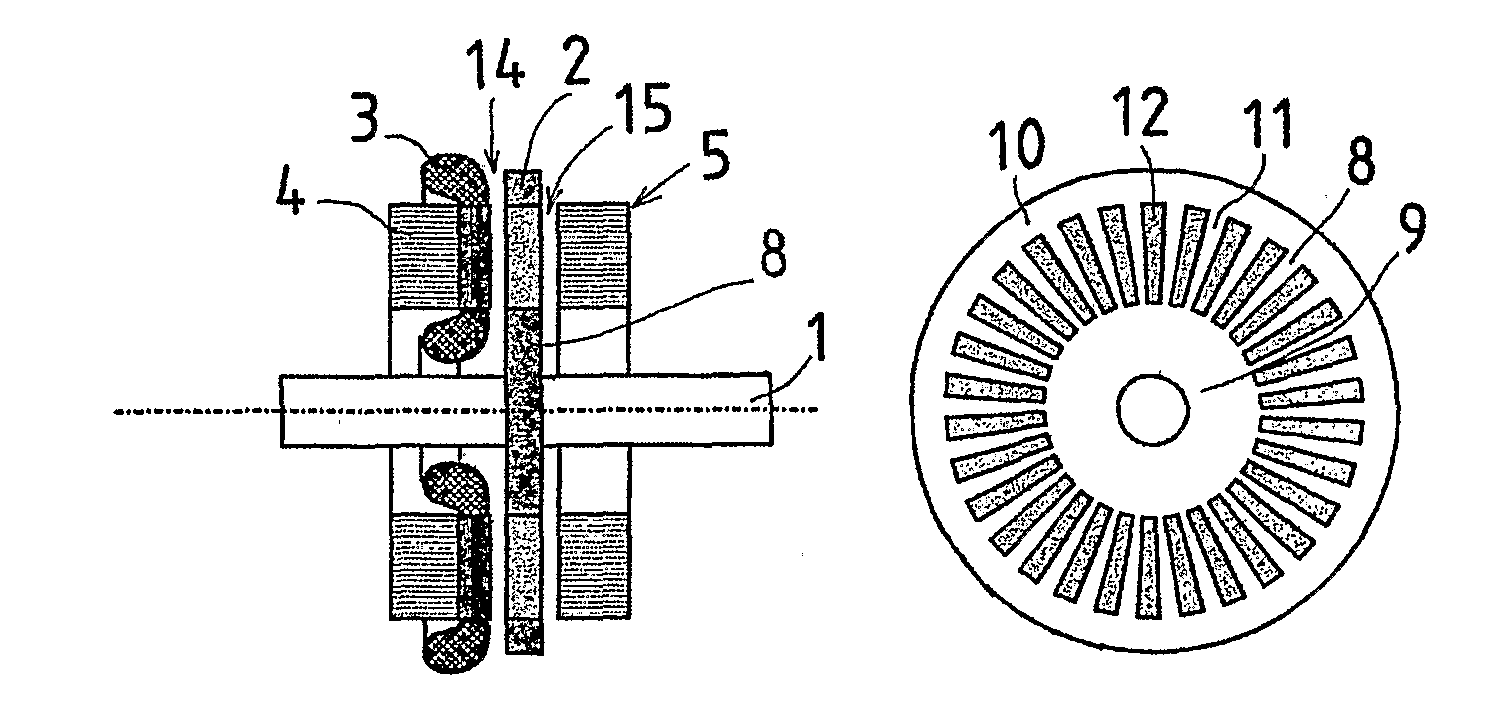

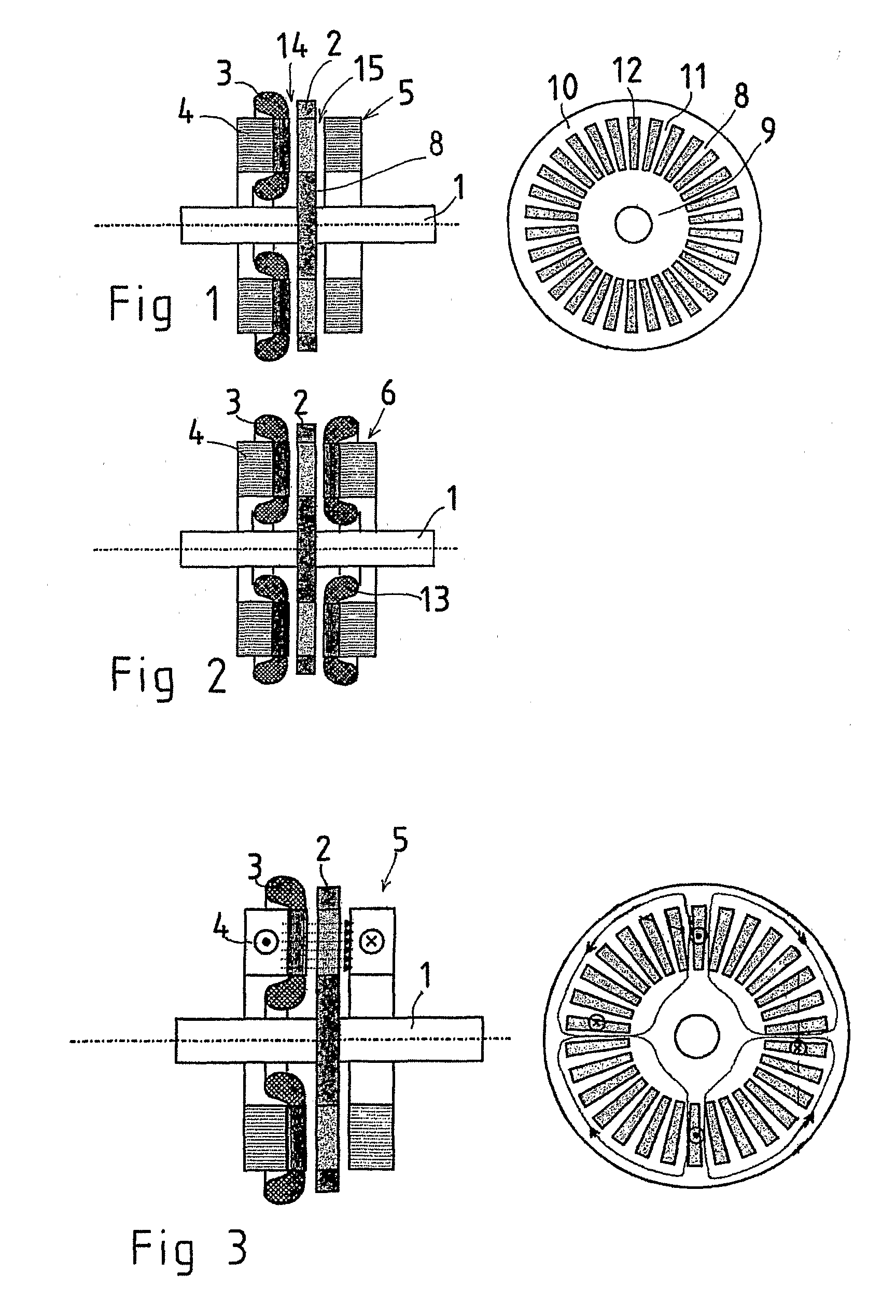

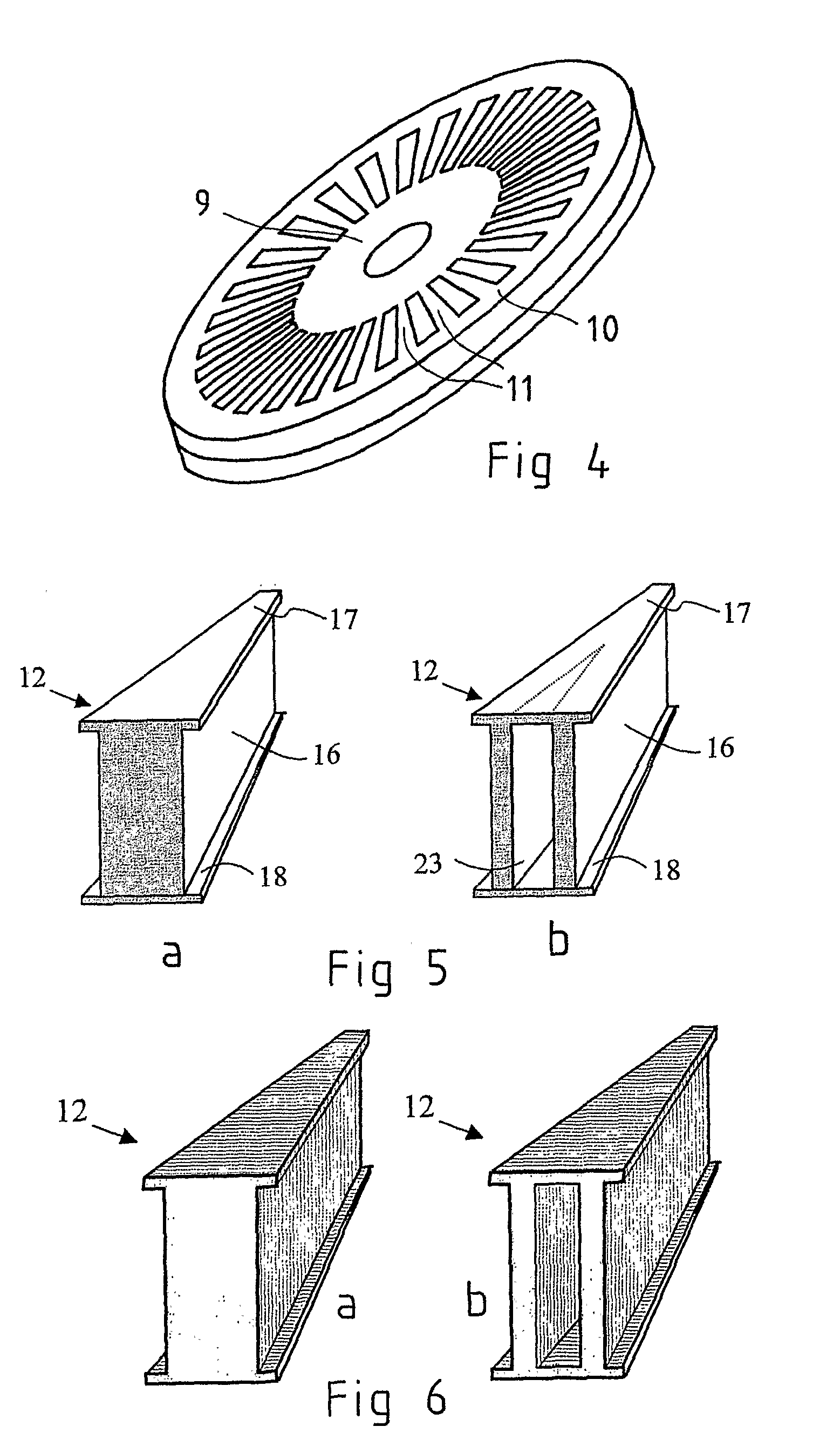

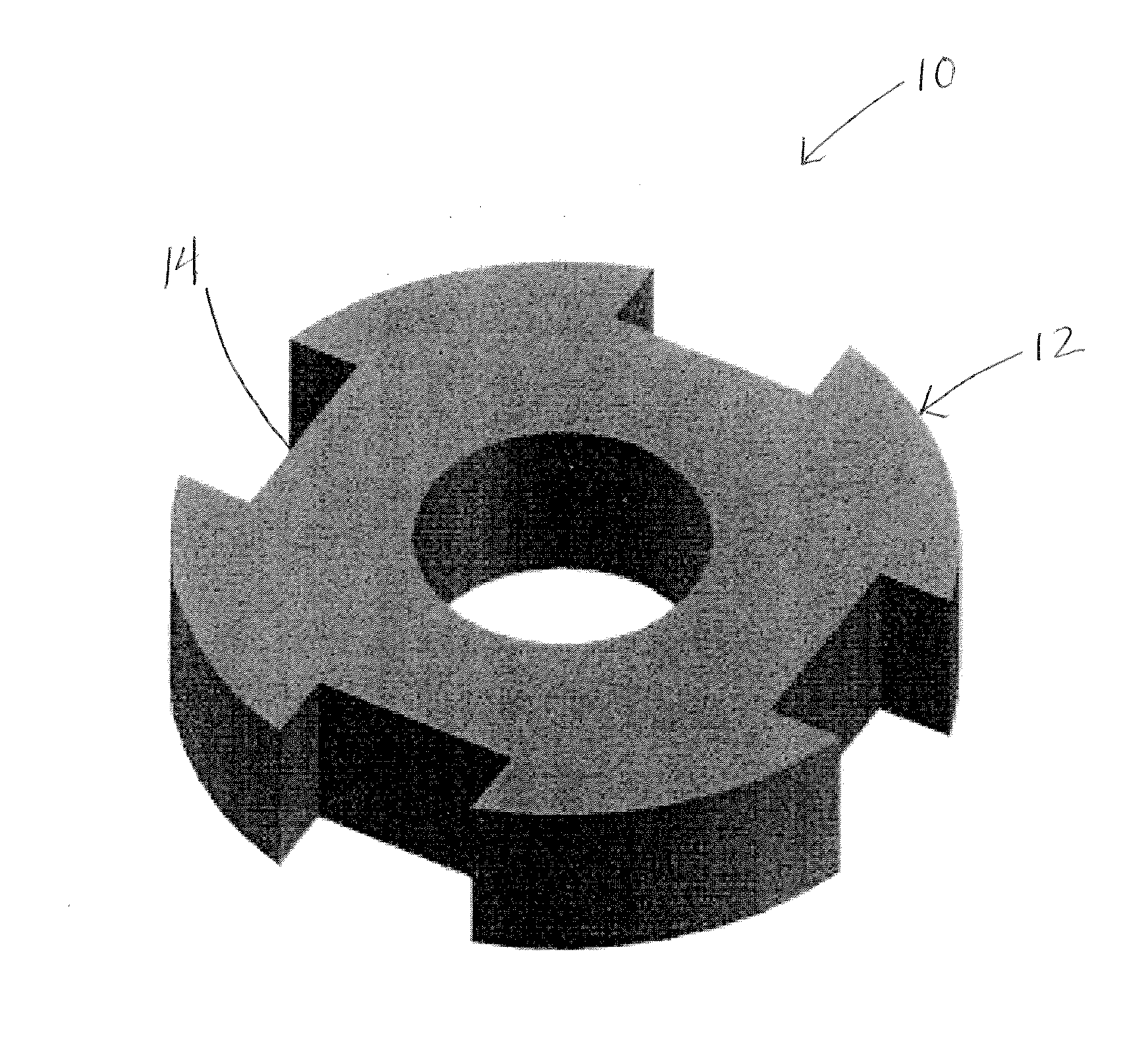

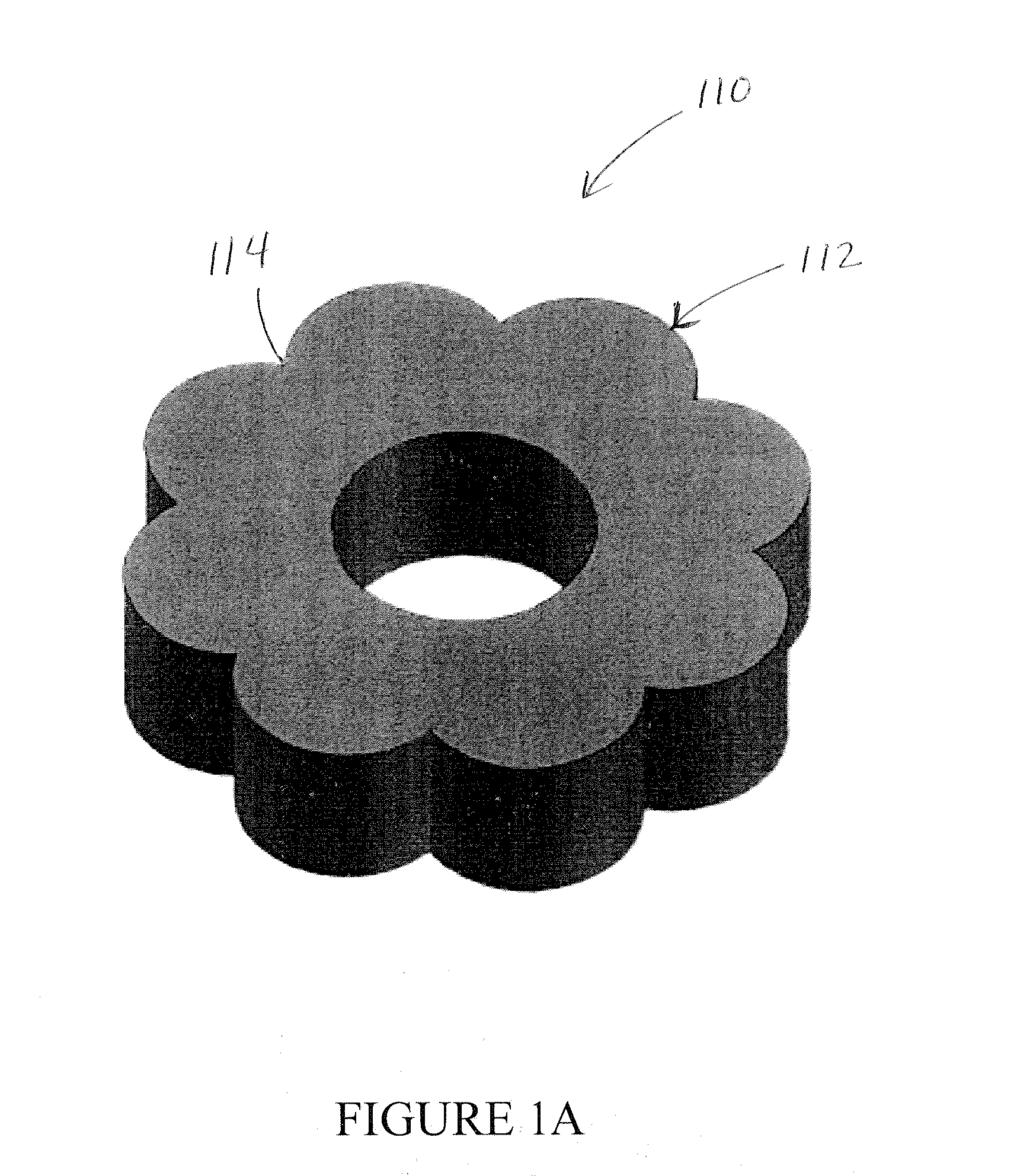

Axial Flux Induction Electric Machine

InactiveUS20080001488A1Easy to with power toolIncrease speedSynchronous generatorsWindingsAxial fluxWork hardening

The invention relates to an axial flux induction electrical machine comprising a frame, a shaft (1) bearing-mounted to the frame, a disc-like rotor (2) supported to the shaft, a stator (4) comprising a stator winding (3) and supported by the frame on the first side of the rotor in axial direction. The disc-like rotor (2) comprises a non-ferromagnetic rotor frame (8) fabricated of a material with high electrical conductivity and comprising a uniform inner periphery (9) and an outer periphery (10) and conductor bars (11) fabricated of the same material and galvanically connecting the peripheries (11), the conductor bars together with the inner and outer peripheries forming in addition to the rotor frame also the cage winding of the rotor. In addition, between the inner periphery and the outer periphery there is a plurality of ferromagnetic pieces (12) extending through the frame plate and being spaced apart from each other at an appropriate distance so that the radial conductor bars are appropriately located between the pieces. According to the invention, the disc-like rotor frame (8) comprises at least one circular plate machined of work-hardened metal sheet.

Owner:AXCO MOTORS OY

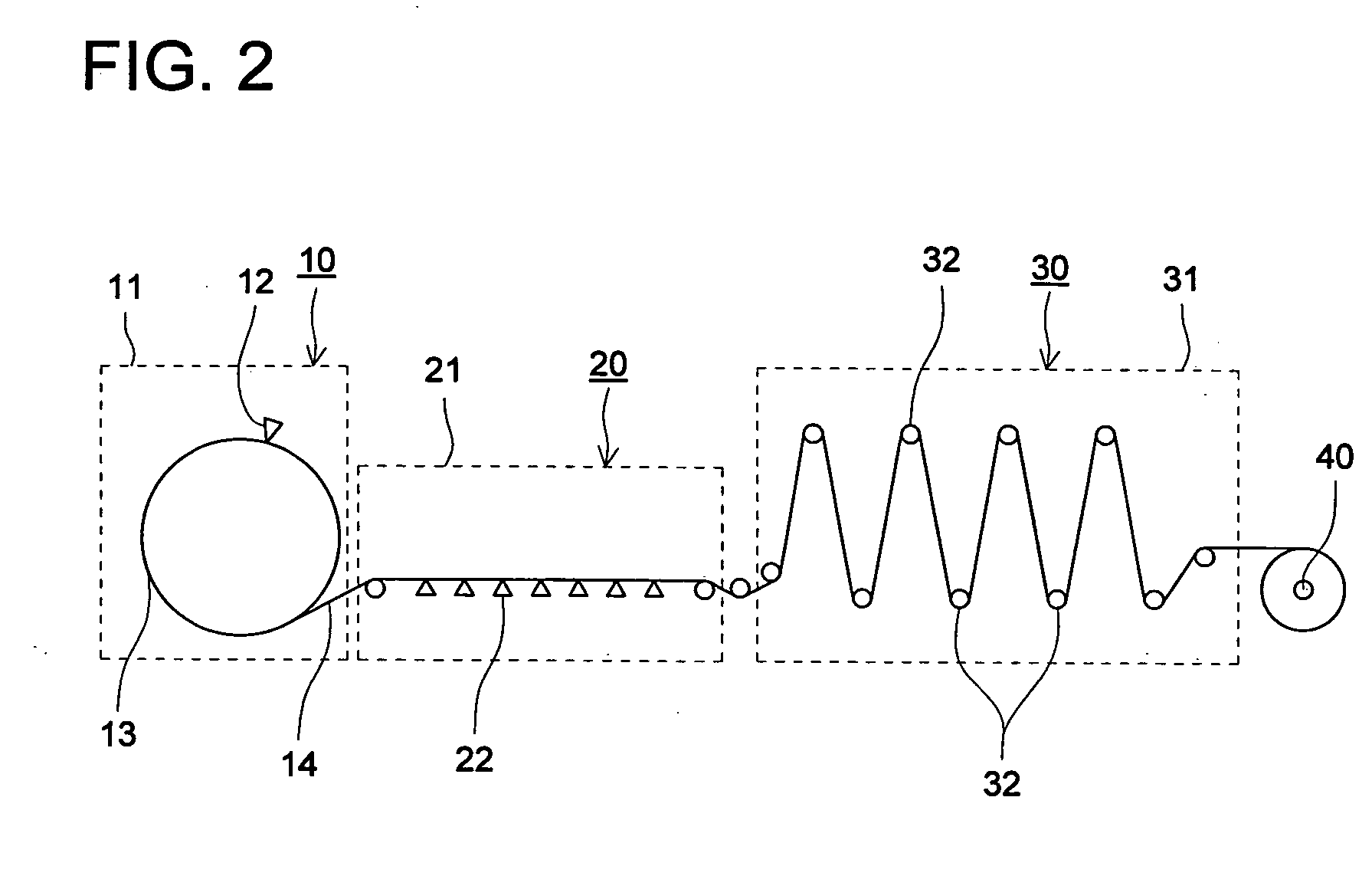

Anode and battery

ActiveUS20050191547A1Improving impedanceVariation in characteristicElectrode thermal treatmentFinal product manufactureLithium carbonateVapor phase

Provided are an anode capable of preventing an increase in impedance and variations in characteristics and a battery using the anode. An anode active material layer includes at least one kind selected from the group consisting of simple substances, alloys and compounds of silicon and the like capable of forming an alloy with Li. The anode active material layer is formed by a vapor-phase deposition method or the like, and is alloyed with an anode current collector. A coating including lithium carbonate is formed on at least a part of a surface of the anode current collector. Thereby, an increase in impedance can be prevented. Moreover, the anode is less subject to an influence by a difference in a handling environment or storage conditions, so variations in impedance can be prevented.

Owner:MURATA MFG CO LTD

Cellulose ester film and its manufacturing method, optical film, polarizing plate and liquid crystal display

ActiveUS20050271834A1Increase productivityGood storage stabilityLiquid crystal compositionsPolarising elementsPolarizerLiquid-crystal display

Disclosed is a cellulose ester film containing cellulose ester and microparticles having an average primary particle diameter of from 0.1 to 1.0 μm, wherein a relative standard deviation of a primary particle diameter of the microparticles is from 1 to 20%, and wherein the cellulose ester film has a surface with a peak density of from 1,000 to 8,000 (1 / mm2).

Owner:KONICA MINOLTA OPTO

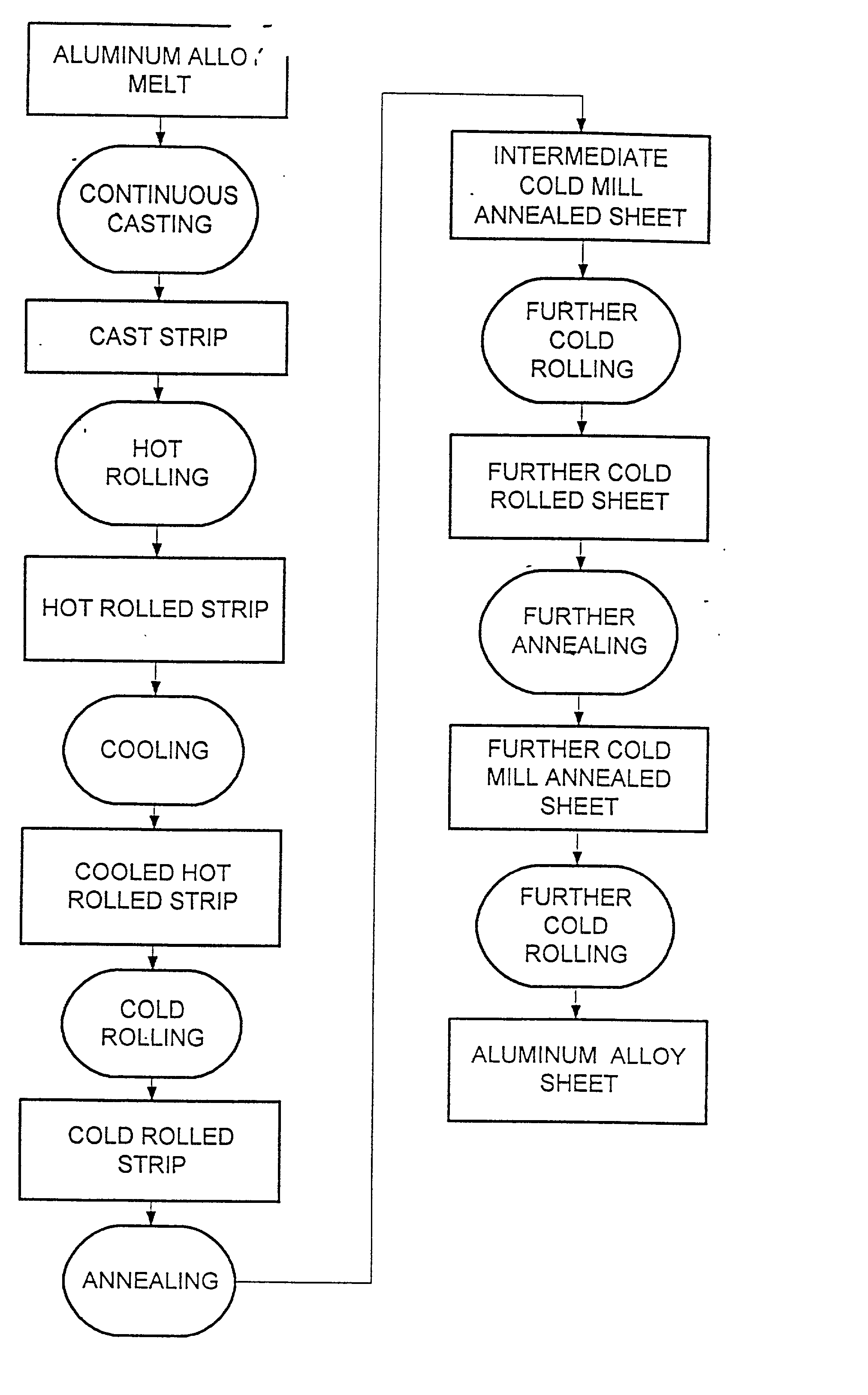

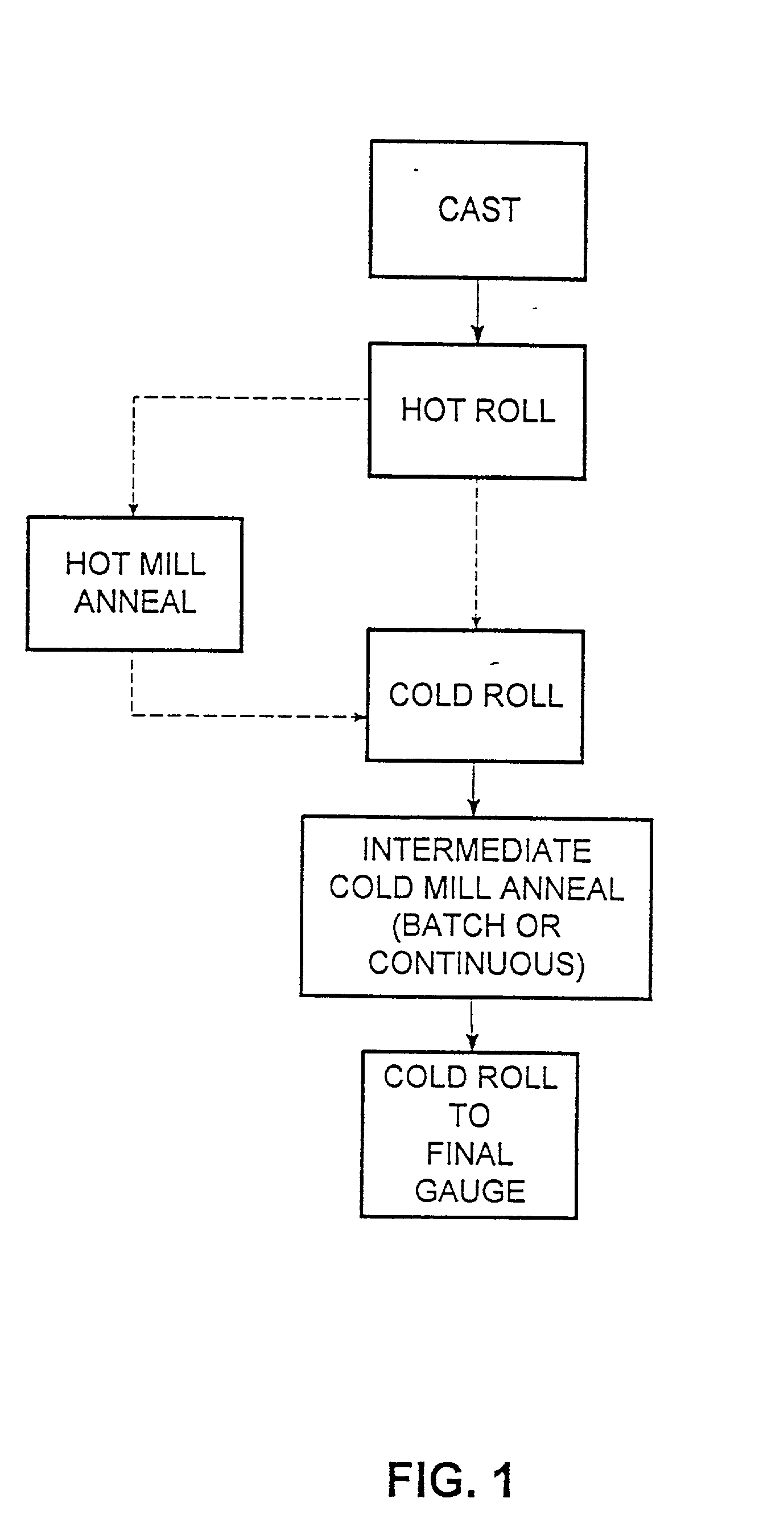

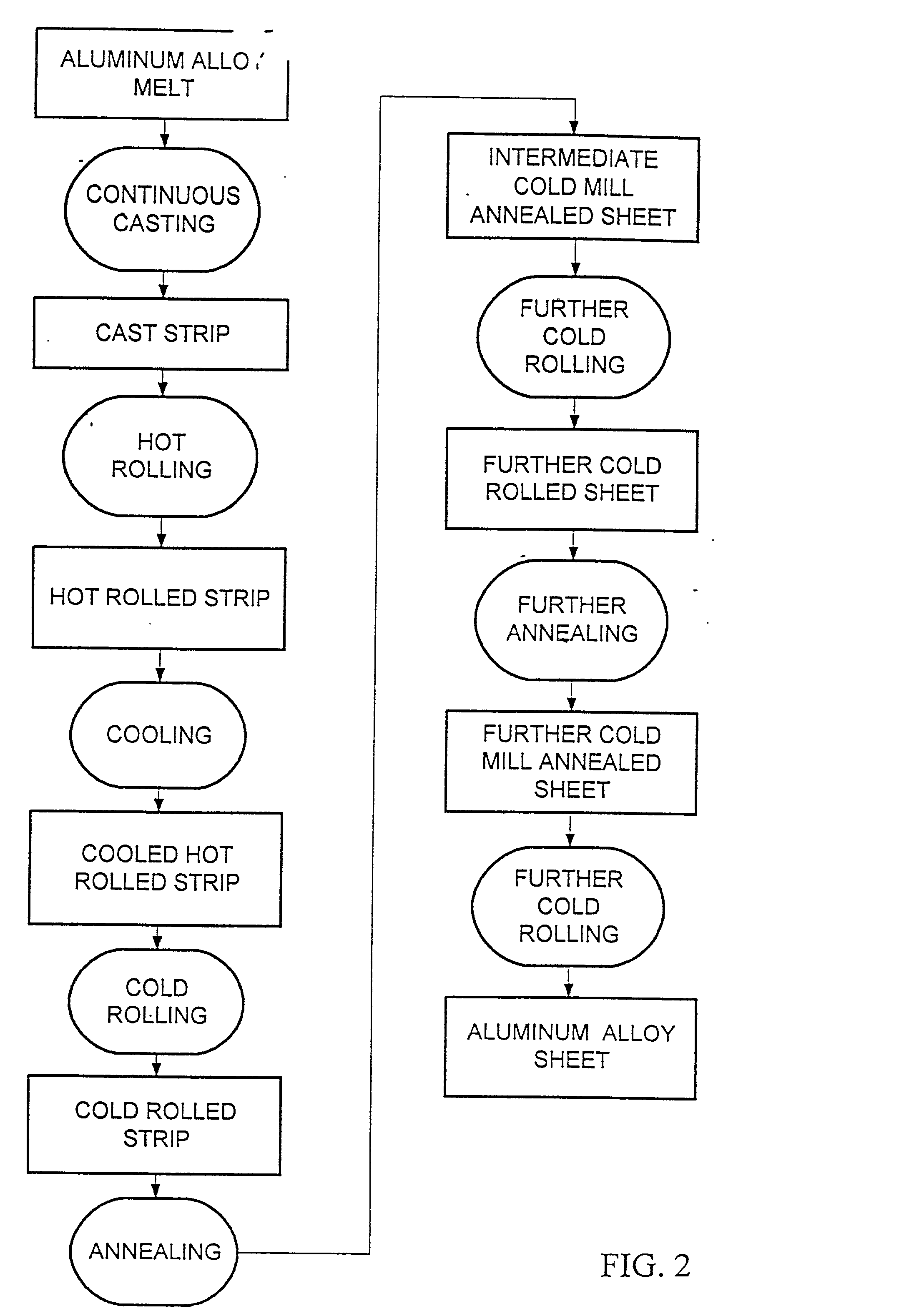

Method for making an improved aluminum alloy sheet product

InactiveUS20020043311A1High reductions in gaugeGreater hot mill and cold mill reductionsUltimate tensile strengthAluminium alloy

An aluminum alloy sheet and a method for producing an aluminum alloy sheet. The aluminum alloy sheet is useful for forming into drawn and ironed container bodies. The sheet preferably has an after-bake yield strength of at least about 37 ksi and an elongation of at least about 2 percent. Preferably, the sheet also has earing of less than about 2 percent.

Owner:NICHOLS ALUMINUM - GOLDEN

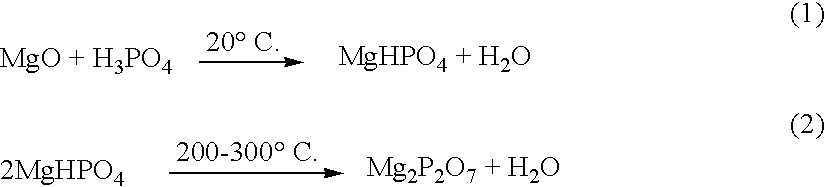

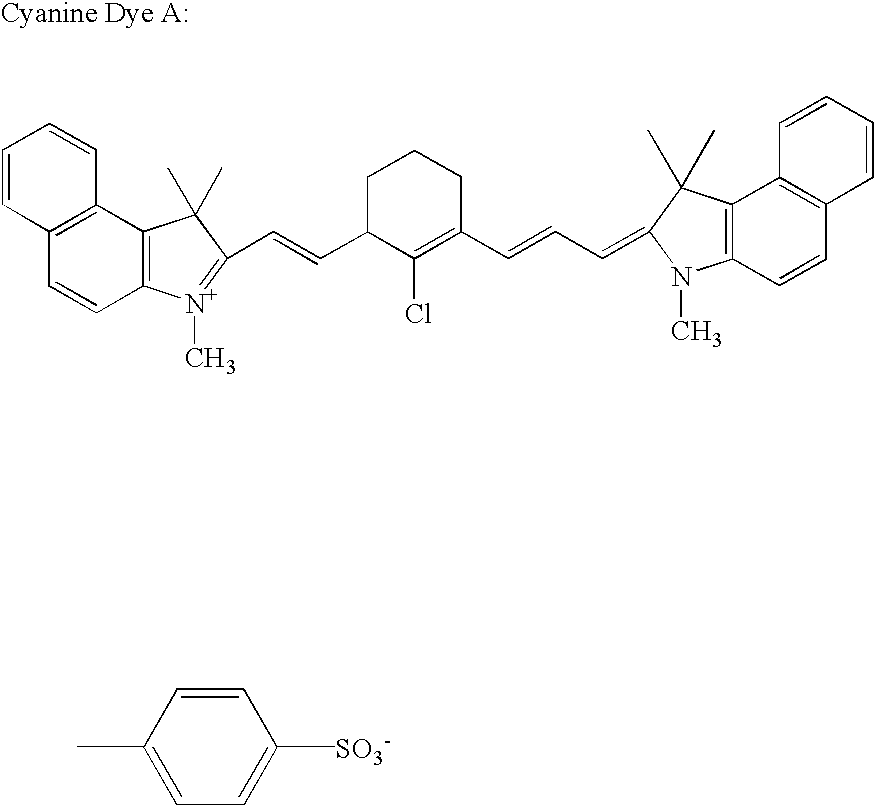

Lithographic printing plate support and production method thereof

InactiveUS20040154488A1High sensitivityImprove the immunitySemiconductor/solid-state device manufacturingPlate printingOxidePorous layer

A lithographic printing plate support comprising a substrate having thereon a porous layer comprising metal oxide particles bound by a compound containing a metal atom and a phosphorus atom.

Owner:FUJIFILM CORP +1

Method and device for hardening profiles

InactiveUS20110011499A1Hardness distribution be easilyImprove stabilityFurnace typesIncreasing energy efficiencyHardnessMaterials science

The invention relates to a method for producing hardened profiles, in particular hardened open profiles, wherein the component is at least partly heated to above the austenitizing temperature of the base material and after heating the component is cooled at a rate above the critical hardening rate, the energy necessary for the heating being introduced at least partly by induction, wherein free edges are provided in the component to adjust a temperature or hardness gradient over the cross section of the component, the size, type and extension of the edges being set for a desired degree of hardness and / or hardness gradient.

Owner:VOESTALPINE KREMS

Water repellent compositions for wood preservatives

InactiveUS20050132926A1Improve permeabilityImprove waterproof performanceFireproof paintsWax coatingsWaxWater based

Water-based wax emulsions, optionally for use in conjunction with alkaline copper and / or quaternary ammonium based preservatives systems, are described. These emulsions are comprised of natural or synthetic wax, nonionic surfactants having HL B values greater than 11, anionic surfactants, and water. Certain emulsion compositions as described in this specification posses the unique property of maintaining emulsion stability in wood preservatives during extended use in typical wood treatment processes. Water-repellant wood treated with the wax emulsions are described. A method of treating wood, comprising providing wood and treating the wood with the wax emulsion under conditions effective to increase its water repellency is also disclosed.

Owner:CHEM SPECIALTIES

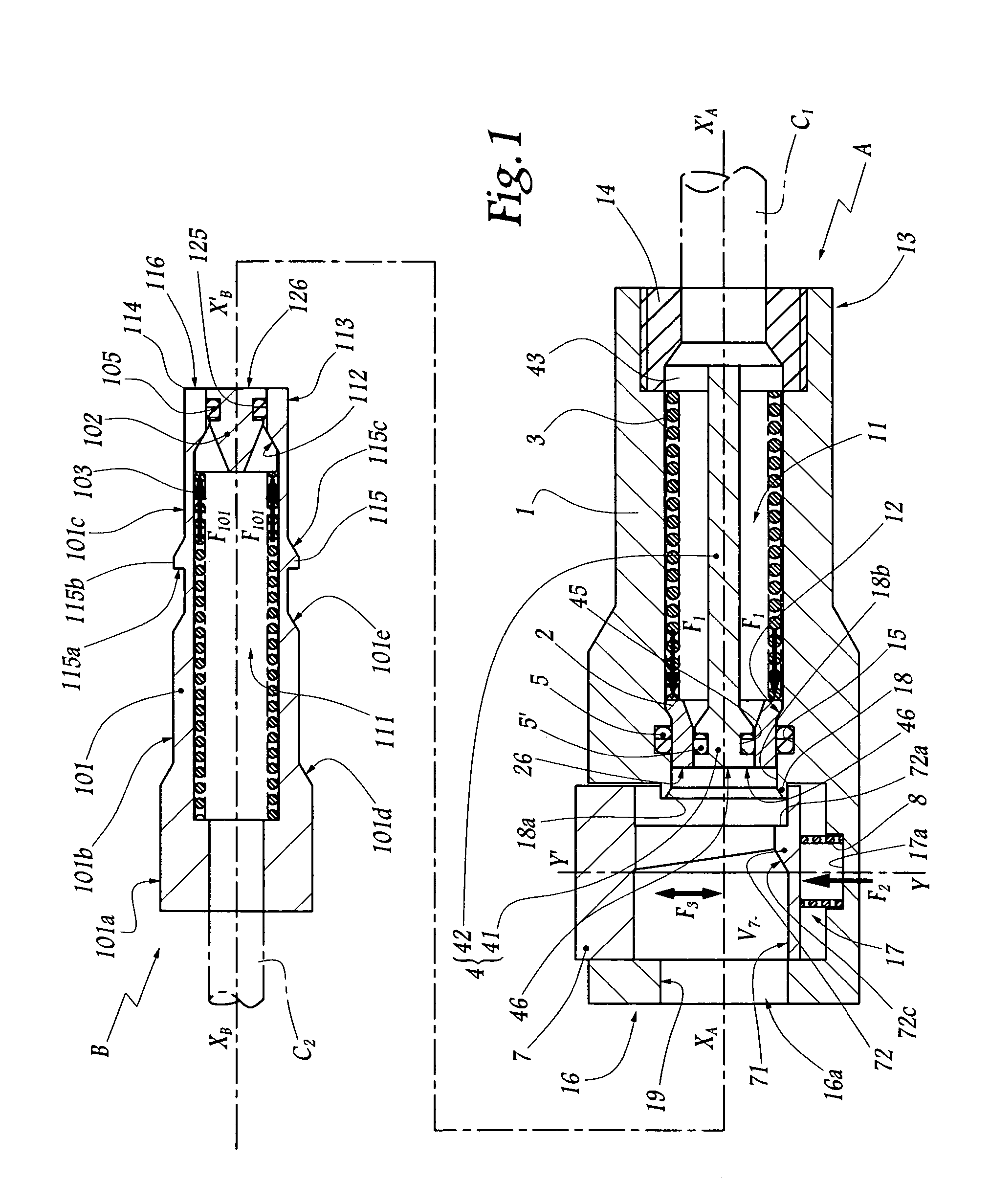

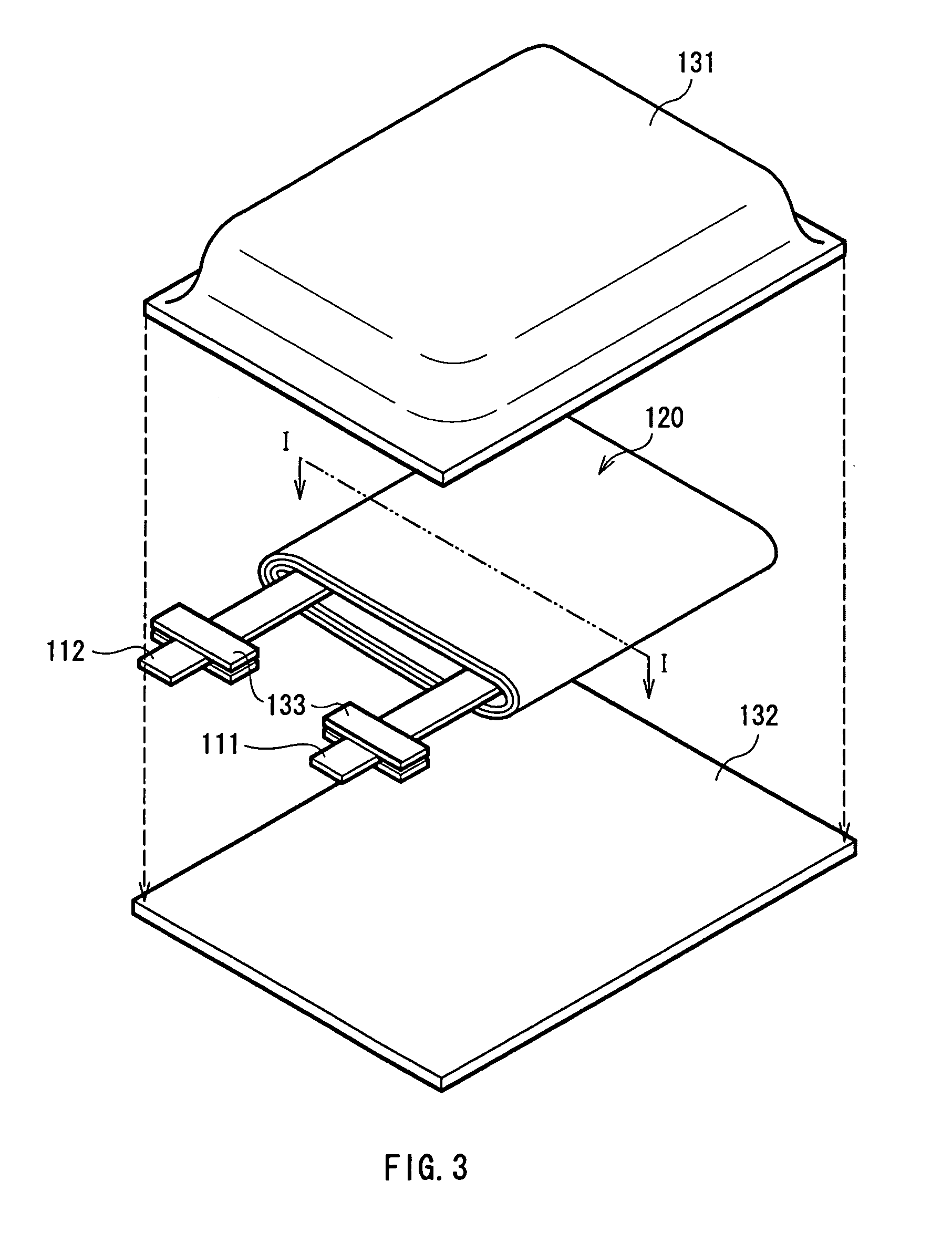

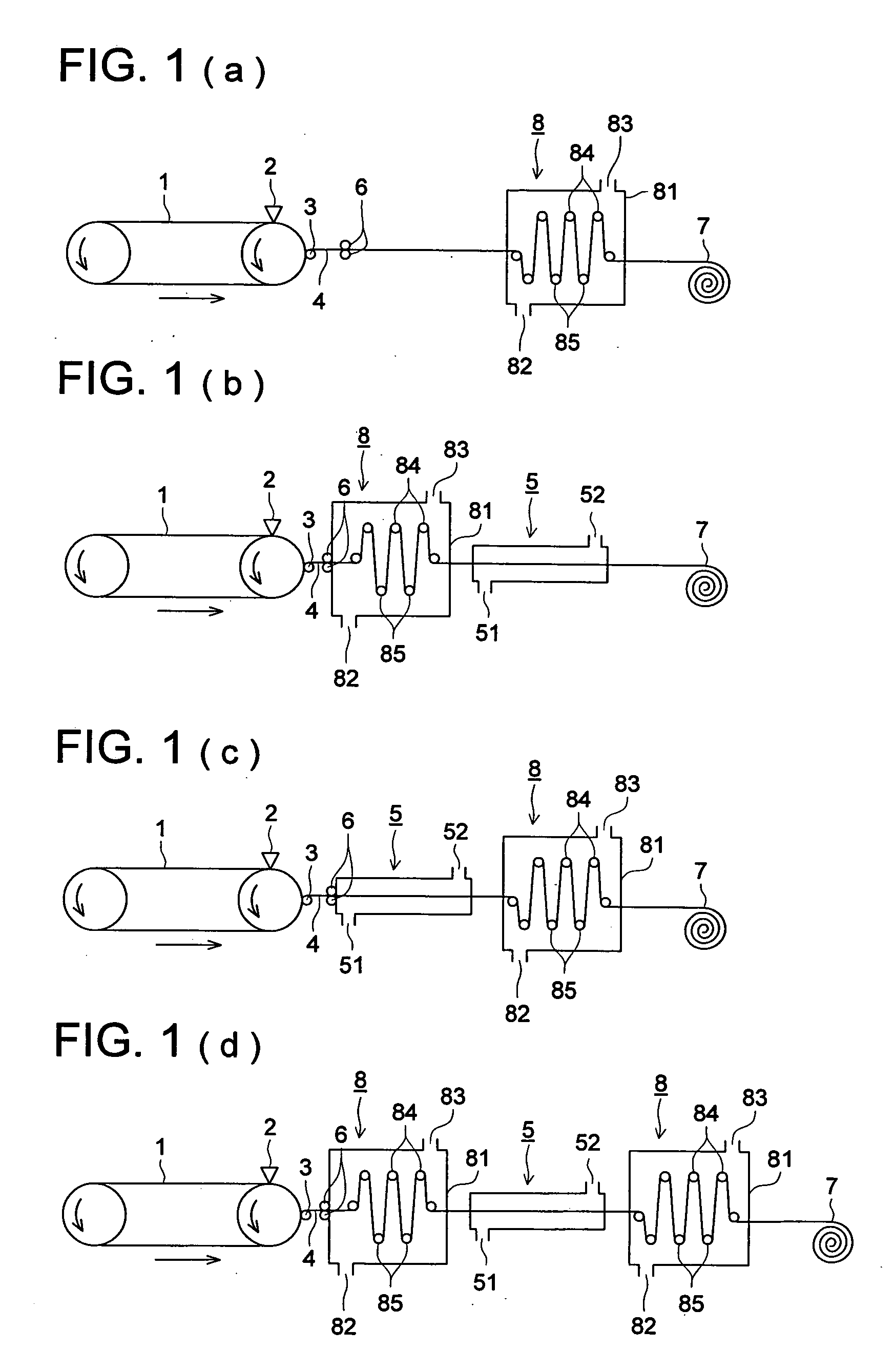

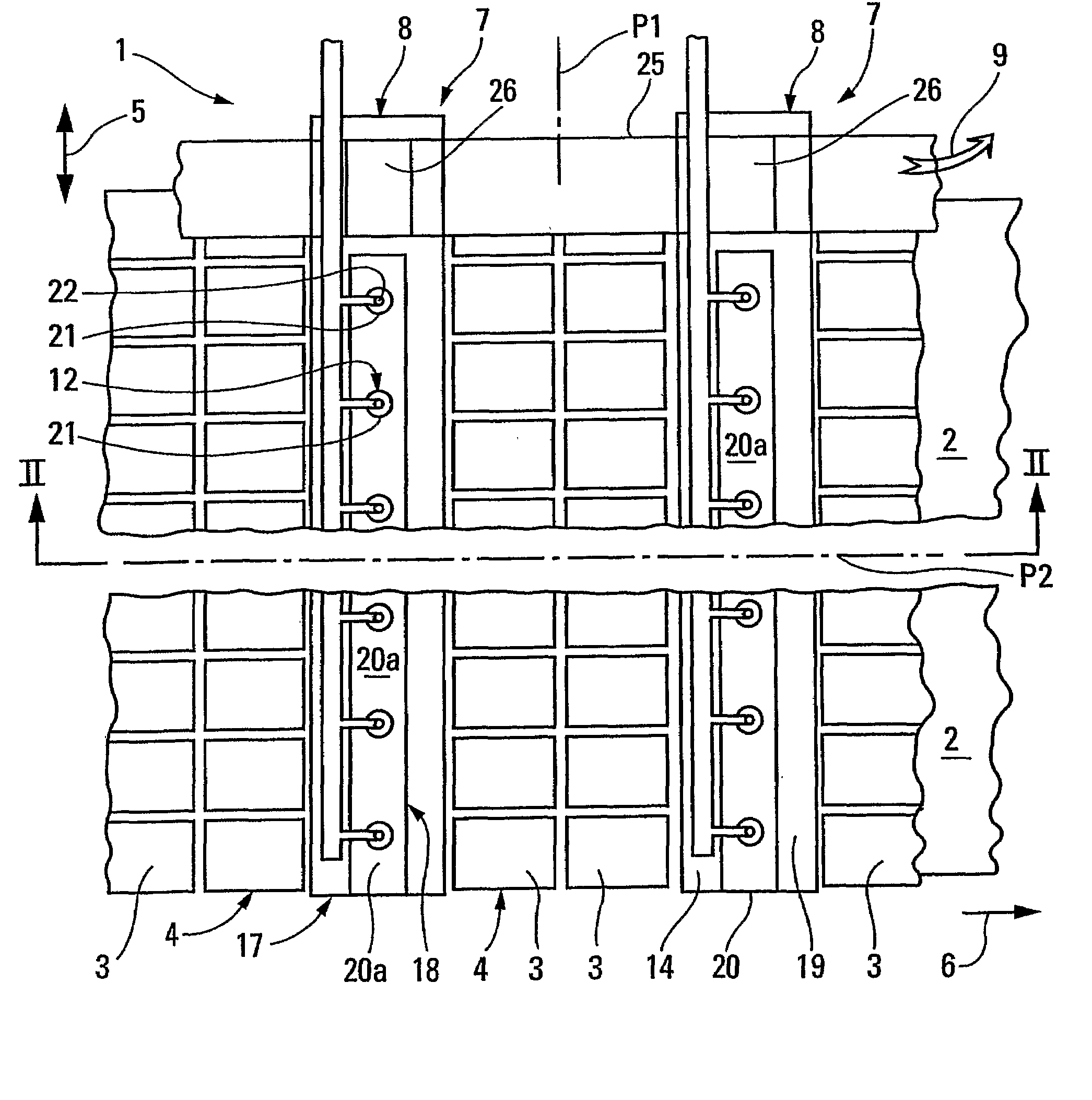

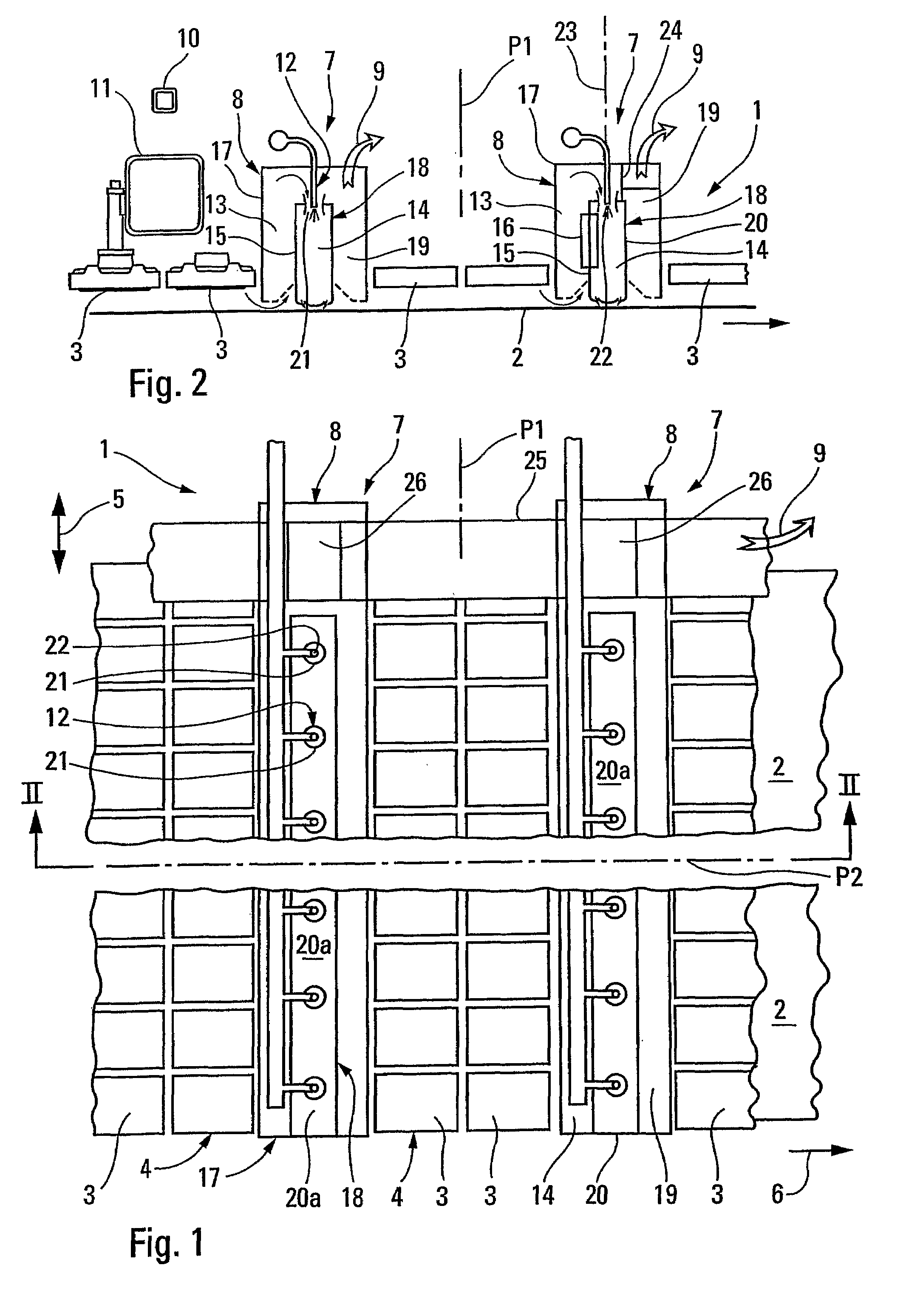

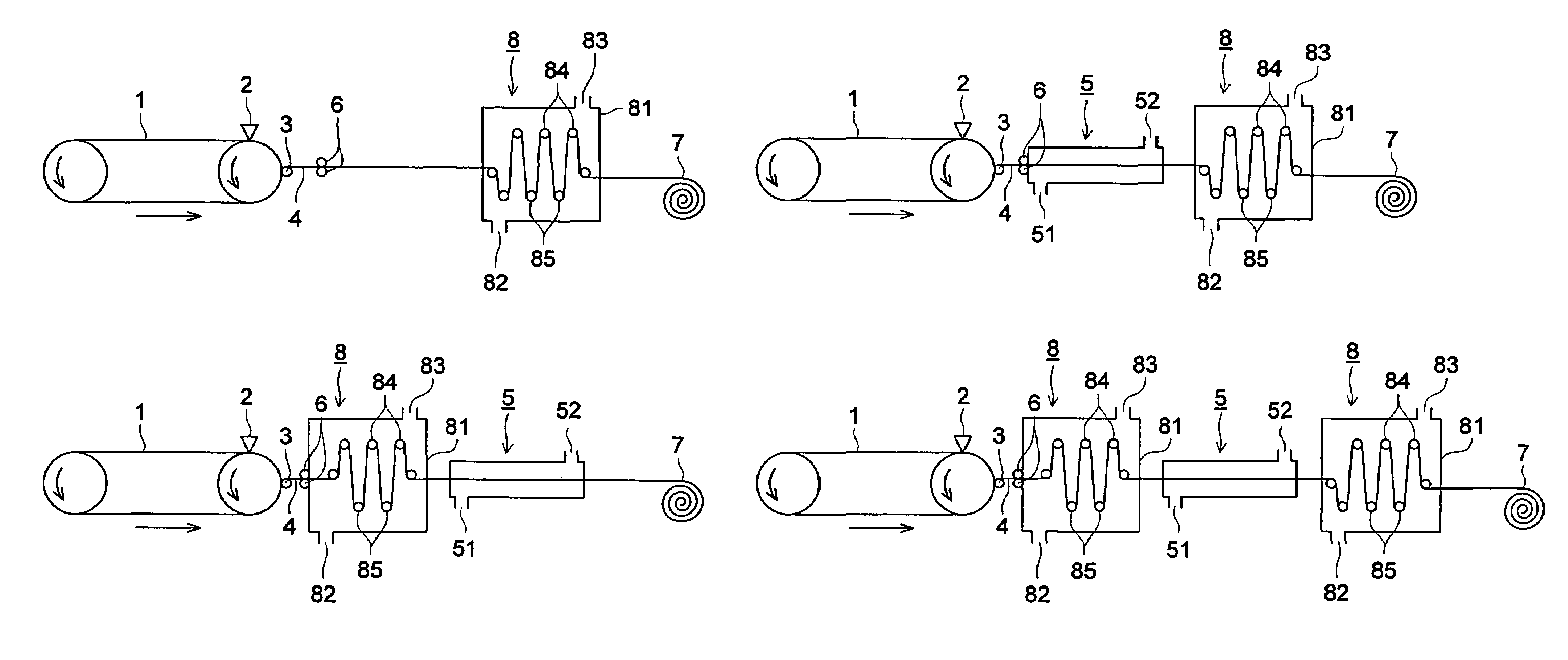

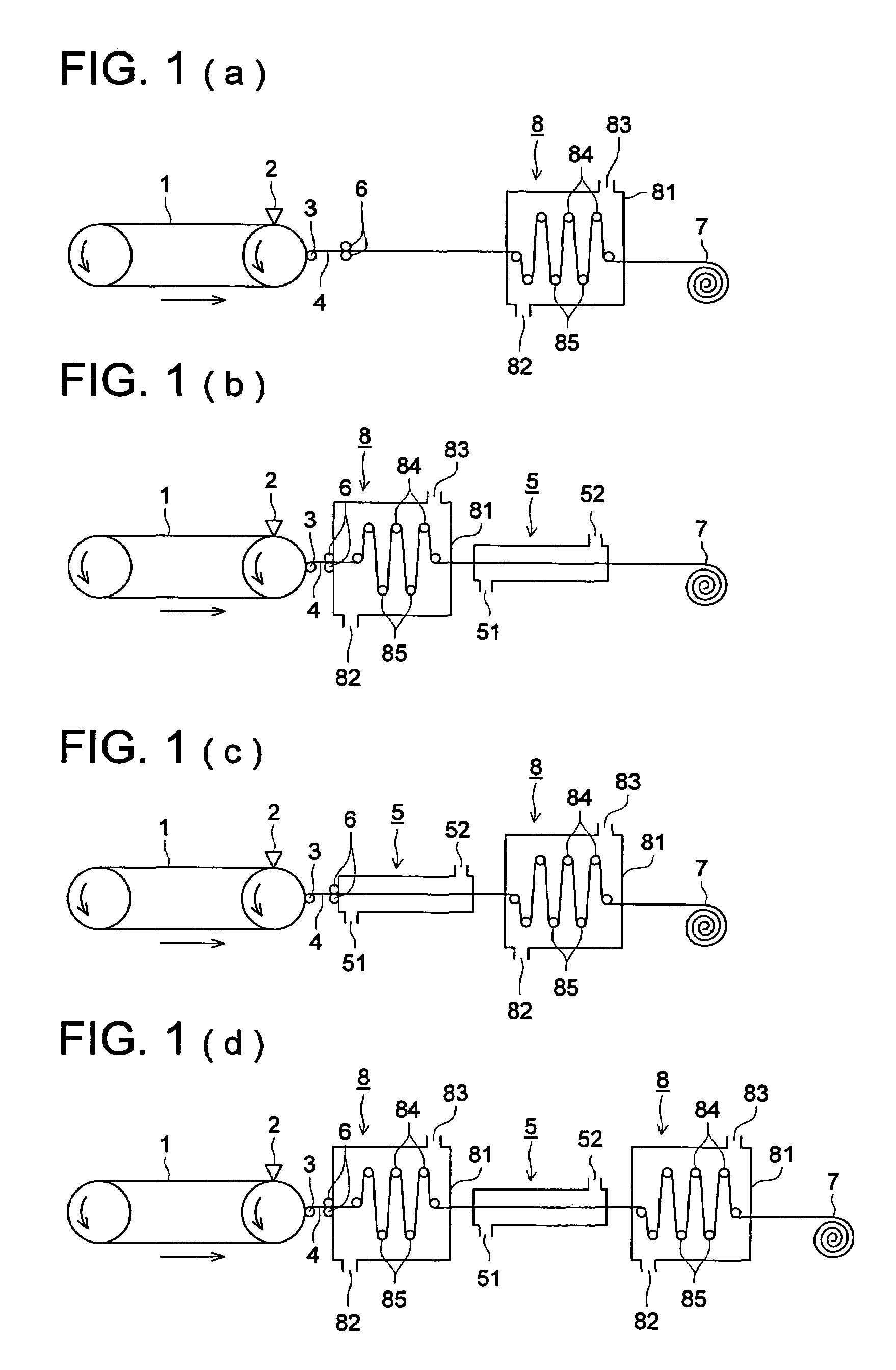

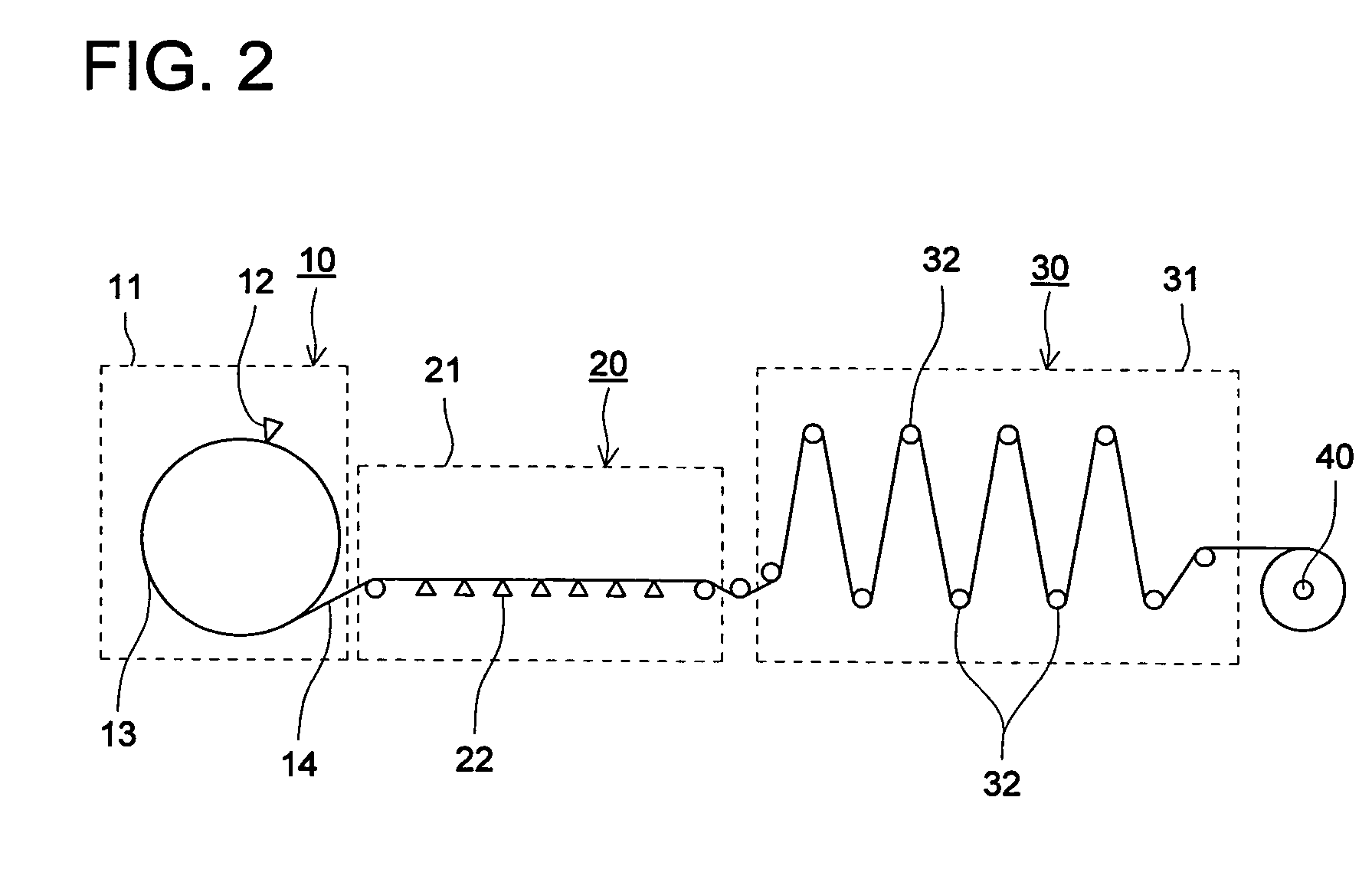

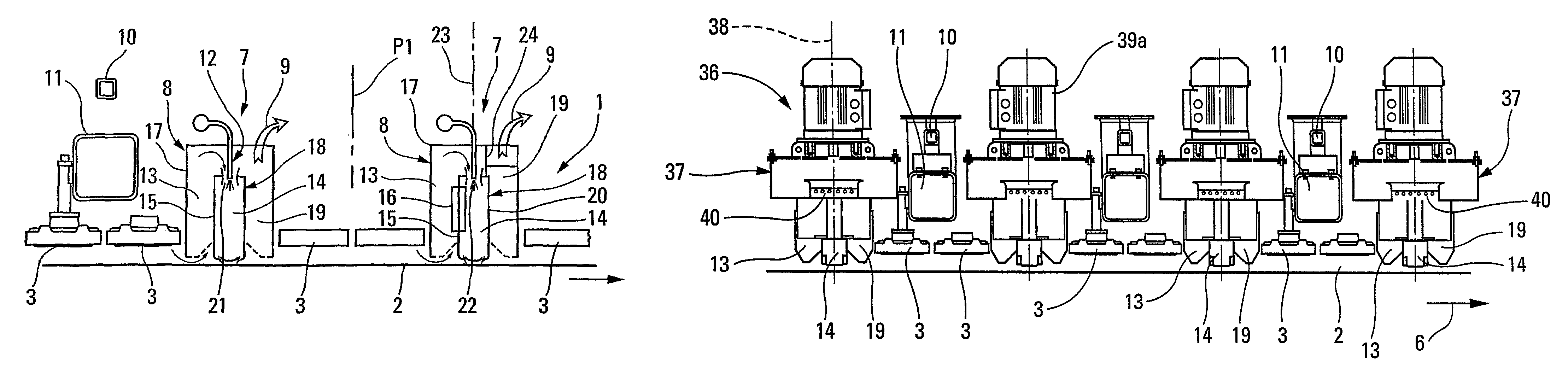

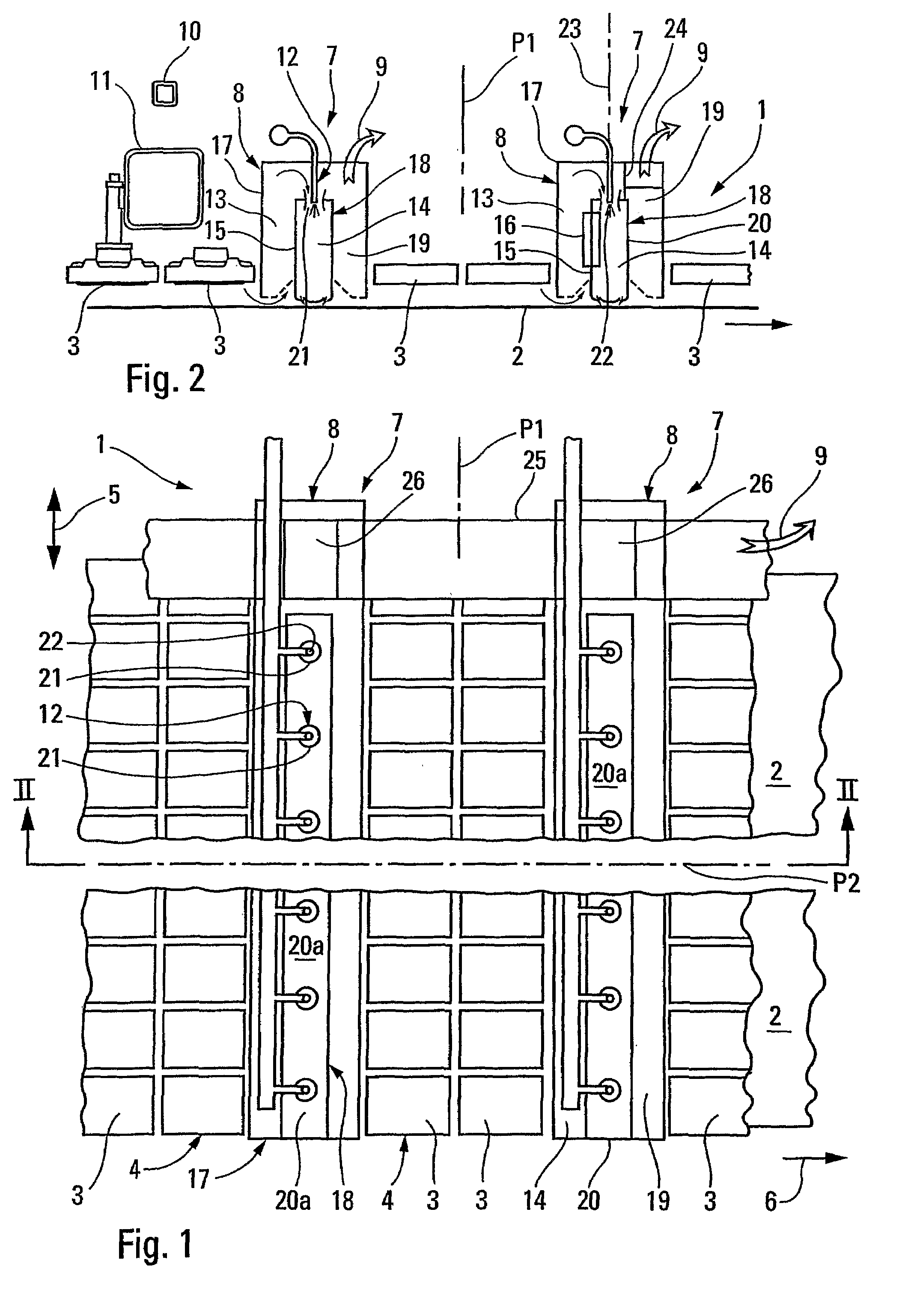

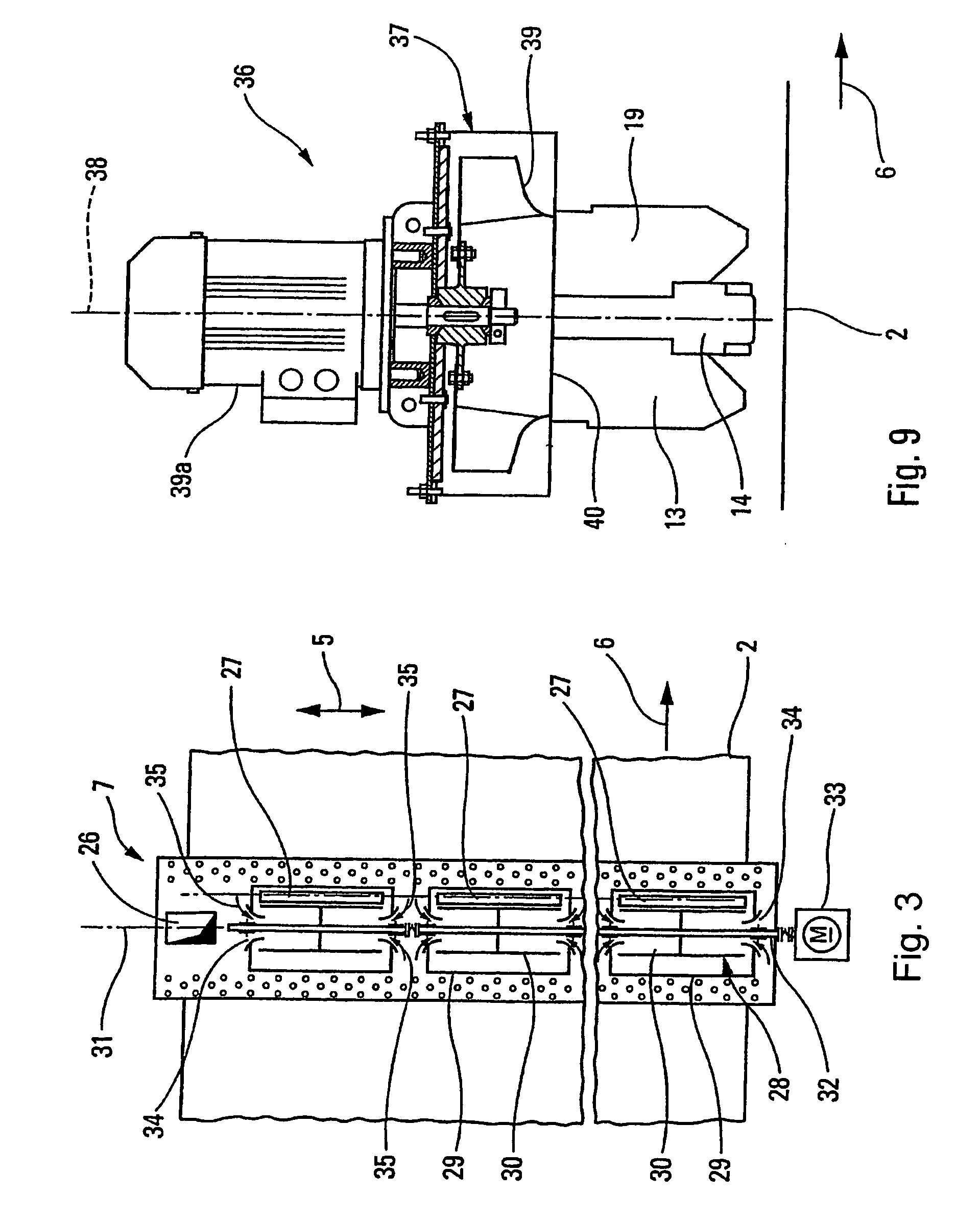

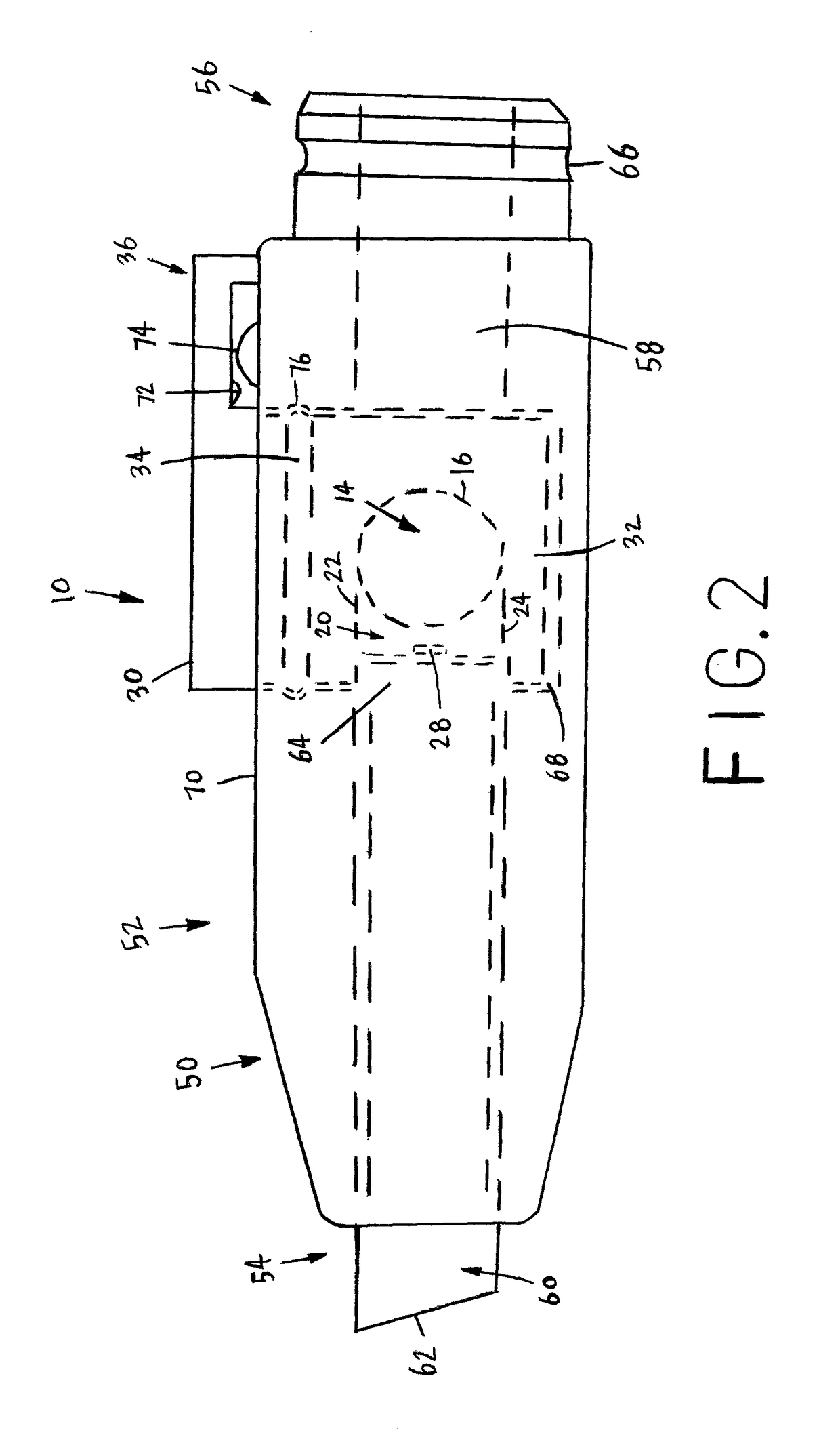

Drier Installation for Drying Web

ActiveUS20080256818A1Consumption of mechanical energyReduce investmentDrying solid materials with heatDrying gas arrangementsEngineeringCombustion products

A drier installation (1) for drying web (2), more particularly paper, which installation is provided for drying a maximum web width, the installation (1) comprises gas-heated radiant elements (3) for radiating the web, arranged according to at least one row (4) stretching out in the transversal (5) direction over the substantially entire maximum web width. The installation (1) comprises at least a transversal convective system (7, 36) equipped with suction and blowing devices (8) for sucking at least part of the combustion products produced by the radiant elements (3) by means of a suction duct (13) and for blowing this pa o the combustion products towards the web (2) by means of a blowing duct (14). Both suction (13) and blowing (14) ducts stretch out in the transversal (5) direction of the web (2). The convective system (7, 36 comprising at least a mixing device (12, 22, 28, 37, 46) installed opposite of the passing web (2) in relation to corresponding suction (13) and blowing (14) ducts and arranged so as to suck and / or blow the combustion products. The drier installation as subject of the present invention is characterized in that the vector average of the projections (V1, V2, V3, V5, V6, V7, V8) in a plane (P1) perpendicular to the web ( ) and stretching out in the transversal (5) direction of the web (2), has component (V4) parallel to the web (2) that is smaller than the maximum web width of the web (2), the vectors representing the respective trajectories of the different jets of sucked and / or blown combustion products.

Owner:SOLARONICS

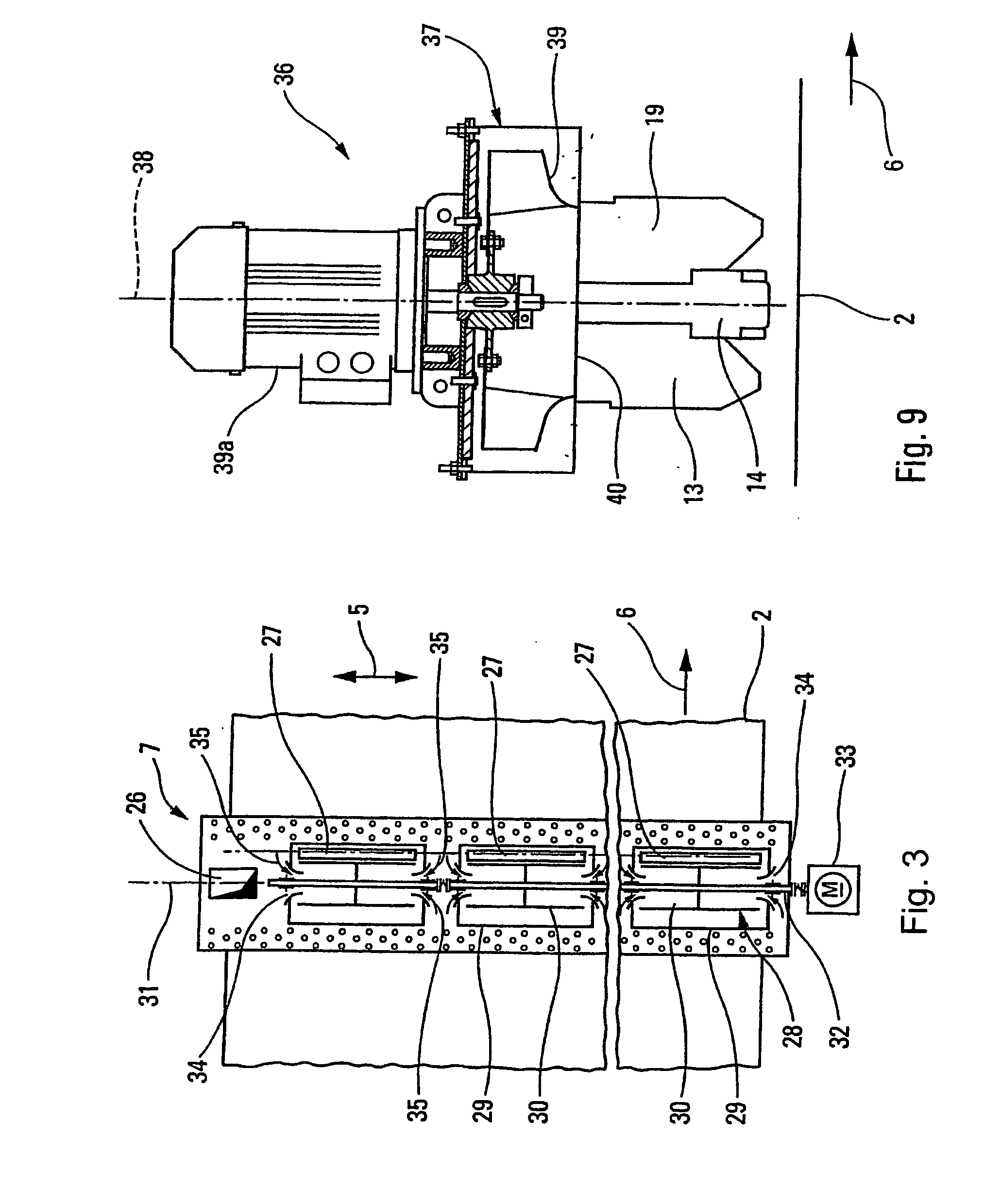

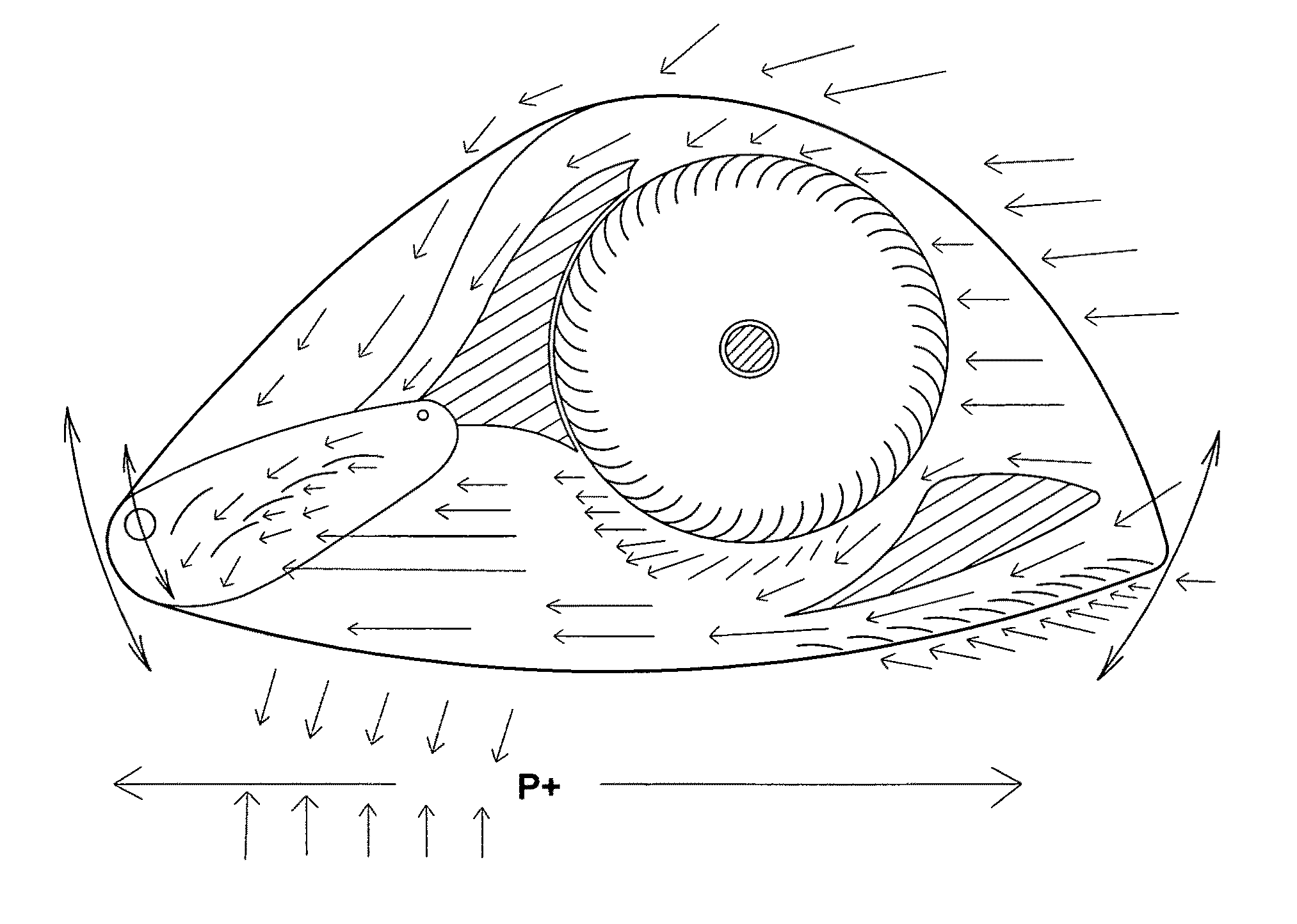

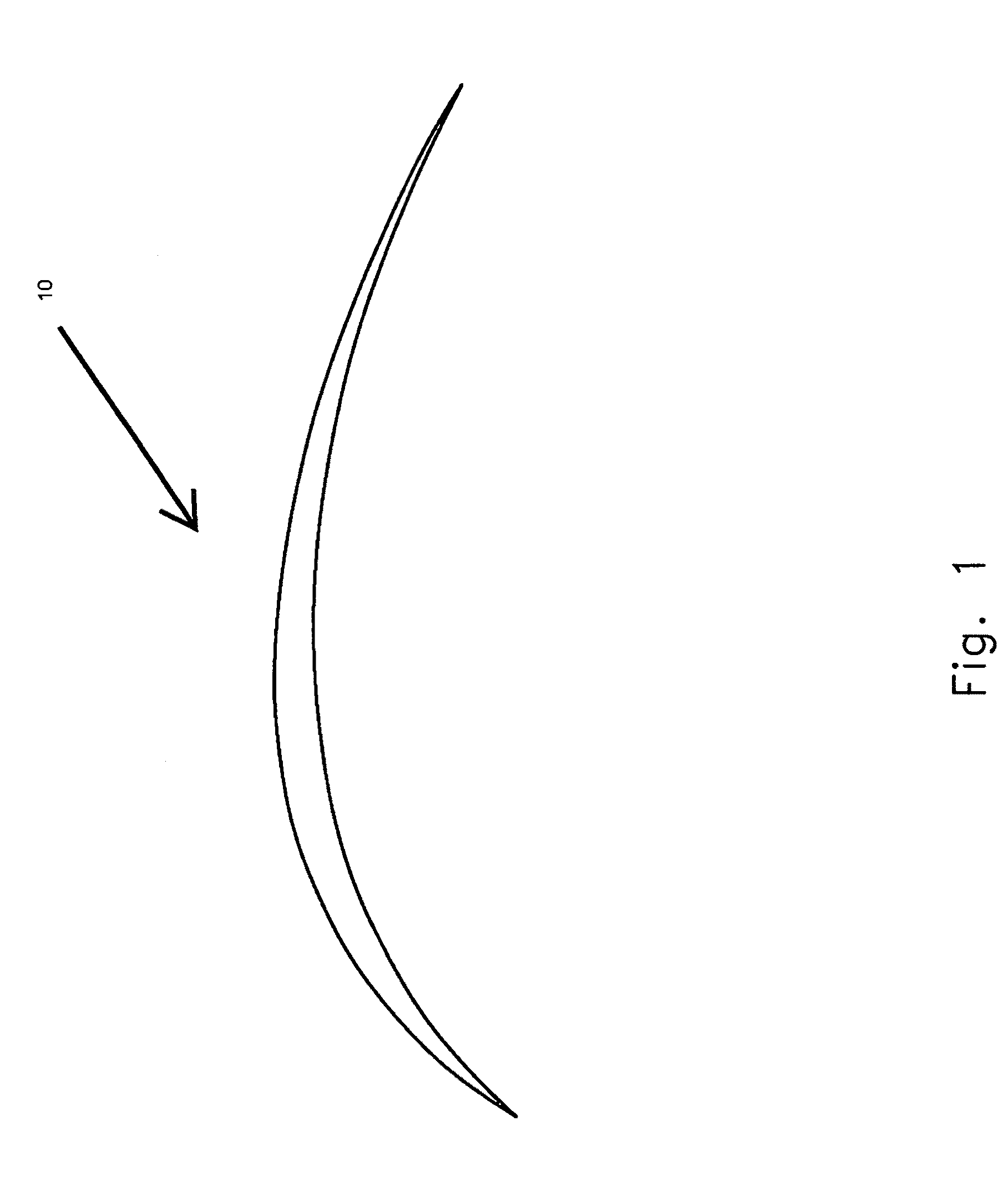

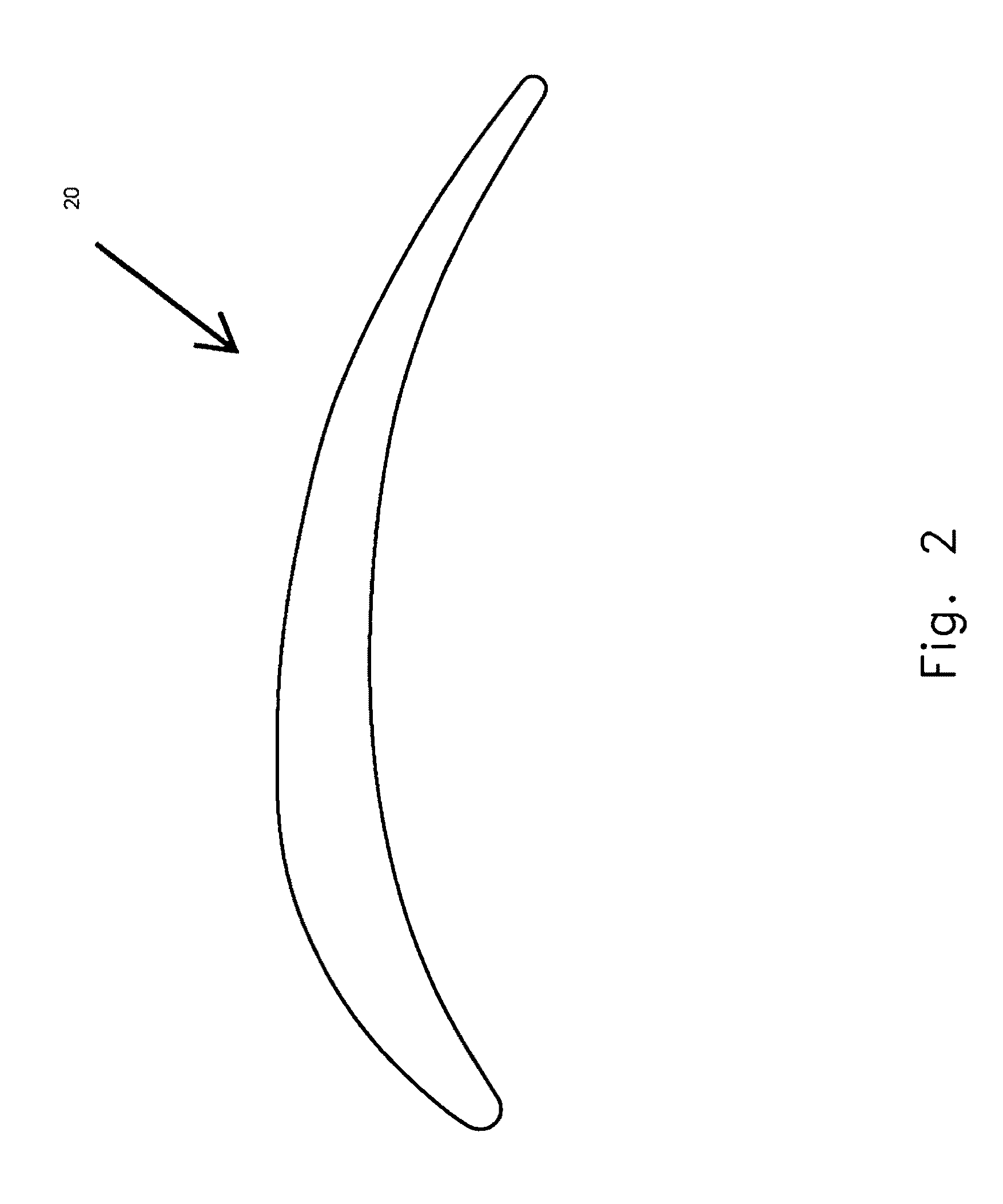

Fan, airfoil and vehicle propulsion systems

InactiveUS20100150714A1Preferred liftPreferred thrustCircumferential flow pumpsPump componentsAviationJet aeroplane

Vehicle propulsion systems and methods of propulsion are disclosed, as well as embodiments of fans and airfoils, technology that in some applications of the invention can provide both lift and thrust, and propulsion via cross flow fan, manifold and a plurality of airfoils. In some embodiments the invention is directed to the production of lift and thrust, and propulsion generally, based from air produced by a cross flow fan in accordance with the invention disclosed herein. In still further embodiments, lift and thrust may yet be generated from air produced from the cross flow fan even when unpowered, such as in a loss of power or in a stall condition. Applications of the invention apply broadly to propulsion systems, generally; however, some preferred embodiments have particular application for vehicles characterized or used in application such as traditional private and commercial aircraft, ground effects vehicles, military applications, amphibious applications, aerospace, aeronautical, and non-traditional vehicles such as experimental air planes, space craft, hover craft, and the like. The invention in some embodiments comprises technologies addressing preferred air flow, lift, and thrust and the reduction of drag and circulation losses. The invention may be further applicable for incorporation in aircraft and other vehicles wherein the ability to maximize initial vertical lift and takeoff is important, such as in instant take-off and landing, as well as the abilities to hover, to control the flight and landing of aircraft, and control in power-loss scenarios, addressing the prevention of stalls and allowing for controlled descents under continued propulsion. In some embodiments, the invention is further applicable for aircraft, shuttles and other vehicles as a ram jet engine system as a further alternative propulsion technology, having no requirement for forward movement for propulsion upon take-off.

Owner:KOLACNY GORDON S +1

Cellulose ester film and its manufacturing method, optical film, polarizing plate and liquid crystal display

ActiveUS7445821B2Easy to adjustEasy to slideLiquid crystal compositionsPolarising elementsCelluloseLiquid-crystal display

Disclosed is a cellulose ester film containing cellulose ester and microparticles having an average primary particle diameter of from 0.1 to 1.0 μm, wherein a relative standard deviation of a primary particle diameter of the microparticles is from 1 to 20%, and wherein the cellulose ester film has a surface with a peak density of from 1,000 to 8,000 (1 / mm2).

Owner:KONICA MINOLTA OPTO

Fan, airfoil and vehicle propulsion systems

InactiveUS8157520B2Preferred liftPreferred thrustCircumferential flow pumpsPump componentsAviationJet engine

Vehicle propulsion systems and methods of propulsion are disclosed, as well as embodiments of fans and airfoils, technology that in some applications of the invention can provide both lift and thrust, and propulsion via cross flow fan, manifold and a plurality of airfoils. In some embodiments the invention is directed to the production of lift and thrust, and propulsion generally, based from air produced by a cross flow fan in accordance with the invention disclosed herein. In still further embodiments, lift and thrust may yet be generated from air produced from the cross flow fan even when unpowered, such as in a loss of power or in a stall condition. Applications of the invention apply broadly to propulsion systems, generally; however, some preferred embodiments have particular application for vehicles characterized or used in application such as traditional private and commercial aircraft, ground effects vehicles, military applications, amphibious applications, aerospace, aeronautical, and non-traditional vehicles such as experimental air planes, space craft, hover craft, and the like. The invention in some embodiments comprises technologies addressing preferred air flow, lift, and thrust and the reduction of drag and circulation losses. The invention may be further applicable for incorporation in aircraft and other vehicles wherein the ability to maximize initial vertical lift and takeoff is important, such as in instant take-off and landing, as well as the abilities to hover, to control the flight and landing of aircraft, and control in power-loss scenarios, addressing the prevention of stalls and allowing for controlled descents under continued propulsion. In some embodiments, the invention is further applicable for aircraft, shuttles and other vehicles as a ram jet engine system as a further alternative propulsion technology, having no requirement for forward movement for propulsion upon take-off.

Owner:KOLACNY GORDON S +1

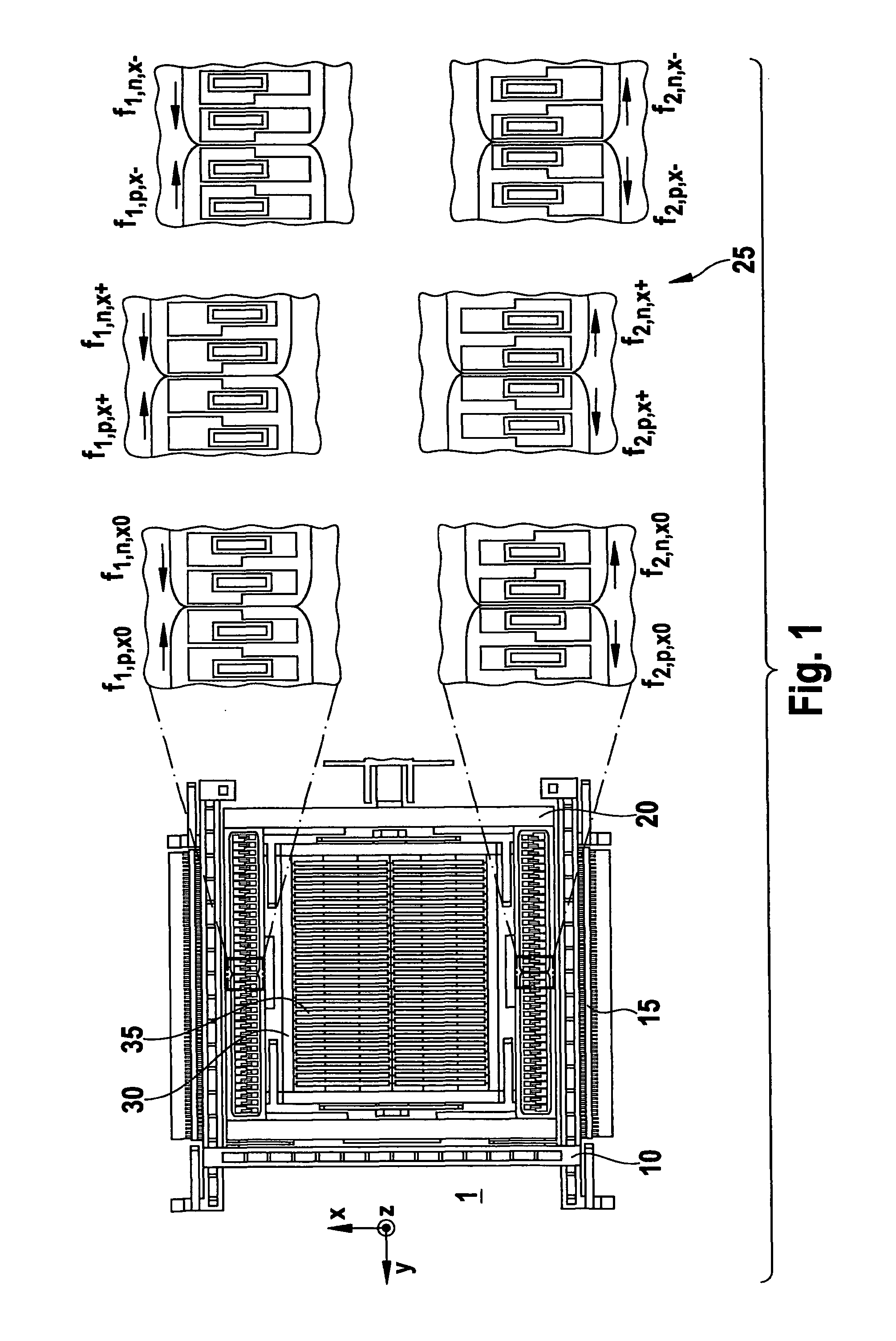

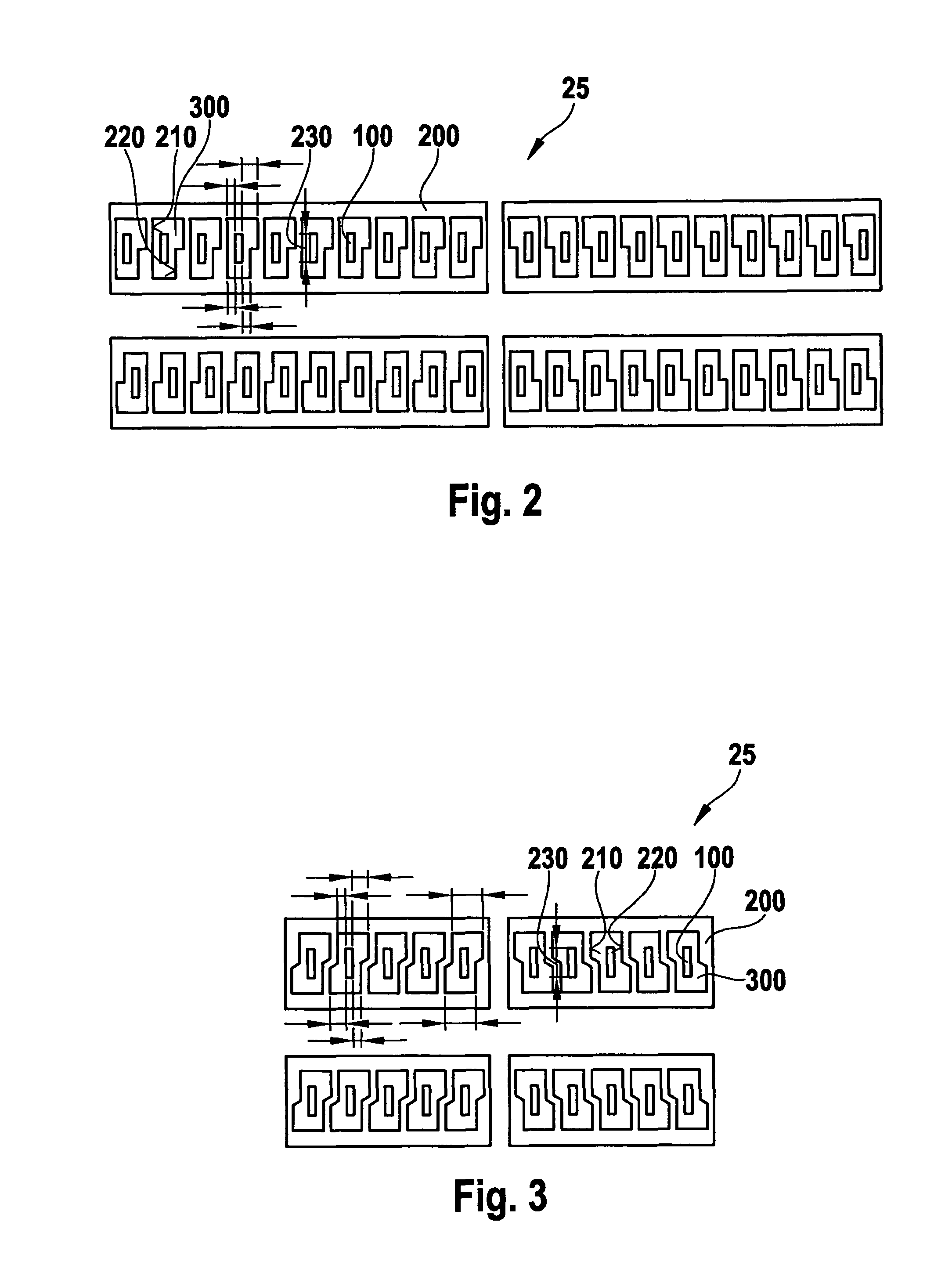

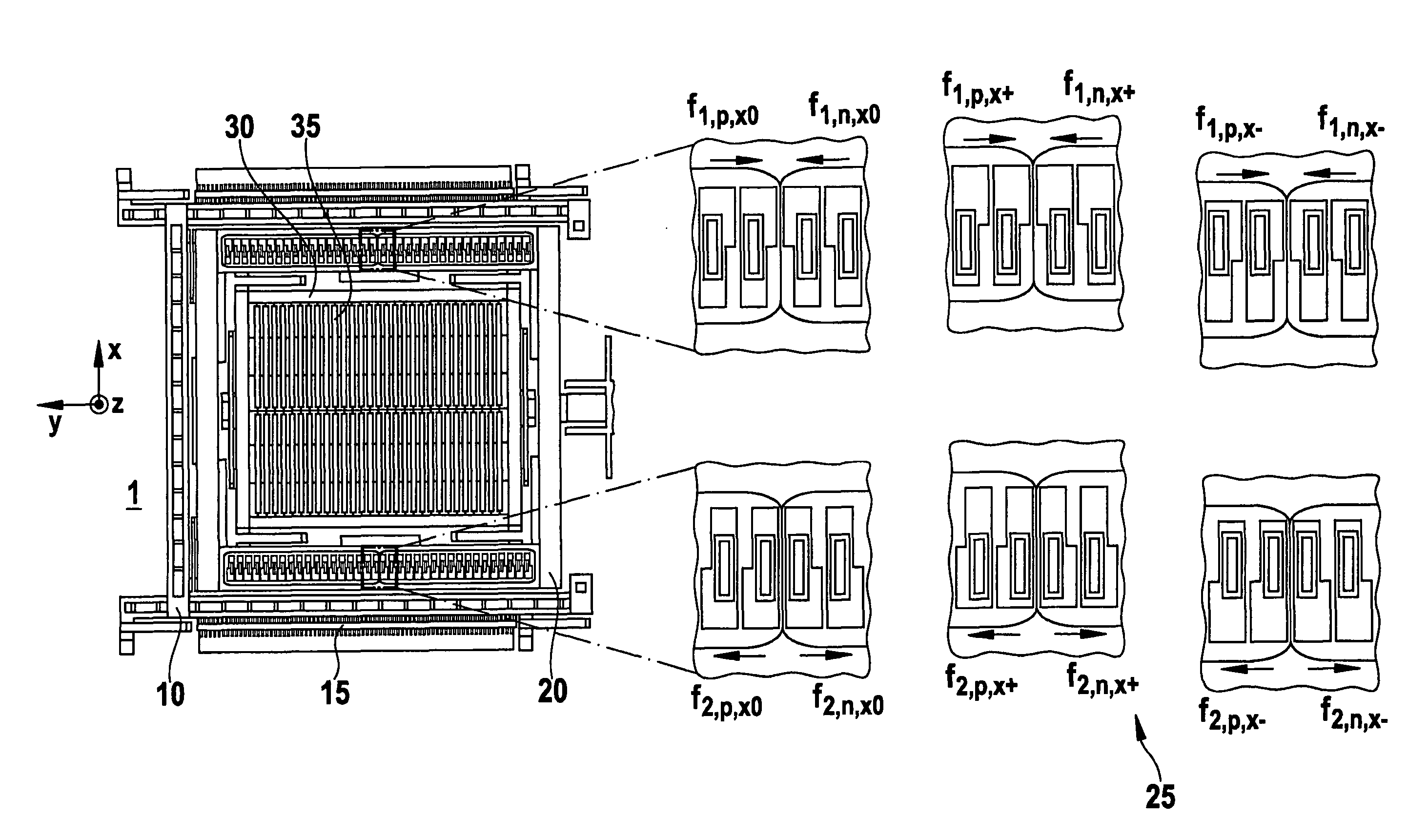

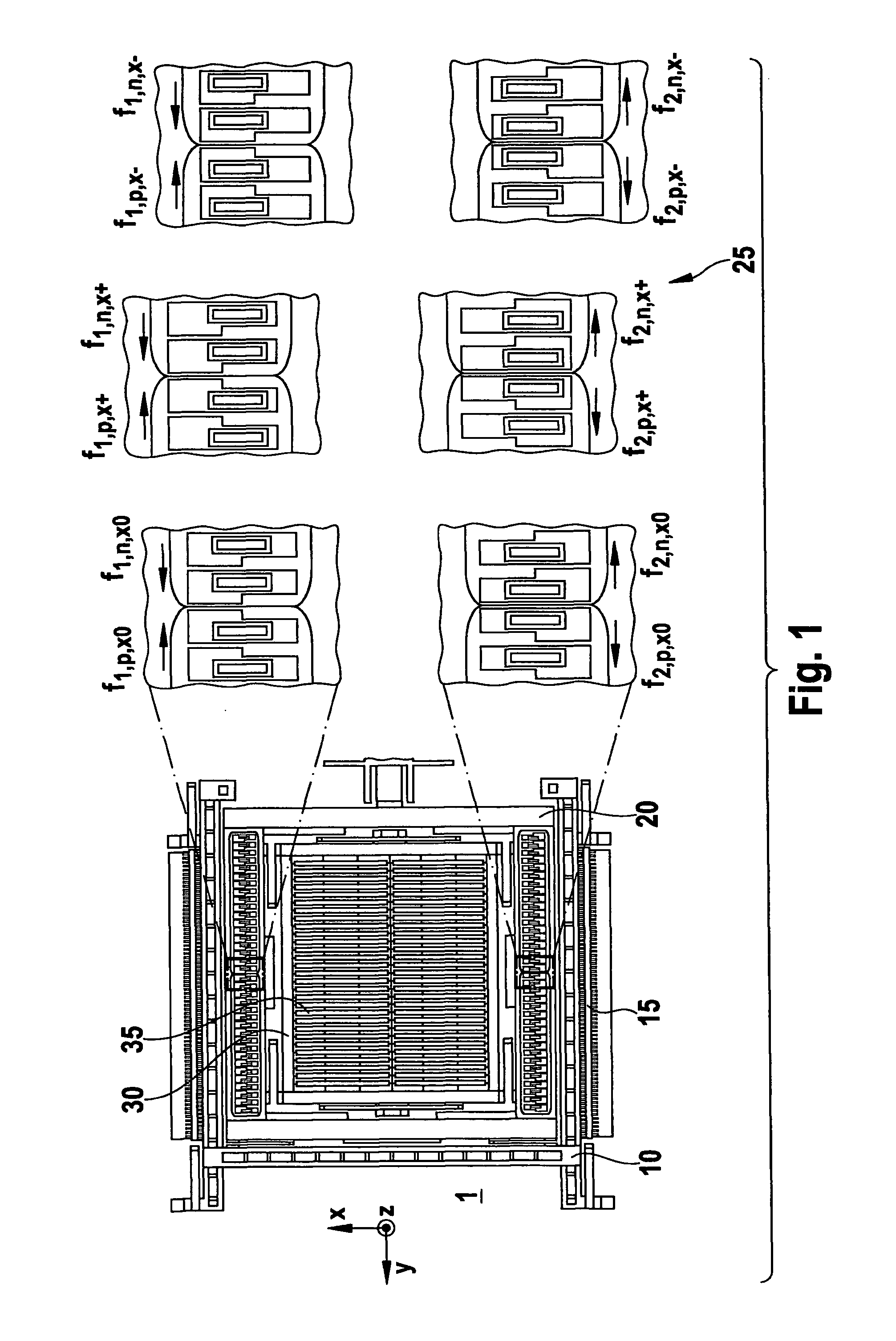

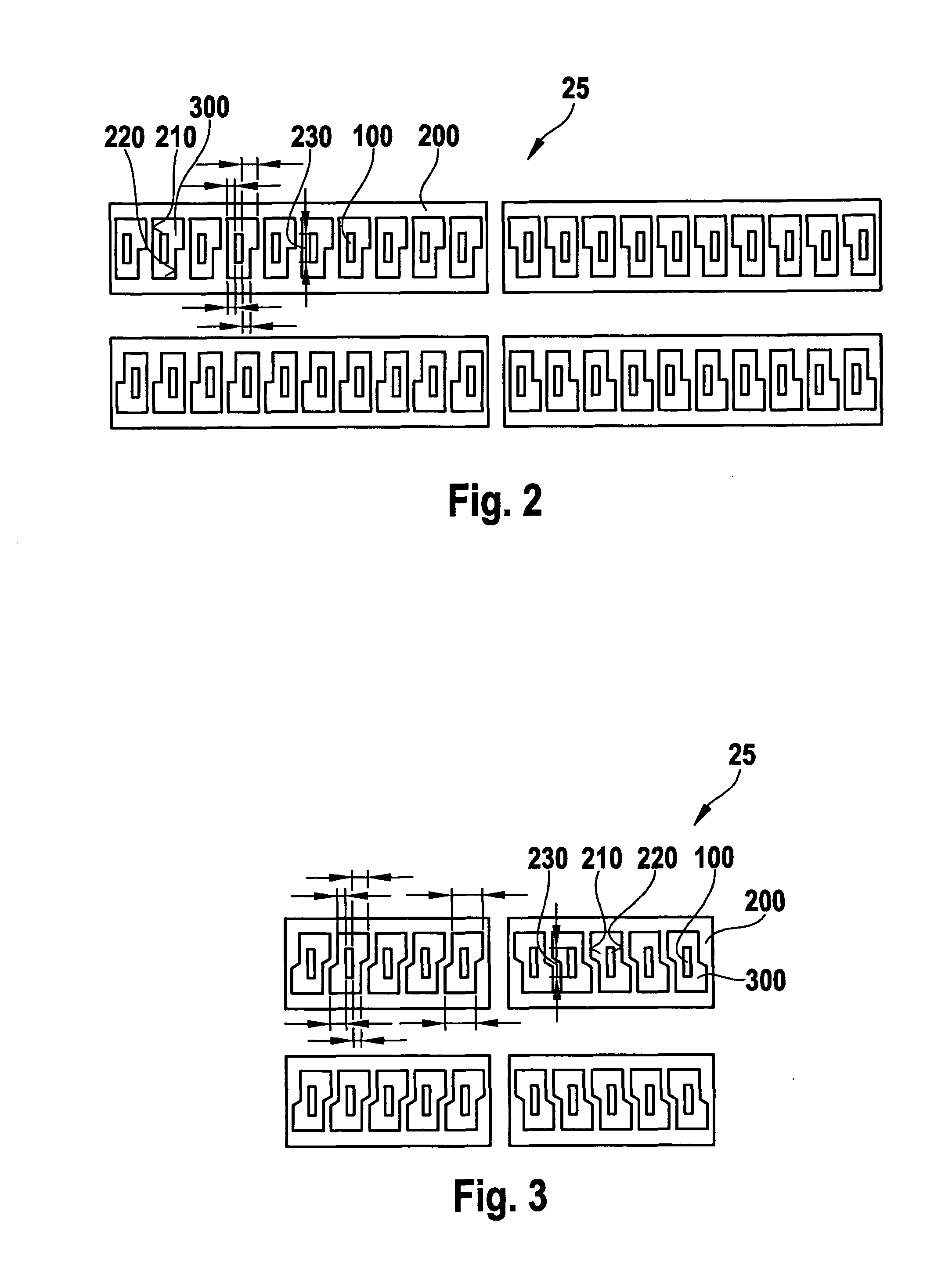

Rotation rate sensor having a quadrature compensation pattern

ActiveUS8375786B2Less surfaceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsOptoelectronicsIntermediate space

A rotation-rate sensor having at least one quadrature compensation pattern, which includes at least one first electrode and one second electrode. The second electrode has a first electrode surface and a second electrode surface which are situated opposite to each other. The first electrode is situated in an intermediate space, between the first electrode surface and the second electrode surface. The first electrode surface and also the second electrode surface, over their extension, are at a different distance from the first electrode. The first electrode surface and the second electrode surface of the second electrode are at generally the same distance from each other, over their extension.

Owner:ROBERT BOSCH GMBH

Rotation-Rate Sensor Having A Quadrature Compensation Pattern

ActiveUS20110126621A1LessLess surfaceAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsOptoelectronicsIntermediate space

A rotation-rate sensor having at least one quadrature compensation pattern, which includes at least one first electrode and one second electrode. The second electrode has a first electrode surface and a second electrode surface which are situated opposite to each other. The first electrode is situated in an intermediate space, between the first electrode surface and the second electrode surface. The first electrode surface and also the second electrode surface, over their extension, are at a different distance from the first electrode. The first electrode surface and the second electrode surface of the second electrode are at generally the same distance from each other, over their extension.

Owner:ROBERT BOSCH GMBH

Drier installation for drying web

ActiveUS7918040B2Consume energyEnergy lossDrying solid materials with heatDrying gas arrangementsEngineeringCombustion products

A drier installation (1) for drying web (2), more particularly paper, which installation is provided for drying a maximum web width, the installation (1) comprises gas-heated radiant elements (3) for radiating the web, arranged according to at least one row (4) stretching out in the transversal (5) direction over the substantially entire maximum web width. The installation (1) comprises at least a transversal convective system (7, 36) equipped with suction and blowing devices (8) for sucking at least part of the combustion products produced by the radiant elements (3) by means of a suction duct (13) and for blowing this pa o the combustion products towards the web (2) by means of a blowing duct (14). Both suction (13) and blowing (14) ducts stretch out in the transversal (5) direction of the web (2). The convective system (7, 36 comprising at least a mixing device (12, 22, 28, 37, 46) installed opposite of the passing web (2) in relation to corresponding suction (13) and blowing (14) ducts and arranged so as to suck and / or blow the combustion products. The drier installation as subject of the present invention is characterized in that the vector average of the projections (V1, V2, V3, V5, V6, V7, V8) in a plane (P1) perpendicular to the web ( ) and stretching out in the transversal (5) direction of the web (2), has component (V4) parallel to the web (2) that is smaller than the maximum web width of the web (2), the vectors representing the respective trajectories of the different jets of sucked and / or blown combustion products.

Owner:SOLARONICS

Quick connection for removably joining two pipes and use of such a connection

ActiveUS20050081929A1Minimized dimensionLittle riskCouplingsThin material handlingDead volumeEngineering

The connection according to the invention is constituted by two elements, male and female, adapted to fit axially in each other and each comprising a body, inside which a valve is mobile. A fixed part of each element is adapted to displace the mobile valve of the other element when they are being fitted. The female element is provided with a locking member in which may be introduced a part of the male element and which is mobile in translation in a radial direction with respect to the axis of fit of the elements, between two positions in which it respectively allows or opposes the separation of the male and female elements; when these elements are separated, their respective fixed part and mobile valve together define complementary volumes of which the opposite surfaces may come into surface abutment on each other, this avoiding the formation of dead volumes capable of generating drainings or leakages.

Owner:STAUBLI FAVERGES SA

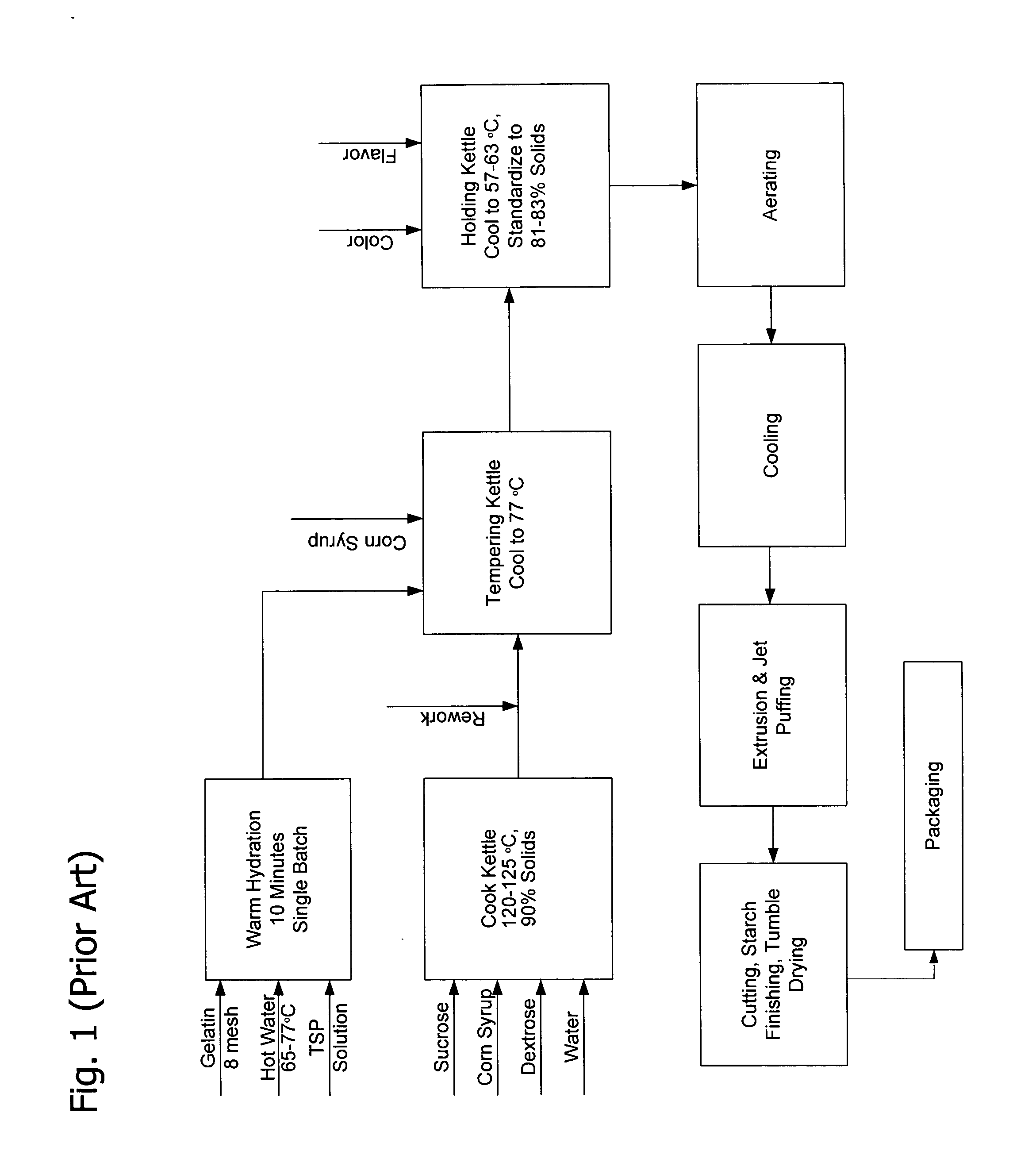

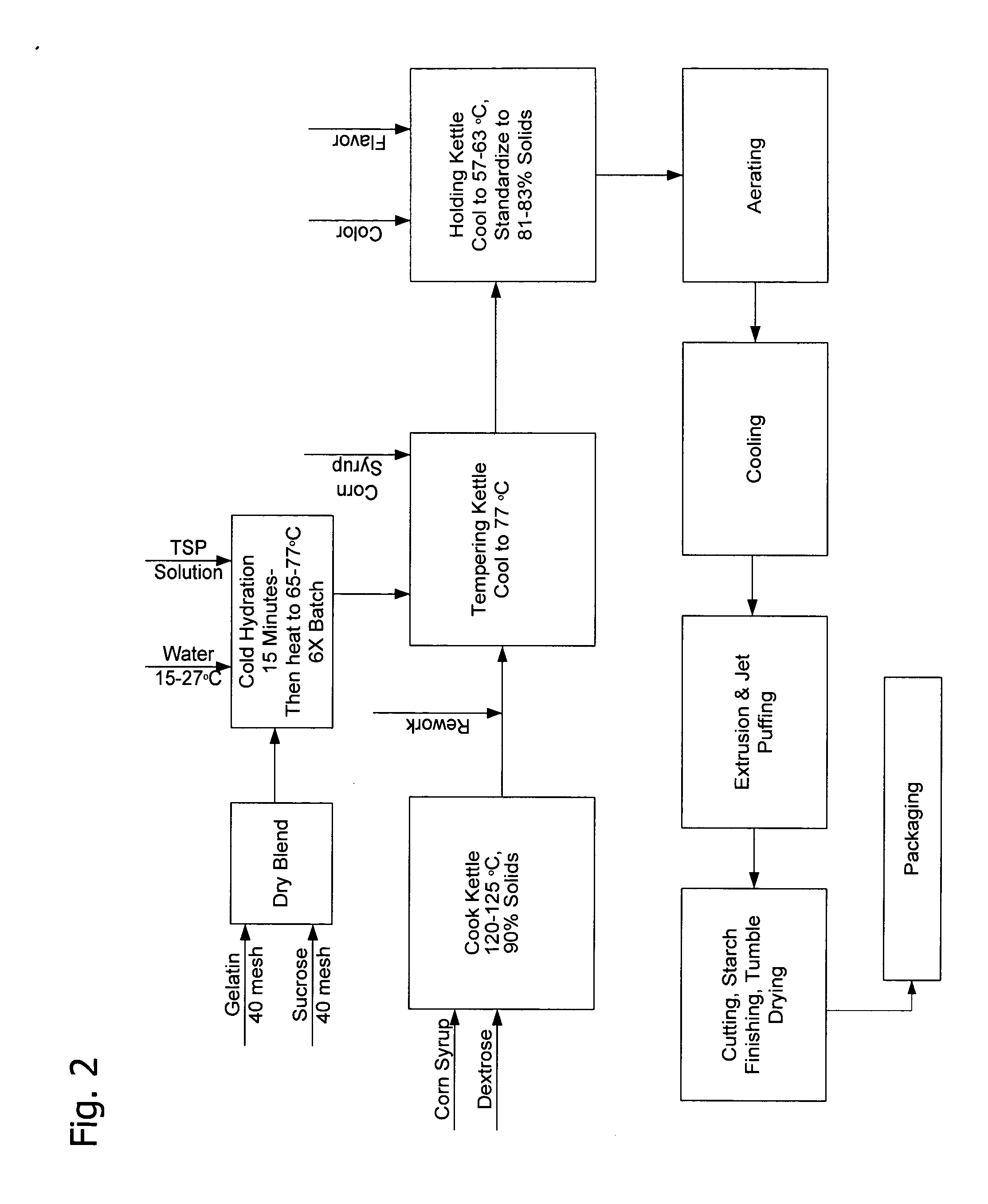

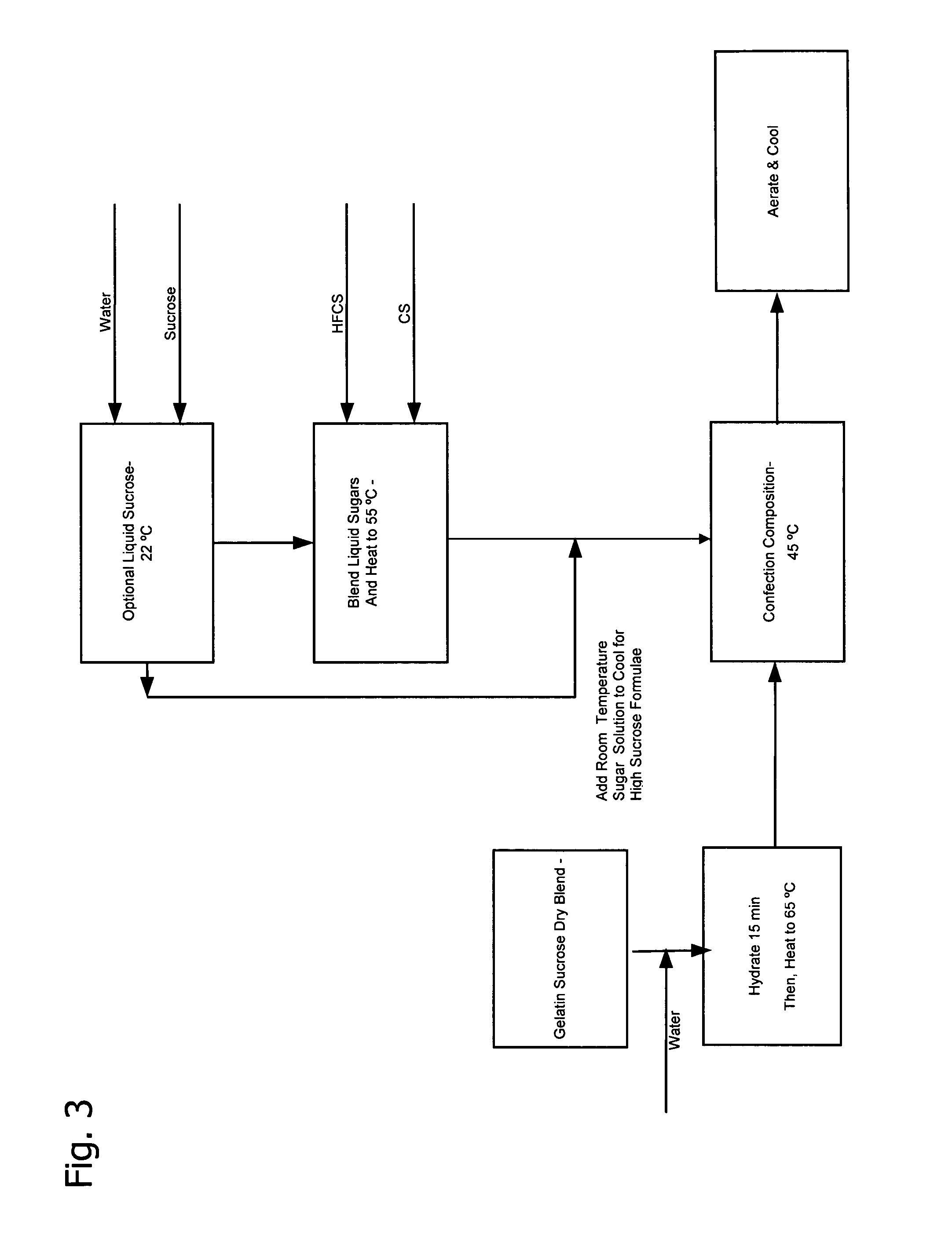

Process for manufacture of aerated confections with dry blend of sugar and gelatin

The typically employed step of separately hydrating gelatin in warm water for the preparation of aerated, gelatin-containing confections such as marshmallow is replaced by hydrating a dry blend of sucrose and gelatin in cold water prior to heating. The marshmallow products produced by this process are made more efficiently and have good string. The gelatin processed in this manner undergoes less cis isomerization than occurs during conventional processing. The invention improves processing for the production of marshmallow pieces, marshmallow fillers, e.g., for cookies and candies, dehydrated marshmallow bits and spoonable marshmallow toppings.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

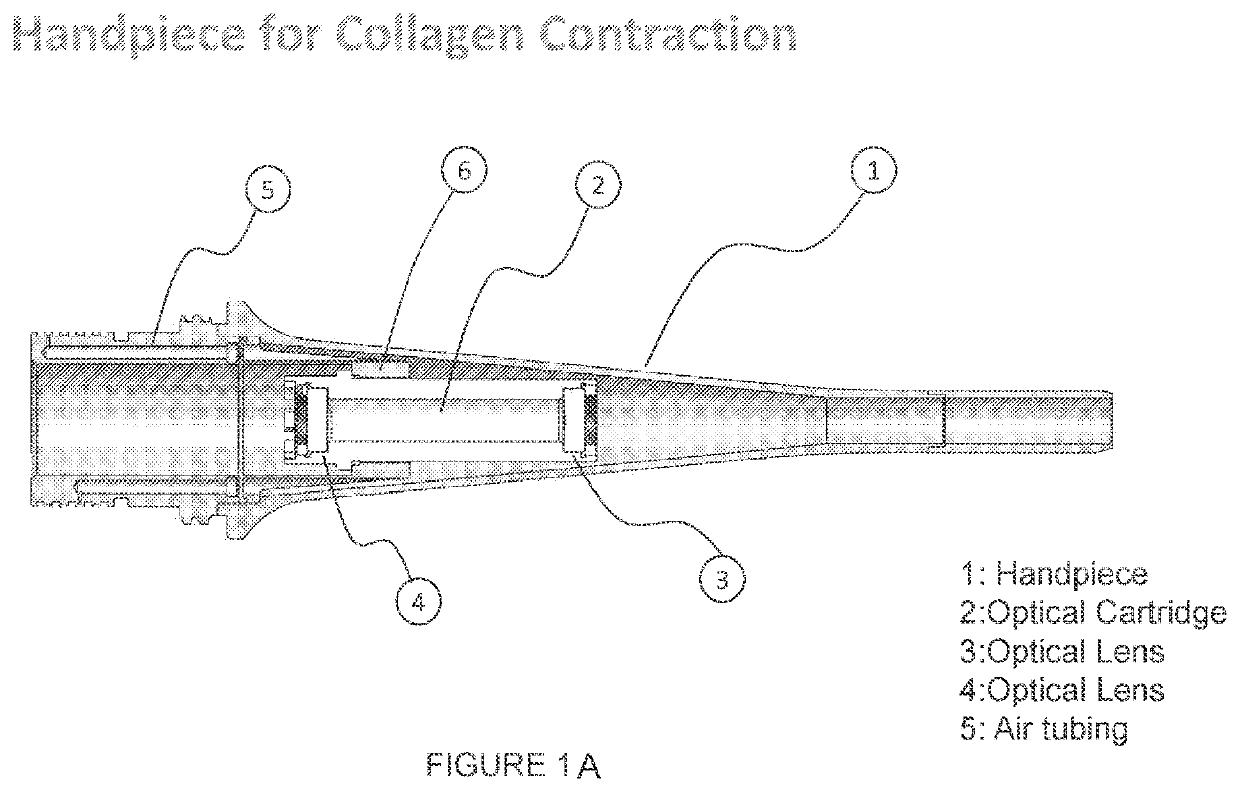

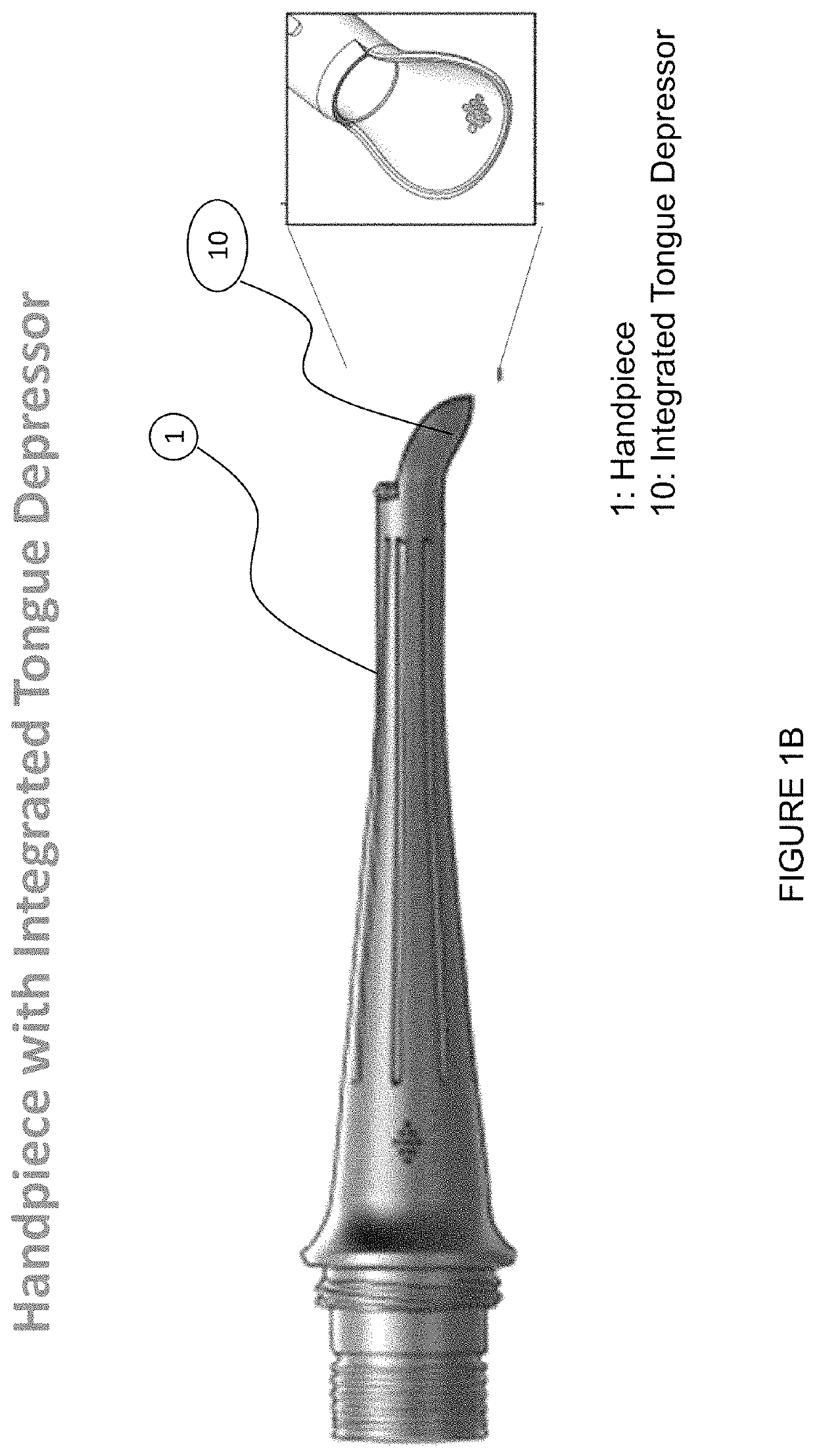

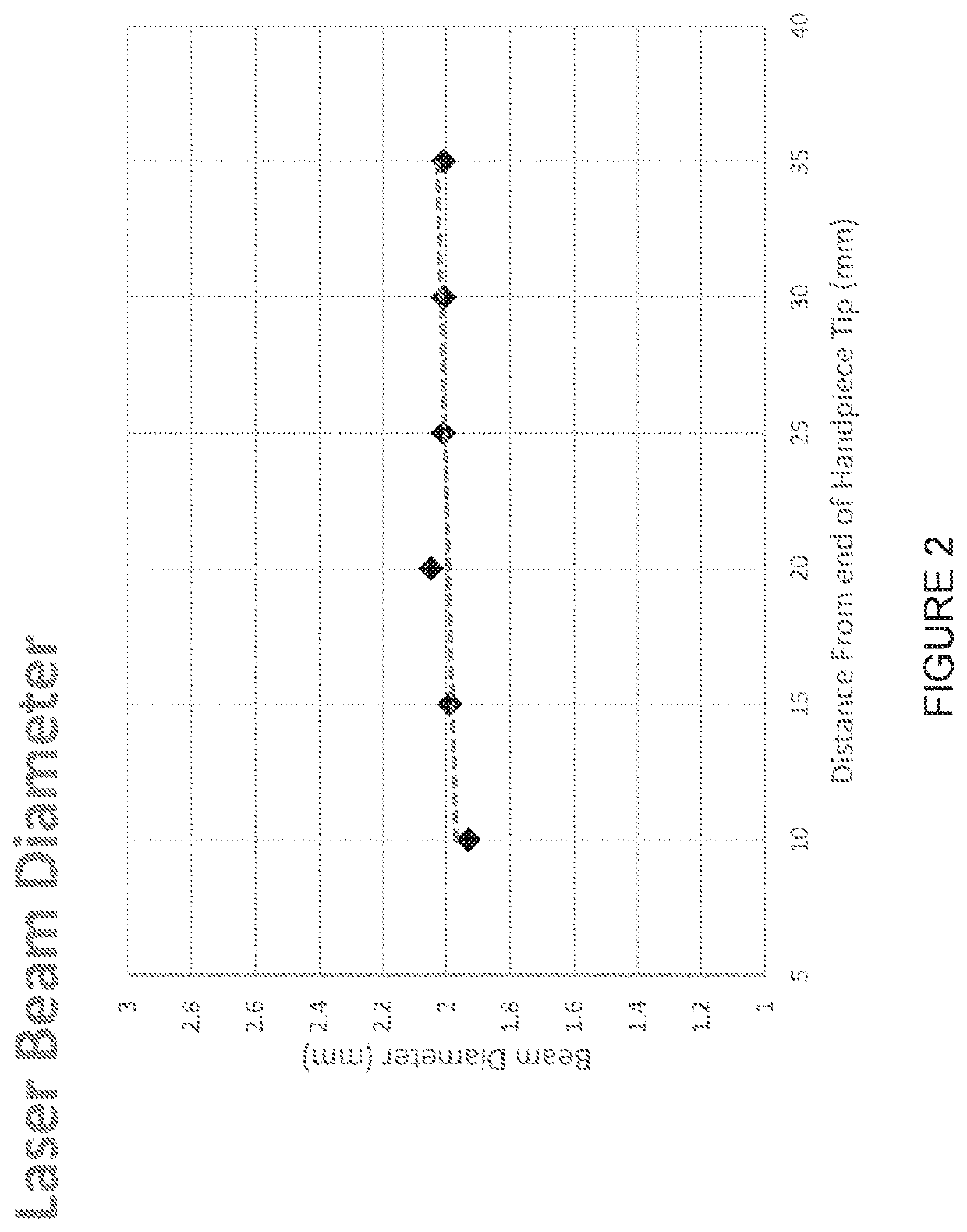

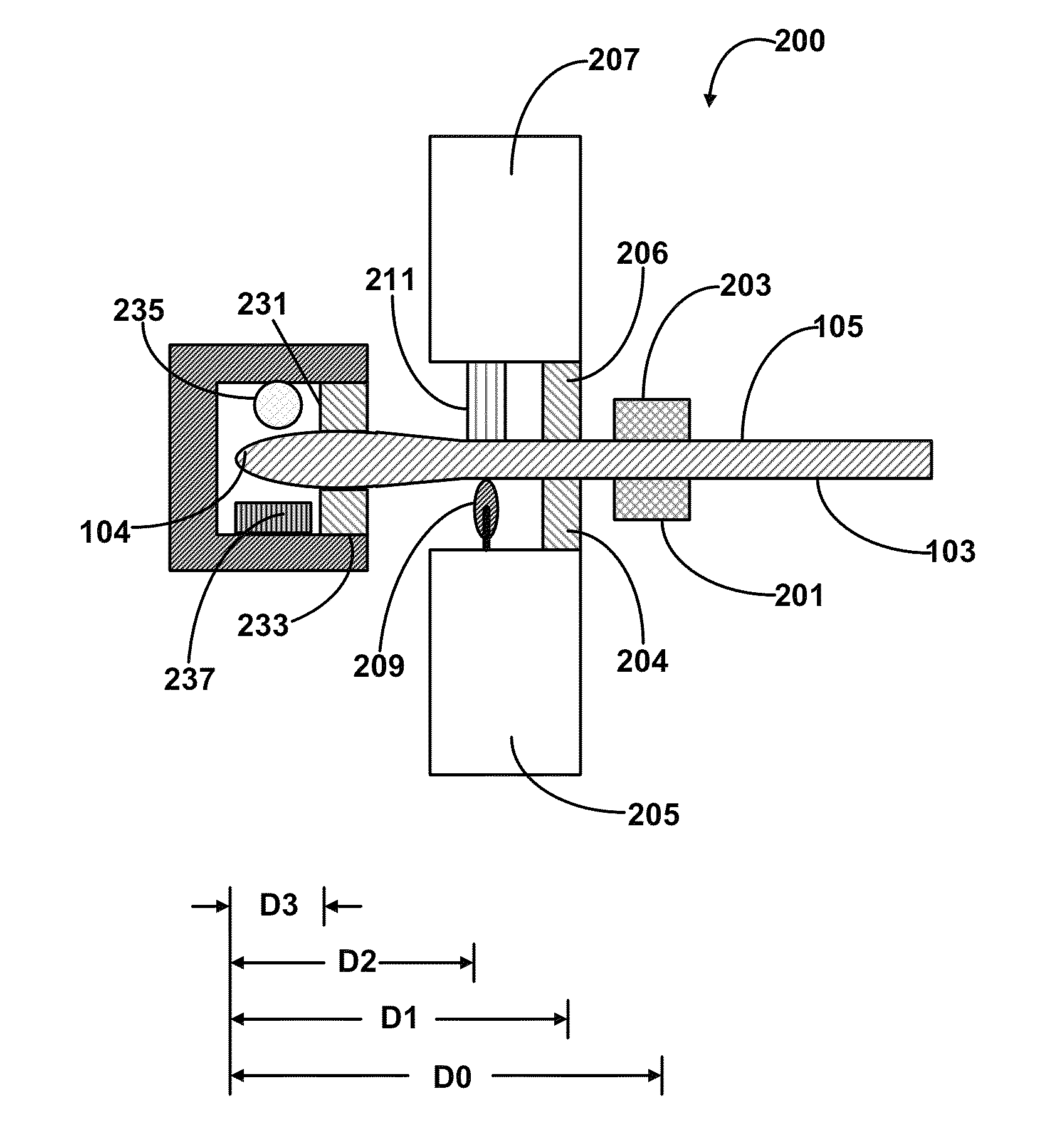

System and method for laser based treatment of soft tissue

ActiveUS10945790B2Large capacitySoft tissueLaser detailsSurgical instrument detailsOral treatmentNon ablative

The disclosed invention relates to an improved system and method for treatment of soft tissue, e.g., for treatment of a snoring condition. The system can include a laser source; a hand piece; and a device for directing radiation emitted by the laser source to a treatment area (e.g., an oral treatment area). In some cases, the handpiece can include an optical element (e.g., a lens) mounted within a replaceable cartridge and adapted to modulate a laser beam such that it is non-ablative, prior to its delivery to a treatment region. In various embodiments, the system includes a CO2 laser capable of performing treatment in a more efficient manner than conventional techniques.

Owner:CONVERGENT DENTAL INC

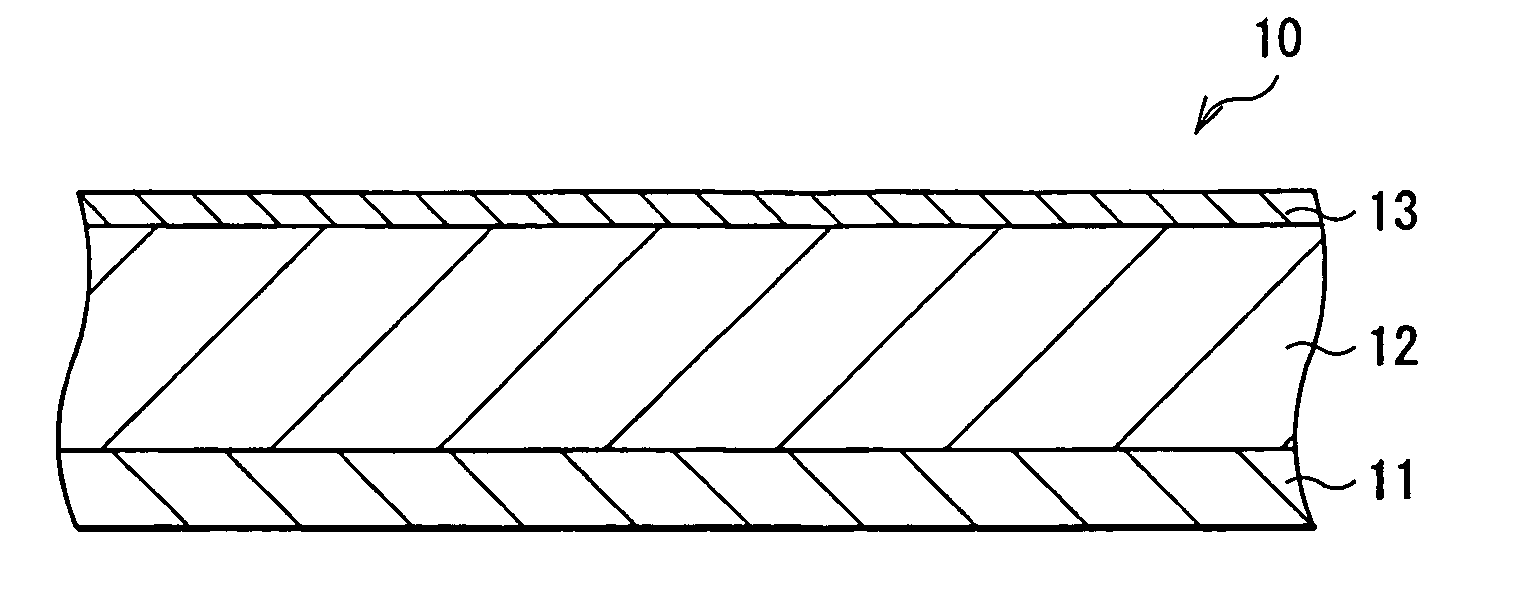

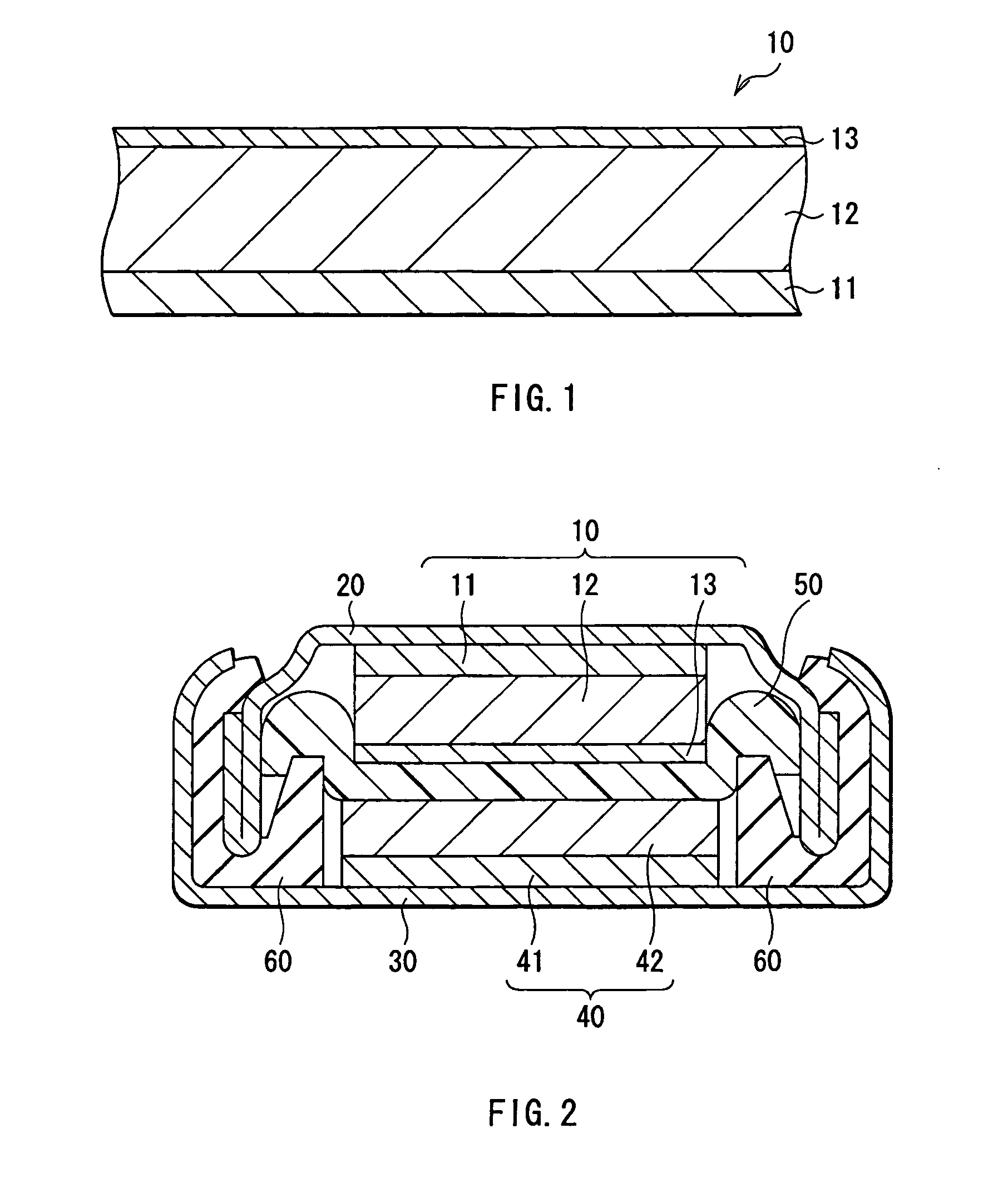

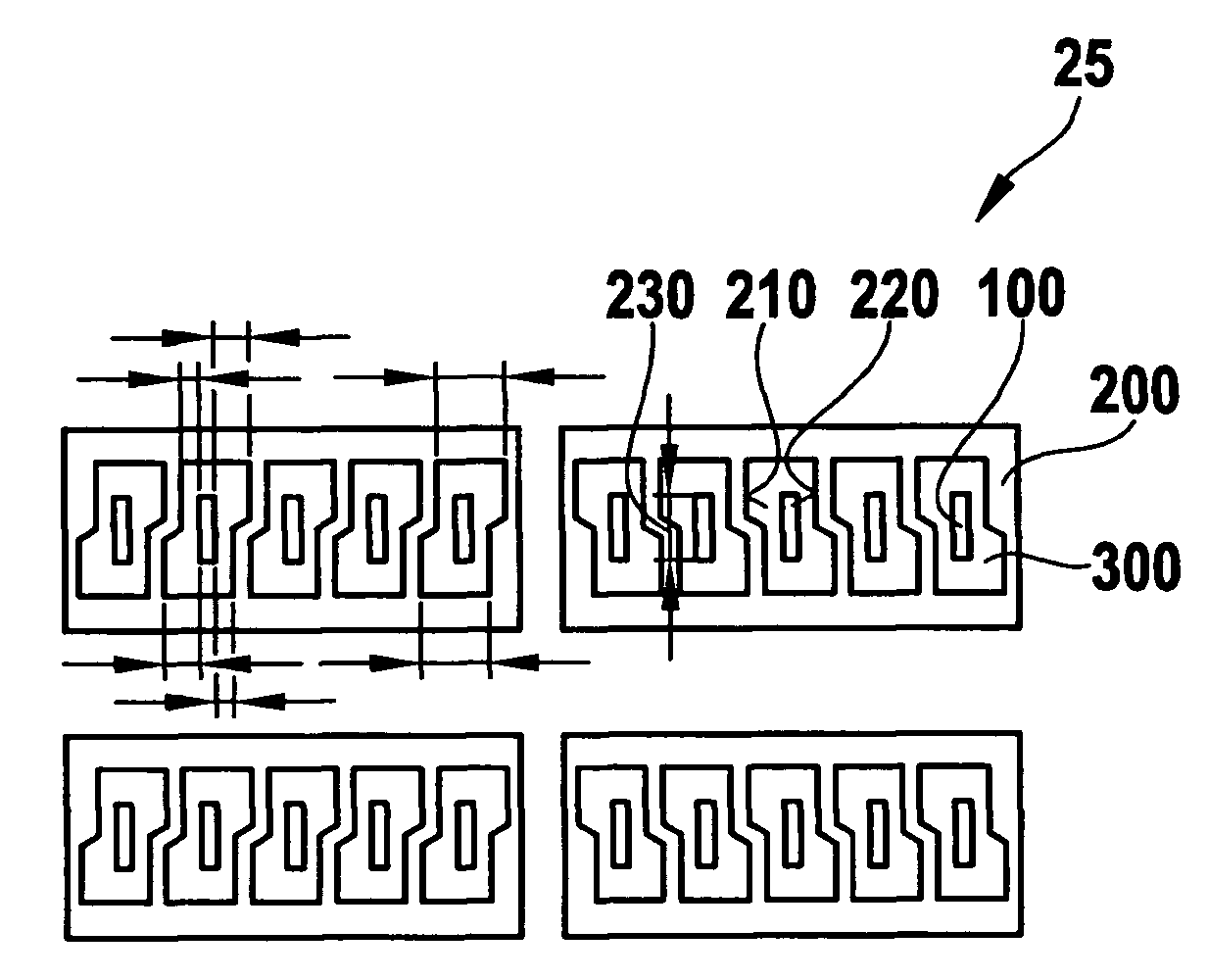

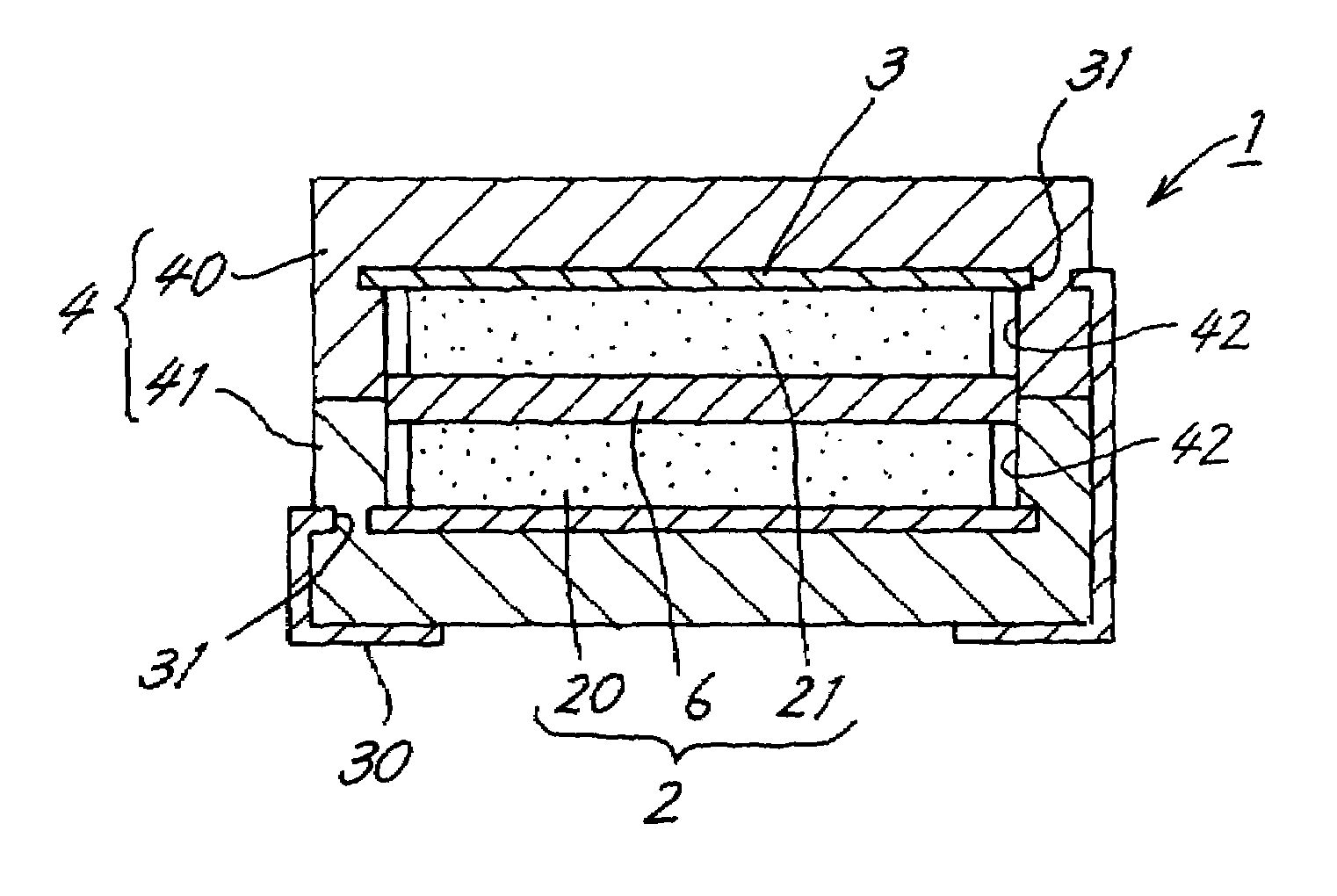

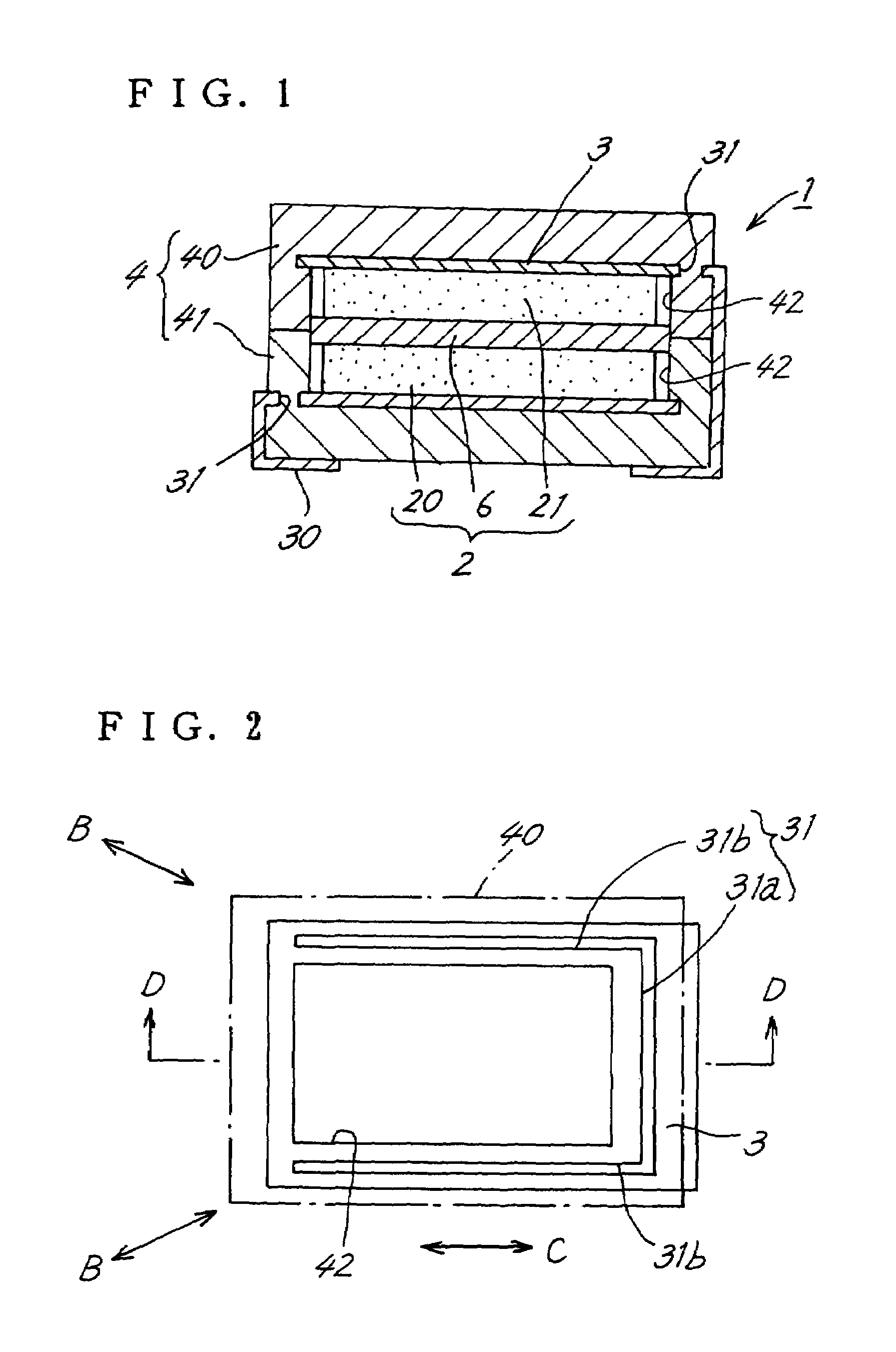

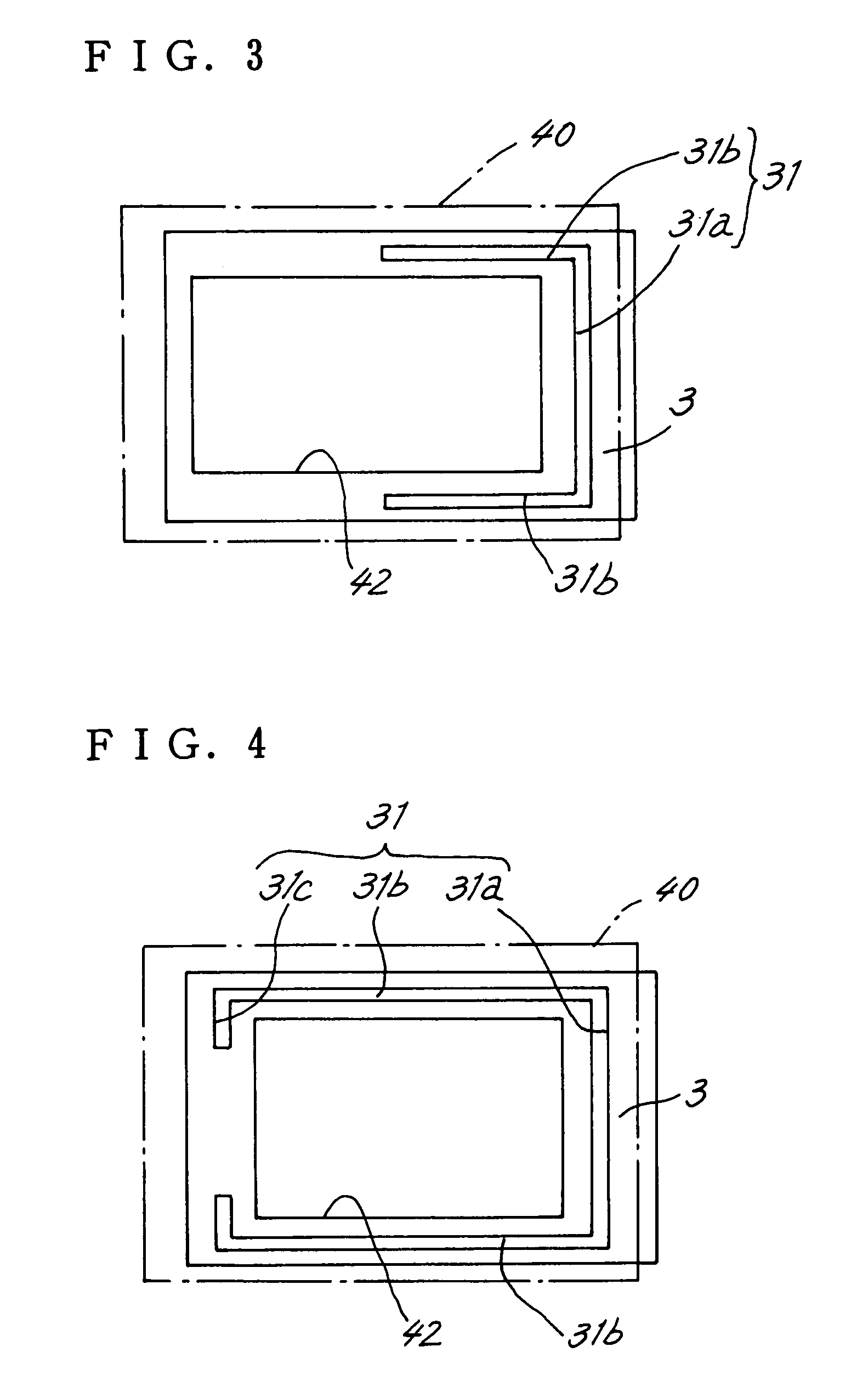

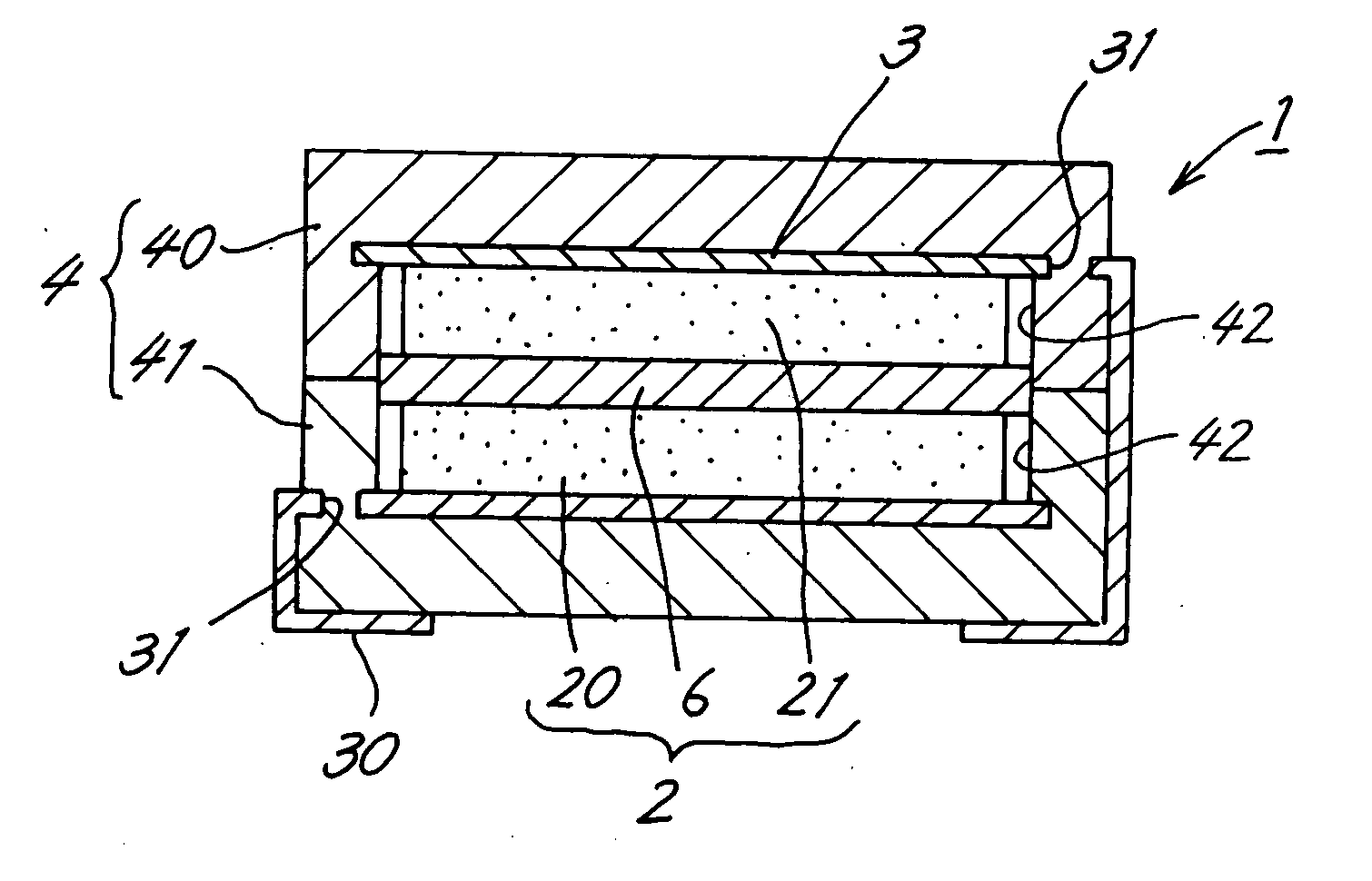

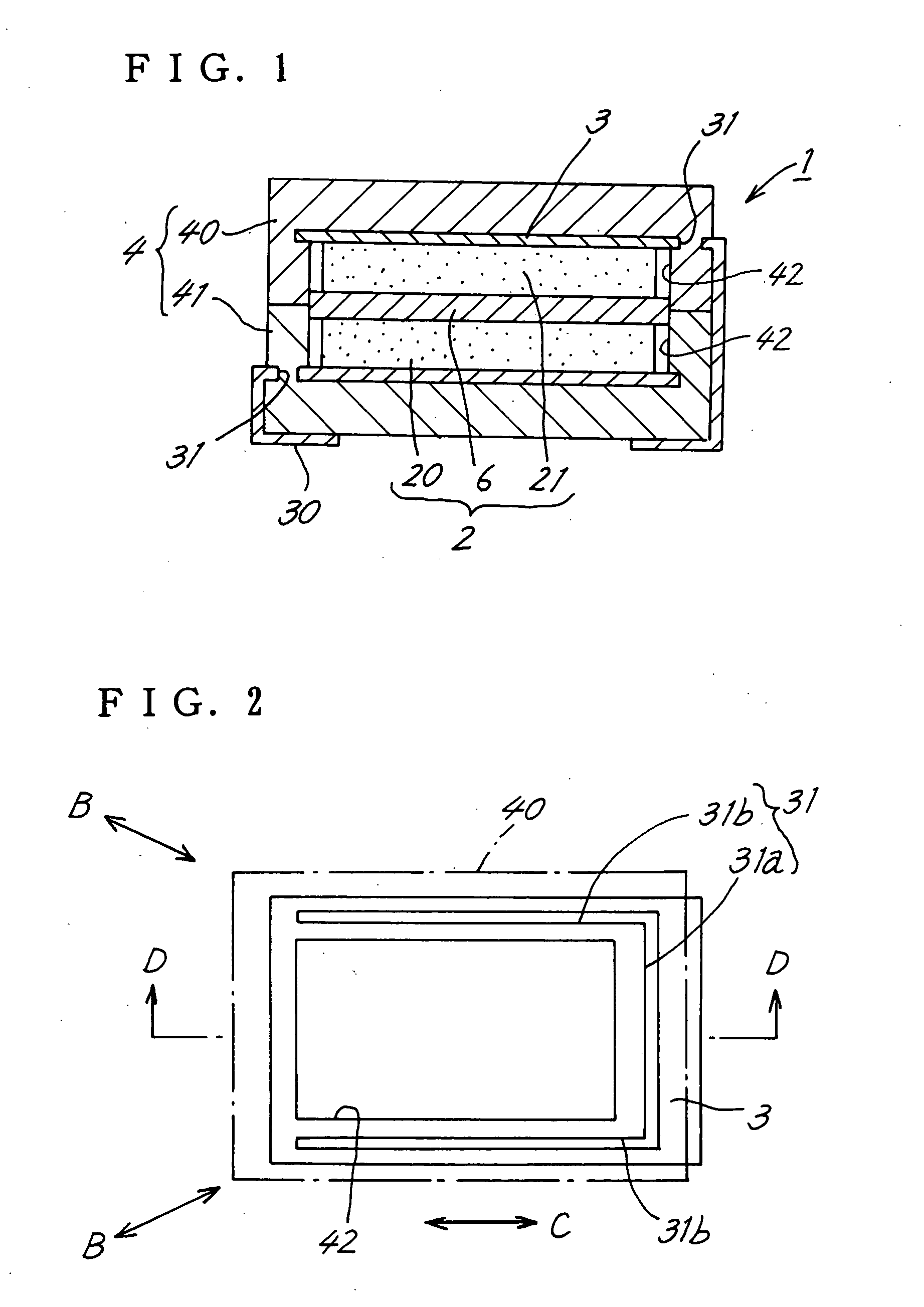

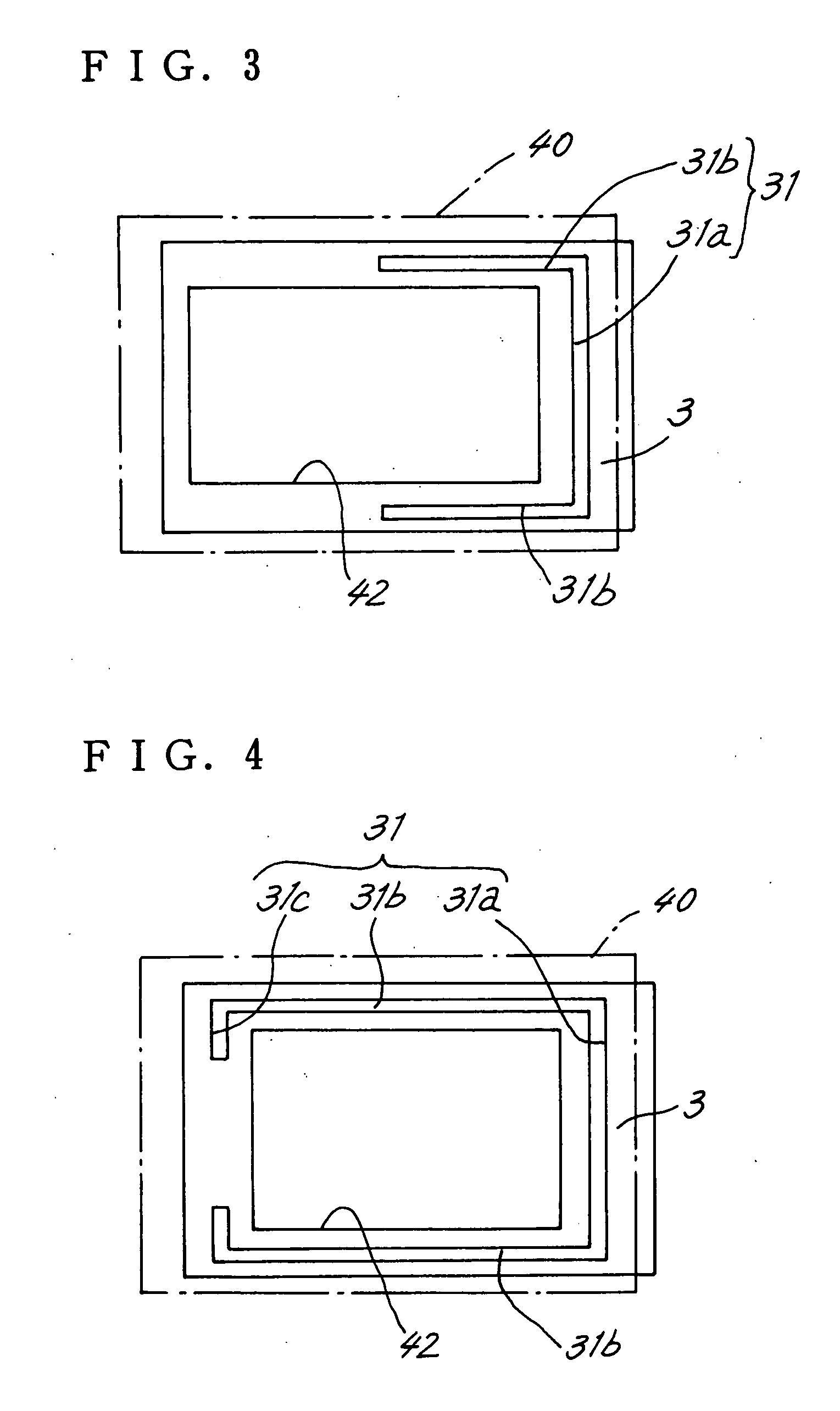

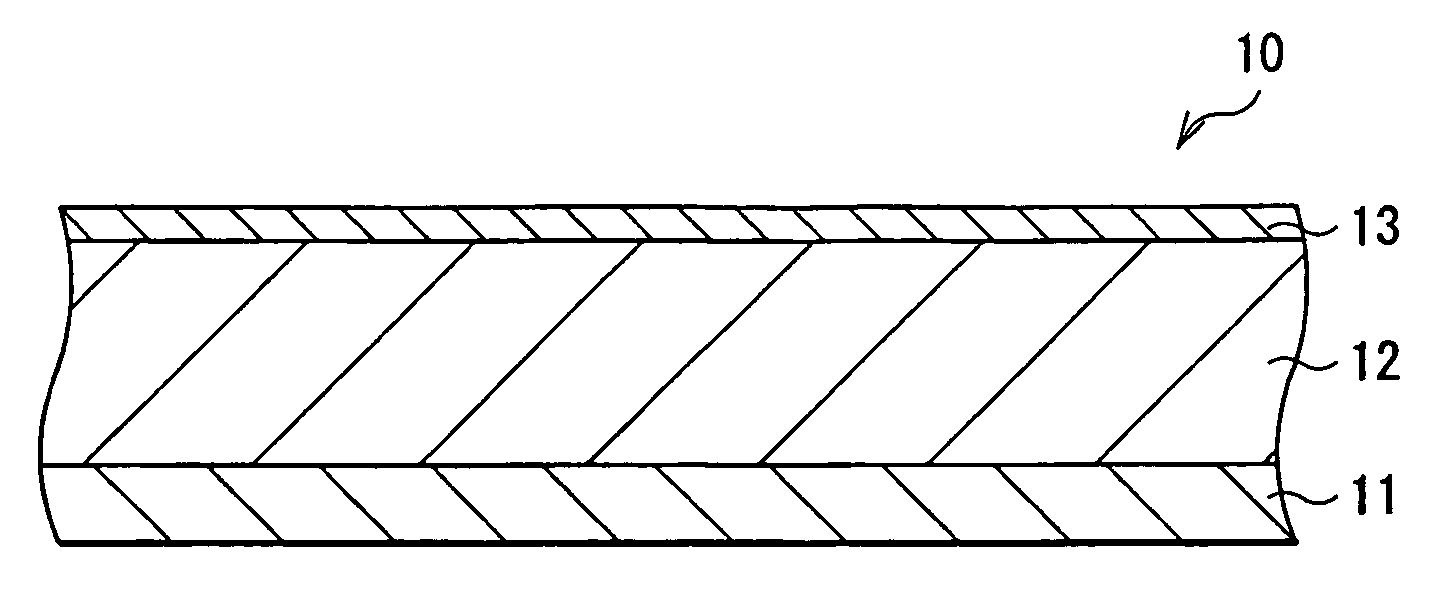

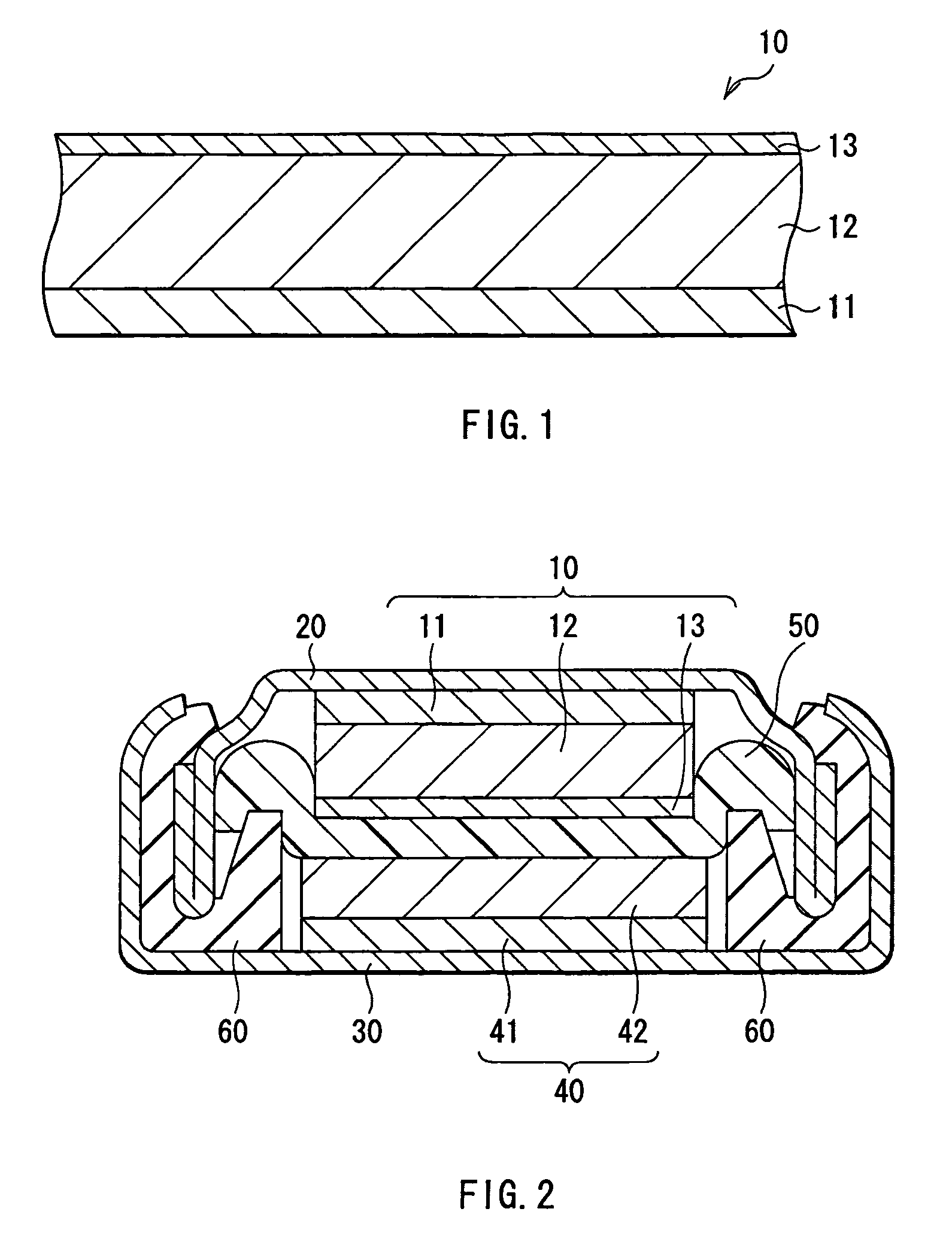

Electric double layer capacitor, electrolyte battery and method for manufacturing the same

InactiveUS7079376B2Improve adhesionLeaking and entry of moisture is preventedLiquid electrolytic capacitorsFinal product manufactureDiagonalEngineering

An electric double layer capacitor is provided with a cell, in which a pair of polarizable electrodes, which are impregnated with an electrolyte, are disposed in opposition on either side of a separator; wherein the polarizable electrodes are provided with collector electrodes, a peripheral portion of the cell is sealed by a sealing member composed of synthetic resin, and the sealing member is formed by abutting two case halves. A manufacturing method for the capacitor includes a process step of providing at least one long slit in the collector electrodes; a step of forming the case halves formed by insert molding on the collector electrodes and filling the slit, the case halves comprising a recess, one side of which extends in the lengthwise direction of the slit and, the cell being fitted into a portion inward from the slit; and a step of joining the case halves by abutting the case halves and applying ultrasonic vibration either in a perpendicular direction or a diagonal direction with respect to the lengthwise direction of the slit.

Owner:SANYO ELECTRIC CO LTD +1

Electric double layer capacitor, electrolyte battery and method for manufacturing the same

InactiveUS20050213284A1Improve adhesionPrevent leakageLiquid electrolytic capacitorsFinal product manufactureDiagonalEngineering

An electric double layer capacitor is provided with a cell, in which a pair of polarizable electrodes, which are impregnated with an electrolyte, are disposed in opposition on either side of a separator; wherein the polarizable electrodes are provided with collector electrodes, a peripheral portion of the cell is sealed by a sealing member composed of synthetic resin, and the sealing member is formed by abutting two case halves. A manufacturing method for the capacitor includes a process step of providing at least one long slit in the collector electrodes; a step of forming the case halves formed by insert molding on the collector electrodes and filling the slit, the case halves comprising a recess, one side of which extends in the lengthwise direction of the slit and, the cell being fitted into a portion inward from the slit; and a step of joining the case halves by abutting the case halves and applying ultrasonic vibration either in a perpendicular direction or a diagonal direction with respect to the lengthwise direction of the slit.

Owner:SANYO ELECTRIC CO LTD +1

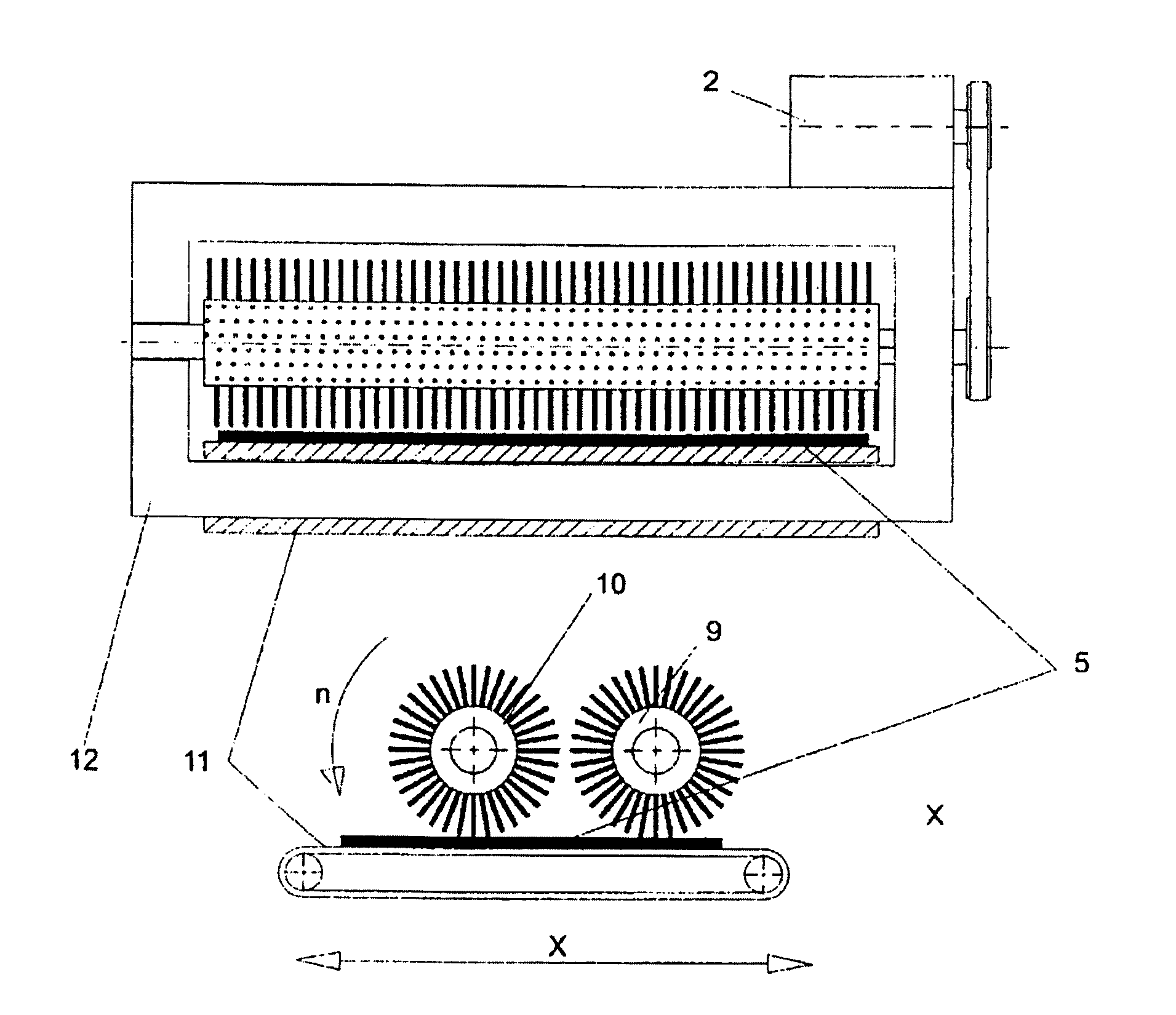

Method of Modifying Flat Glass Surface and Apparatus for Carrying Out the Method

InactiveUS20120108148A1Improve functional propertiesGreat dispersion of lightPolishing machinesRevolution surface grinding machinesFlat glassAbrasive

The method of modifying the flat glass surface is based on that the surface of a glass is worked by abrasive grains of synthetic diamond which are situated in the mass of plastic threads that are a part of a rotating brush. The glass is first tarnished using brushes with rougher abrasive grains of synthetic diamond and then tarnishing is finished using brushes with smaller abrasive grains. With the brushes, it is also possible to modify already sandblasted glass surface. The apparatus for modifying glass surface is made up of at least one rotating brush (9, 10) that is bedded in static or moveable disposition above the glass plate (5) which is to be modified, while the brush (9,10) has abrasive plastic threads (3) embedded with abrasive grains of synthetic diamond.

Owner:ING ZBYSEK PANCHARTEK

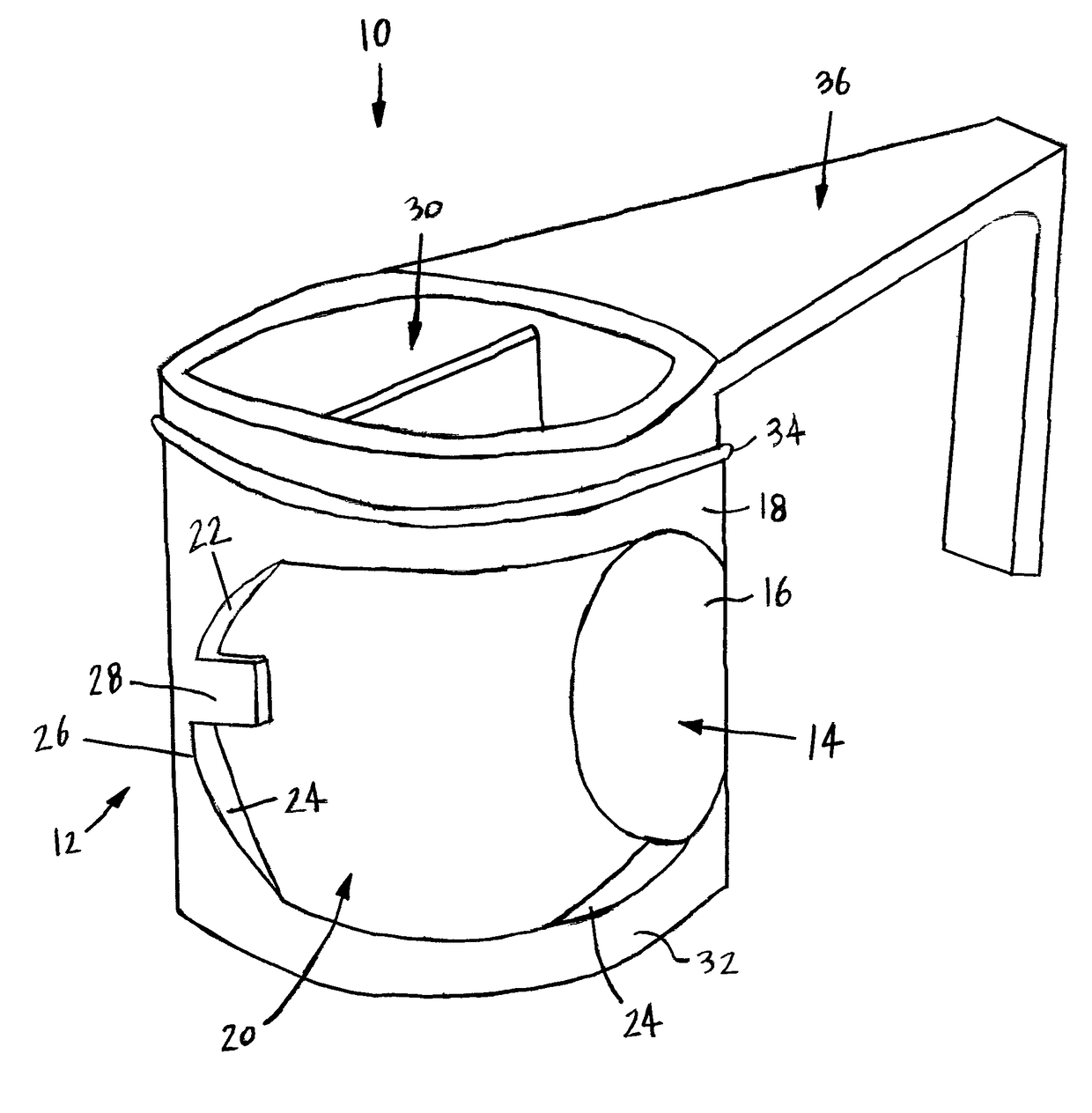

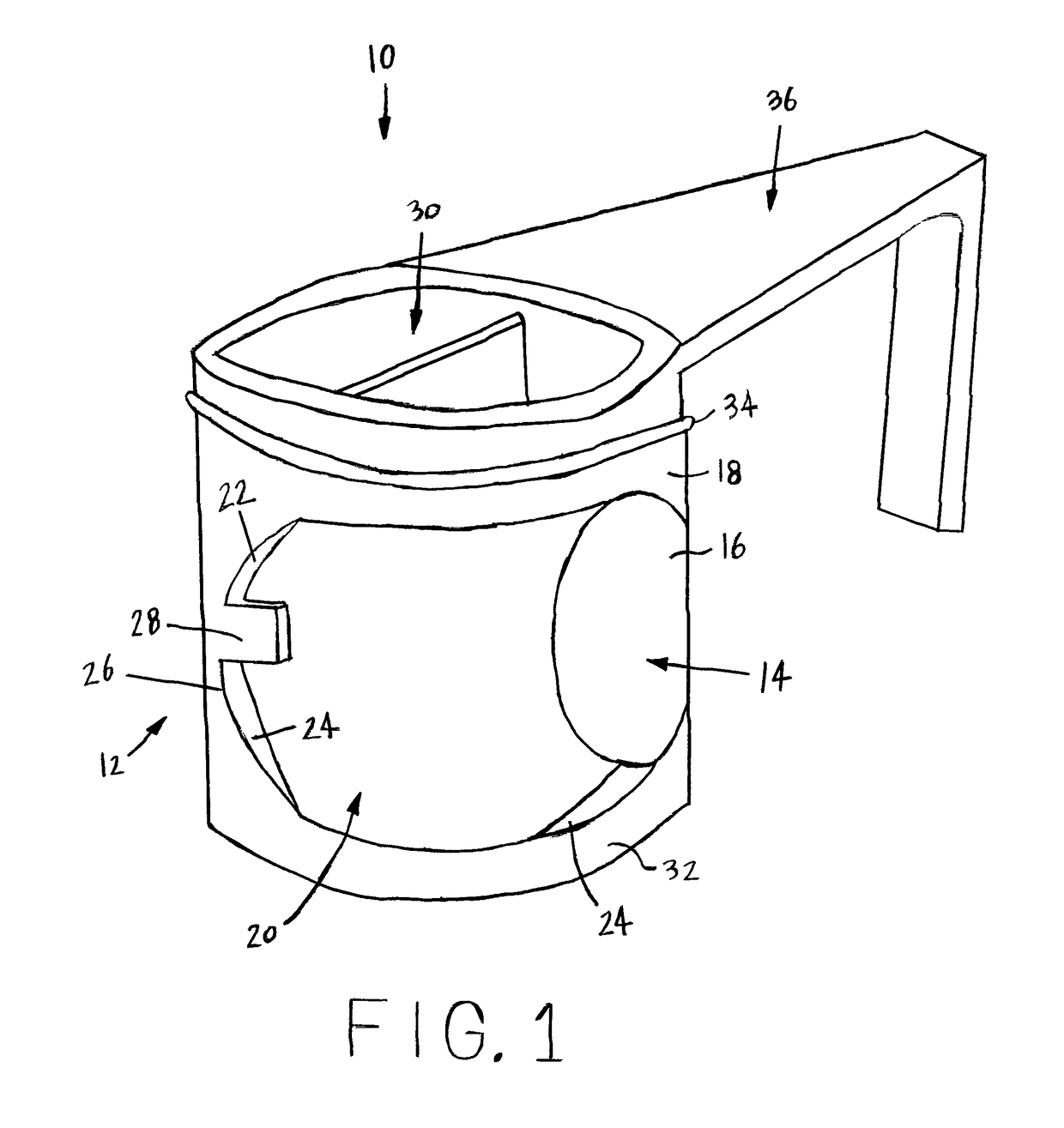

Dental valve device having a disposable turret

ActiveUS9980790B2Easy to install into and removeLess surfaceSaliva removersBoring toolsEngineeringVALVE PORT

A dental valve device having a disposable turret is disclosed having a valve body having a tip receiving end, a hose receiving end, a lumen formed between the tip receiving end and the hose receiving end, an opening formed in the valve body, and a rotatable valve sealing body adapted to being inserted into the opening, the rotatable valve sealing body having a bore for alignment with the lumen formed between the tip receiving end and the hose receiving end, the bore having a tip receiving end opening and a hose receiving end opening, the rotatable valve sealing body having an outer surface having an indentation formed in the outer surface adjacent to the tip receiving end opening with the indentation having an upper ramp portion, a lower ramp portion, and an end having a tab portion.

Owner:STOMA VENTURES

Anode and battery

ActiveUS9425441B2Improving impedanceSuppress mutationElectrode thermal treatmentFinal product manufactureLithium carbonateAlloy

Provided are an anode capable of preventing an increase in impedance and variations in characteristics and a battery using the anode. An anode active material layer includes at least one kind selected from the group consisting of simple substances, alloys and compounds of silicon and the like capable of forming an alloy with Li. The anode active material layer is formed by a vapor-phase deposition method or the like, and is alloyed with an anode current collector. A coating including lithium carbonate is formed on at least a part of a surface of the anode current collector. Thereby, an increase in impedance can be prevented. Moreover, the anode is less subject to an influence by a difference in a handling environment or storage conditions, so variations in impedance can be prevented.

Owner:MURATA MFG CO LTD

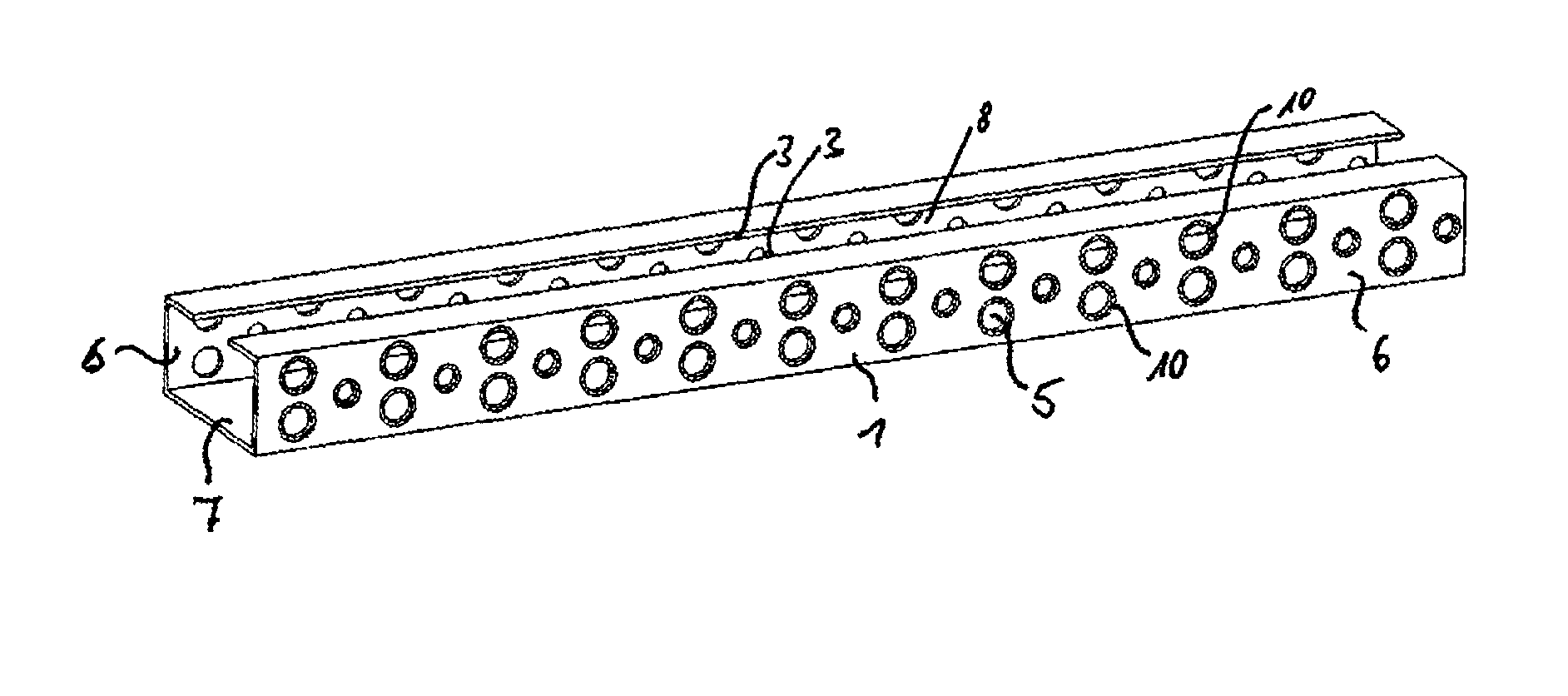

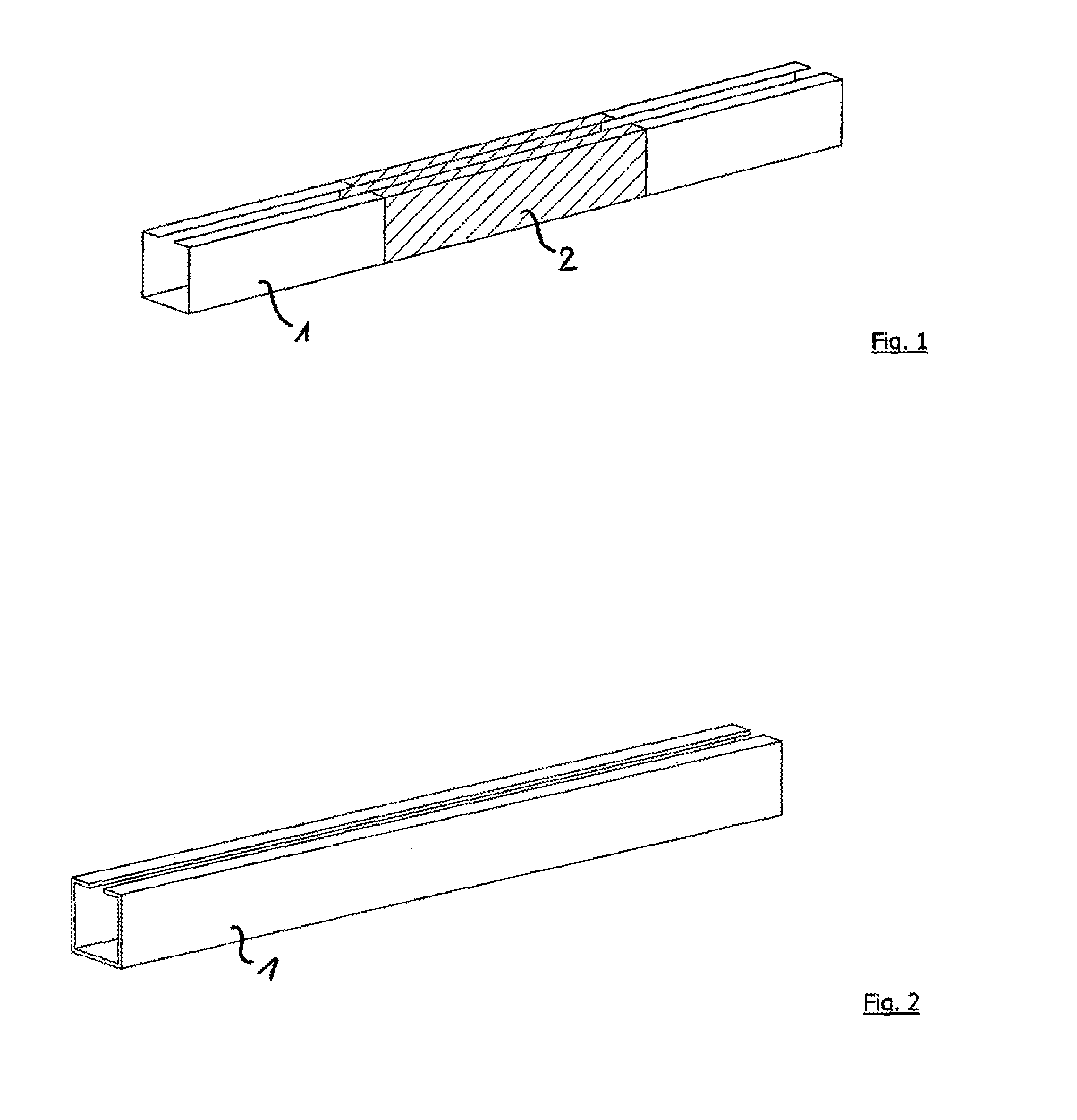

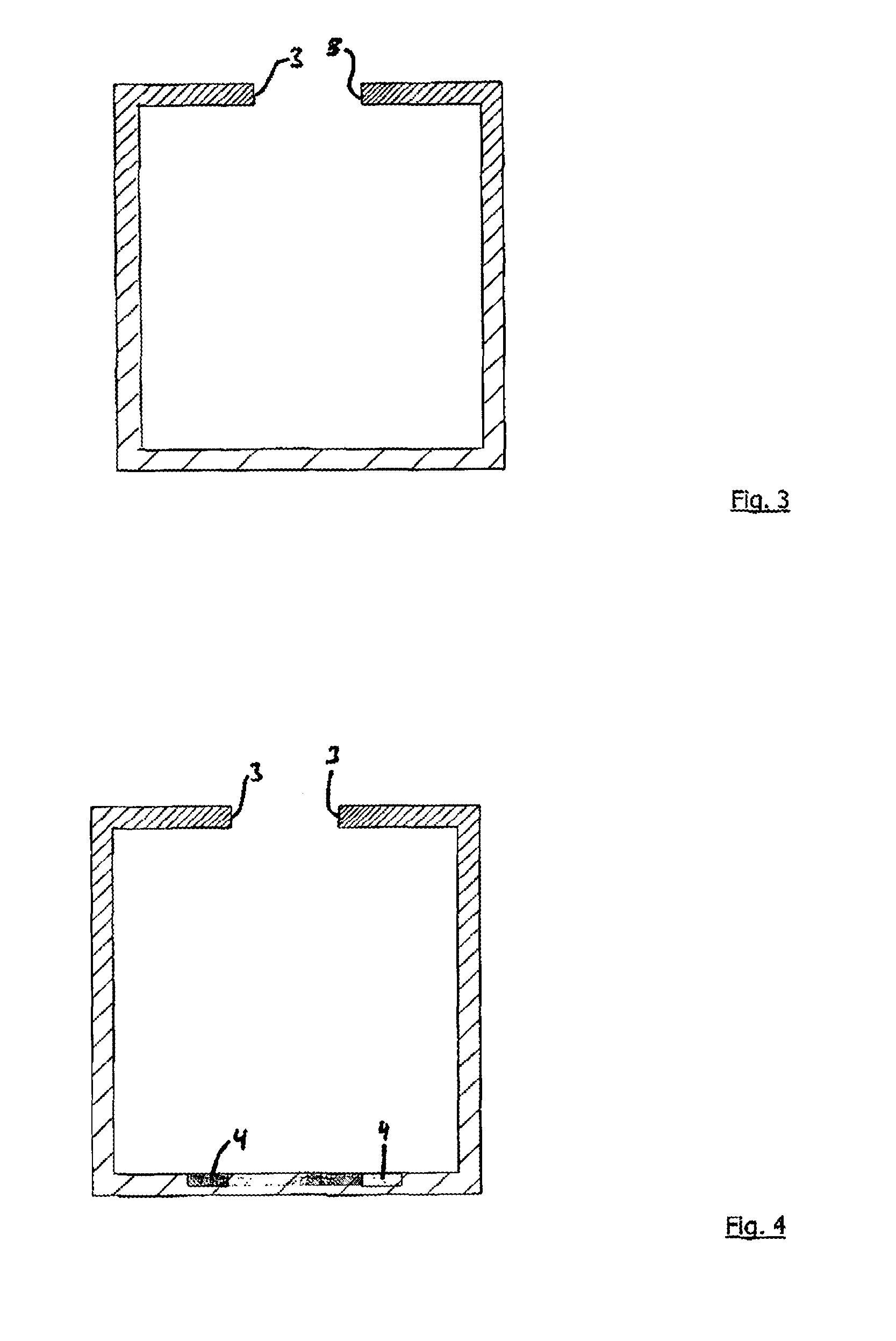

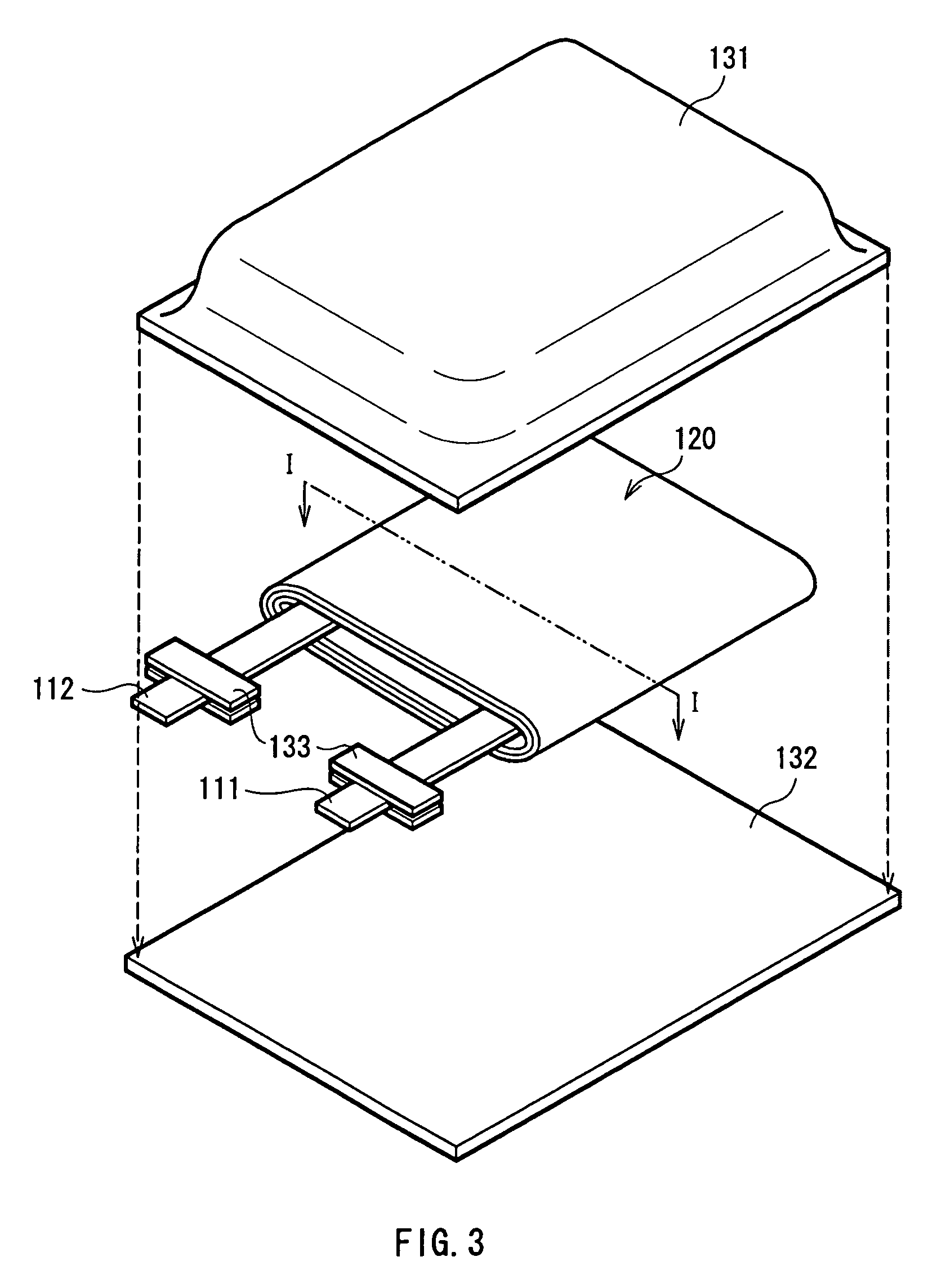

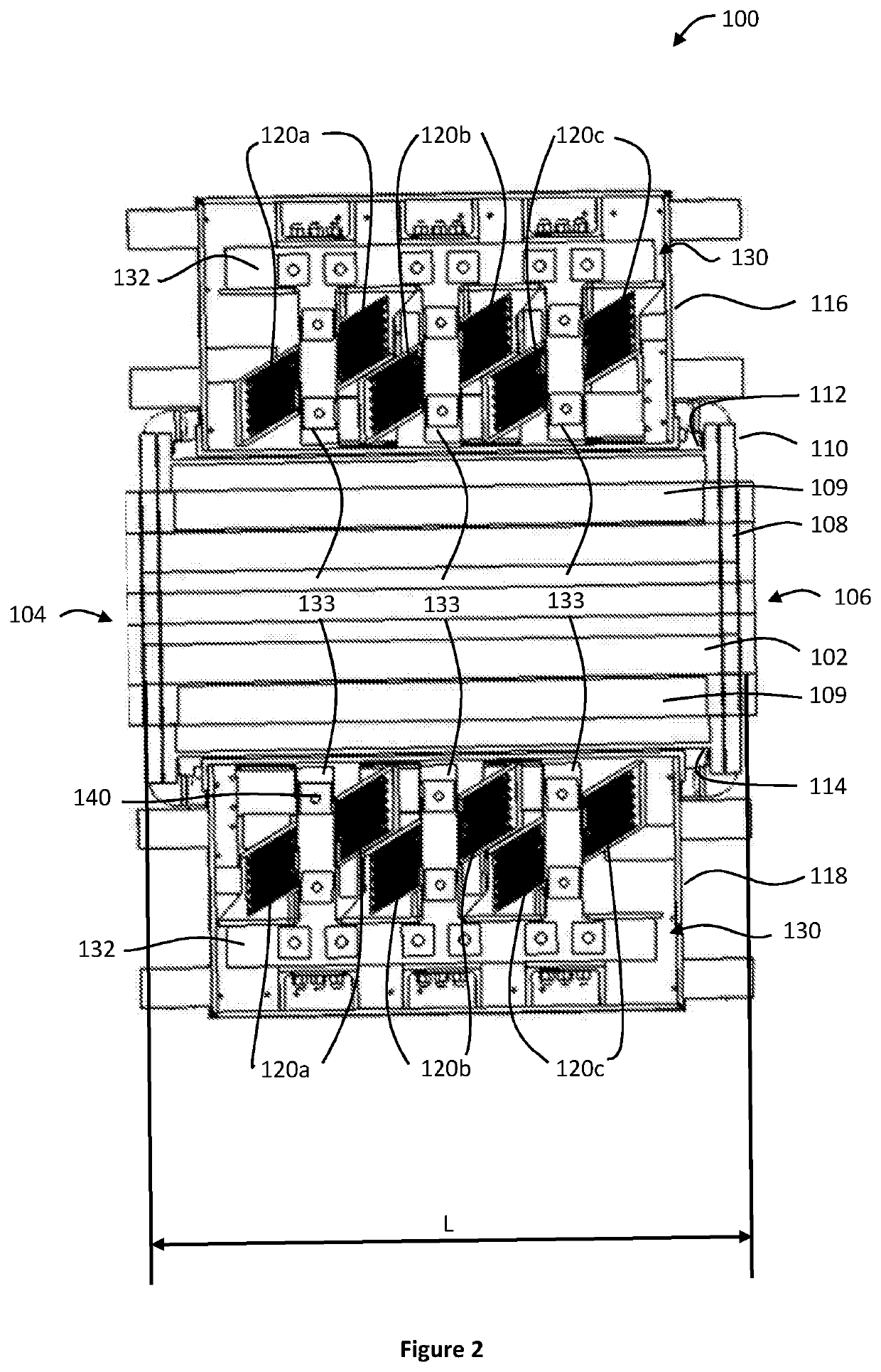

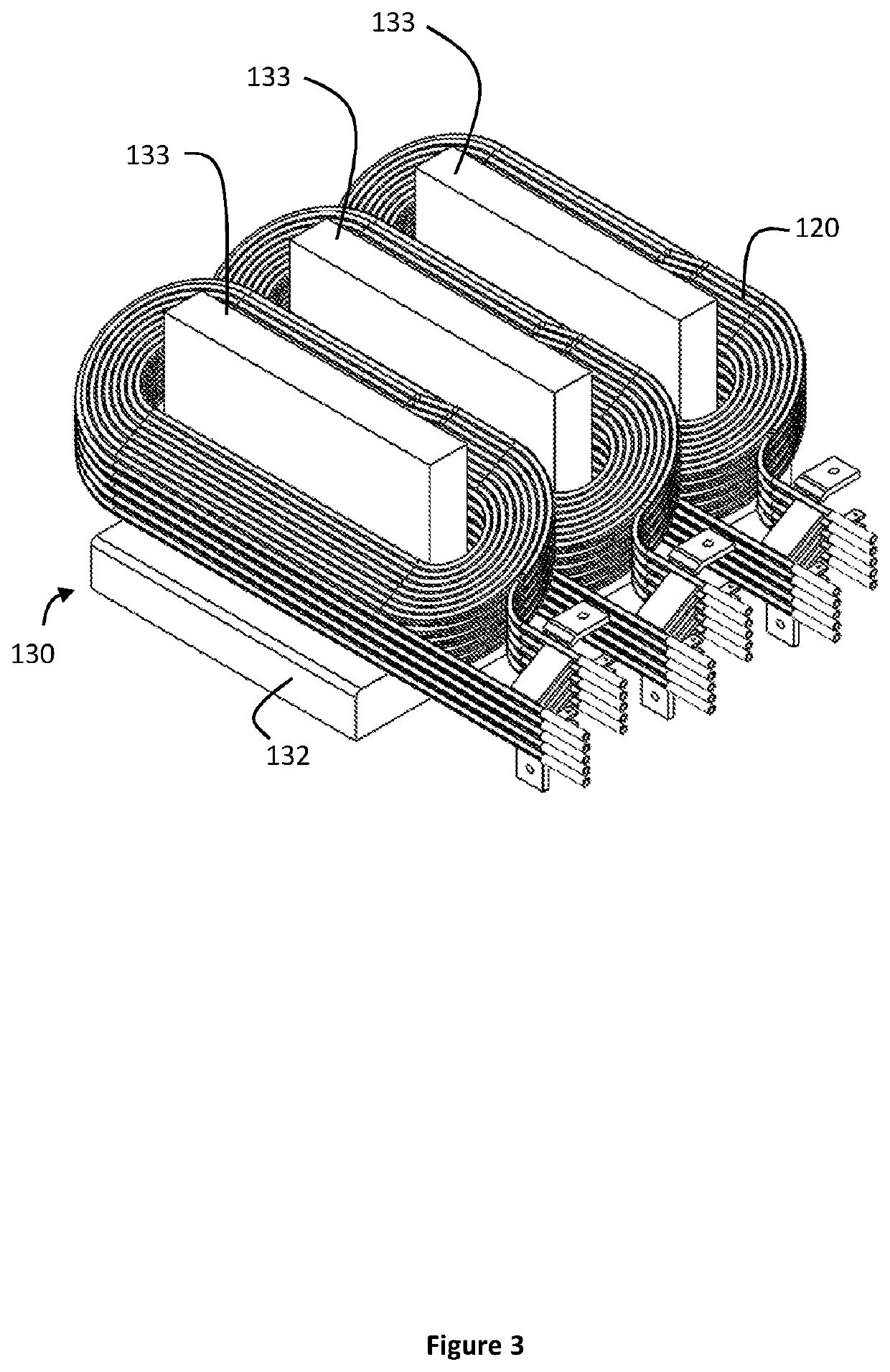

Electromagnetic device and system for pumping, circulating or transferring non-ferrous molten metal

PendingUS20220143688A1Maintenance quicker and moreSafe to touchMolten metal supplying equipmentsDynamo-electric machinesEngineeringInductor

An electromagnetic device for pumping, circulating or transferring non-ferrous molten metal has a duct made of a refractory material with a first aperture at a first end of the duct and a second aperture at a second end of the duct. The duct conveys a body of non-ferrous molten metal between the first and second apertures. The duct encloses the body of non-ferrous molten metal between the first and second apertures. The duct has opposing first and second external side surfaces. A first inductor assembly extends adjacent to the first side surface. The first inductor assembly comprises a plurality of inductors arranged along a length of the duct adjacent to the first side surface. An electronic circuit generates direct current pulses that energise each inductor of the plurality of inductors in a sequence, so as to generate a moving magnetic field within the body of non-ferrous molten metal which propels the body of non-ferrous molten metal along the duct.

Owner:EMP TECH

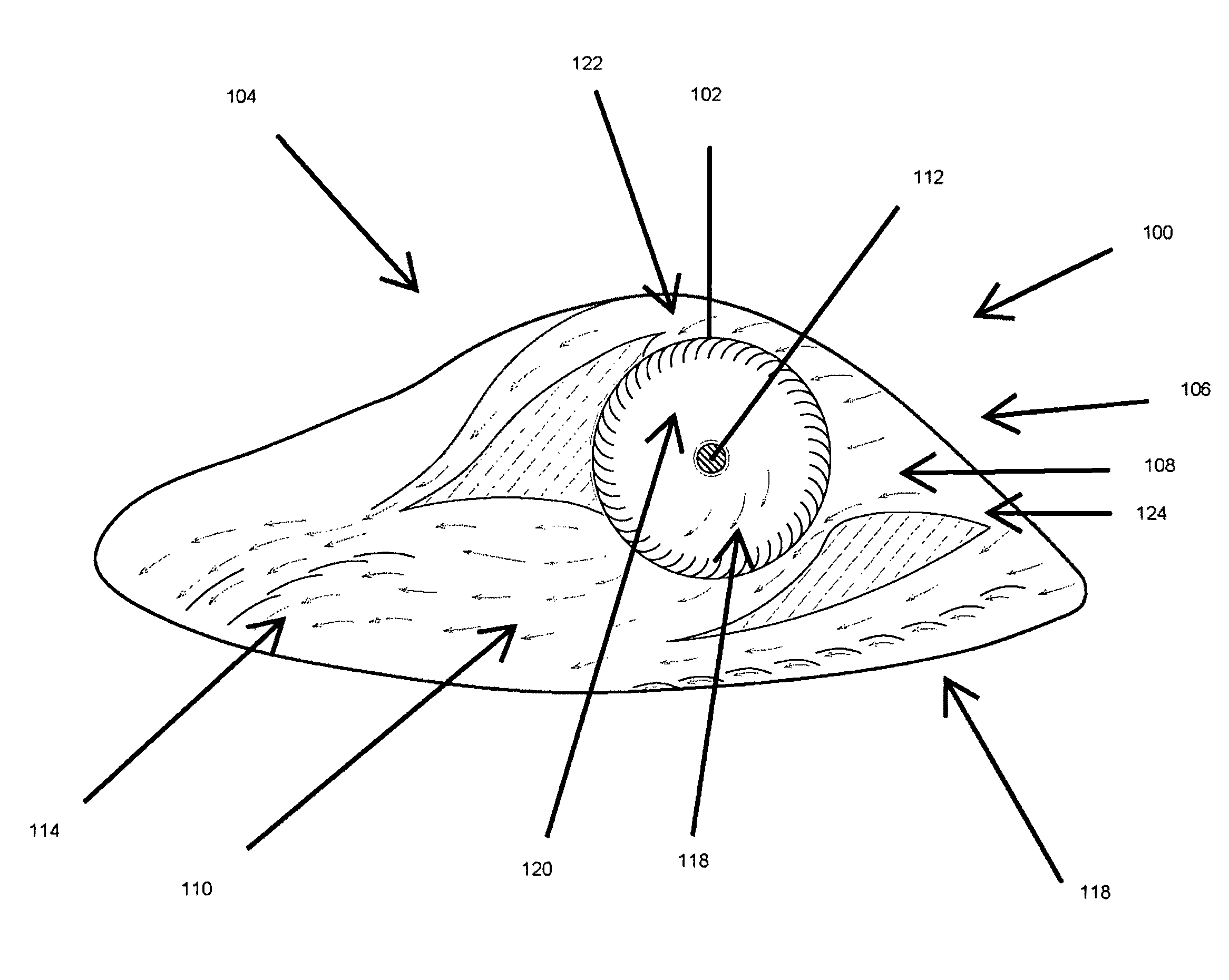

Scented wafer

ActiveUS20160206770A9Compact structureReduce releaseTobacco devicesGaseous substancesAromatherapyFiber

A scented wafer having a body formed of a heat resistant fibrous material having a predetermined porosity resulting from a selected denier and length of fibers. A scented material is impregnated into the body material and is constructed to melt and release a scent when exposed to heat at a predetermined temperature for aromatherapy, insect repellant, wild life attractant, medicinal use, deodorant and odor control, perfume release, or any other desired or suitable purpose. The body material does not melt at the predetermined temperature.

Owner:AMERICAN FELT & FILTER

Scented wafer

ActiveUS20160022859A1Compact structureReduce releaseTobacco devicesGaseous substancesFlavorInsect repellants

A scented wafer having a body formed of a heat resistant fibrous material having a predetermined porosity resulting from a selected denier and length of fibers. A scented material is impregnated into the body material and is constructed to melt and release a scent when exposed to heat at a predetermined temperature for aromatherapy, insect repellant, wild life attractant, medicinal use, deodorant and odor control, perfume release, or any other desired or suitable purpose. The body material does not melt at the predetermined temperature.

Owner:AMERICAN FELT & FILTER

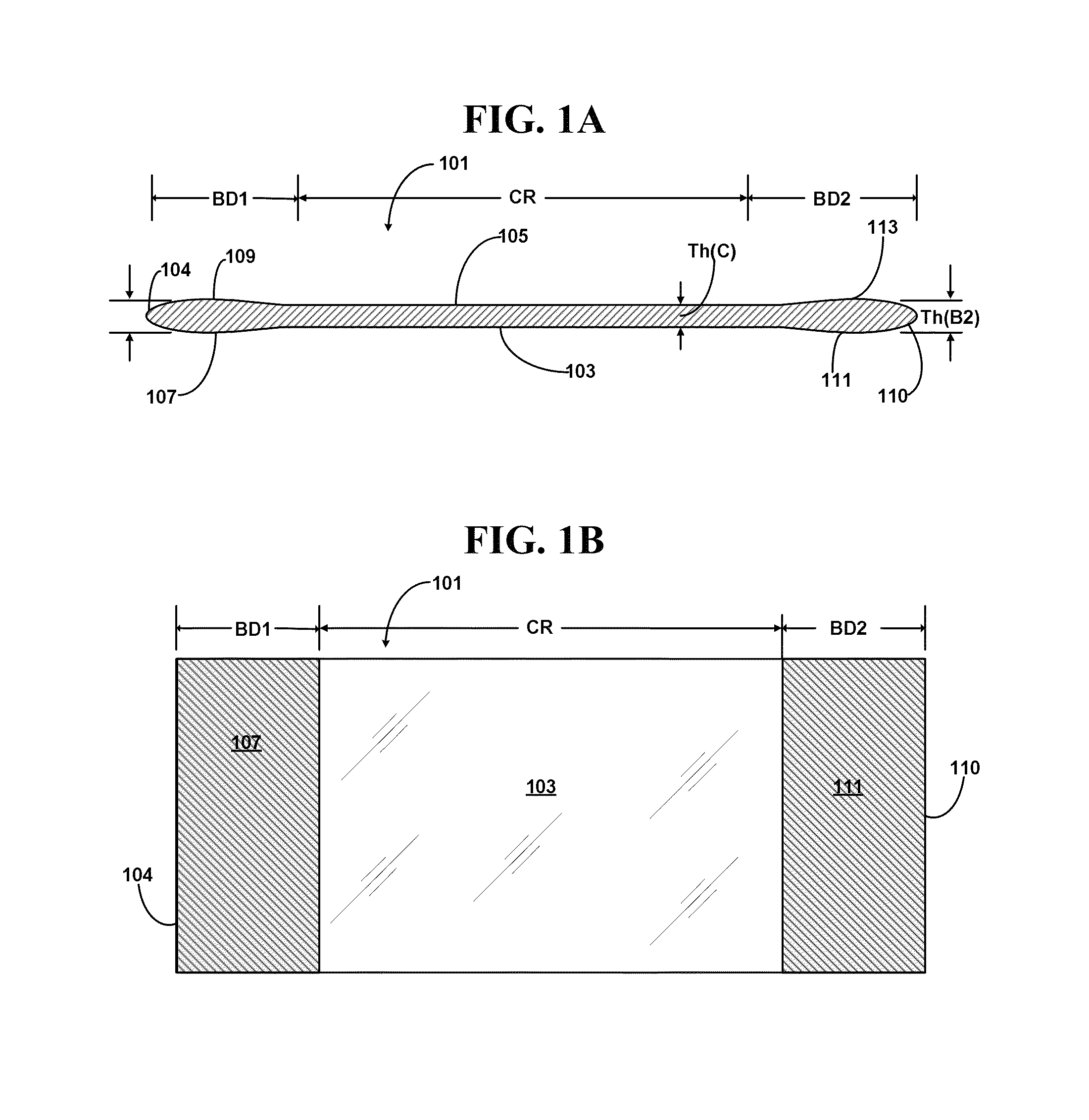

Method and apparatus for removing peripheral portion of a glass sheet

InactiveUS8756817B2Reduce warpageEasy to participateOpening closed containersBottle/container closureCompletion timeEngineering

Process for removing peripheral portions such as bead regions of a glass sheet including a step of pushing the glass sheet in the peripheral portion using a pushing mechanism such as a pushing bar, and corresponding apparatus. As a result of the use of the pushing mechanism, the engagement completion time for suction cups, if used, are reduced significantly. A process without using suction cups is enabled with enhanced yield. The increased process stability and enlarged process window are particularly advantageous for processing glass sheets having high flexibility.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com