Preparation method of asymmetric supercapacitor of water system

A supercapacitor, asymmetric technology, applied in the direction of hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem of low energy density, achieve high energy density, avoid dead volume, and increase the effect of active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

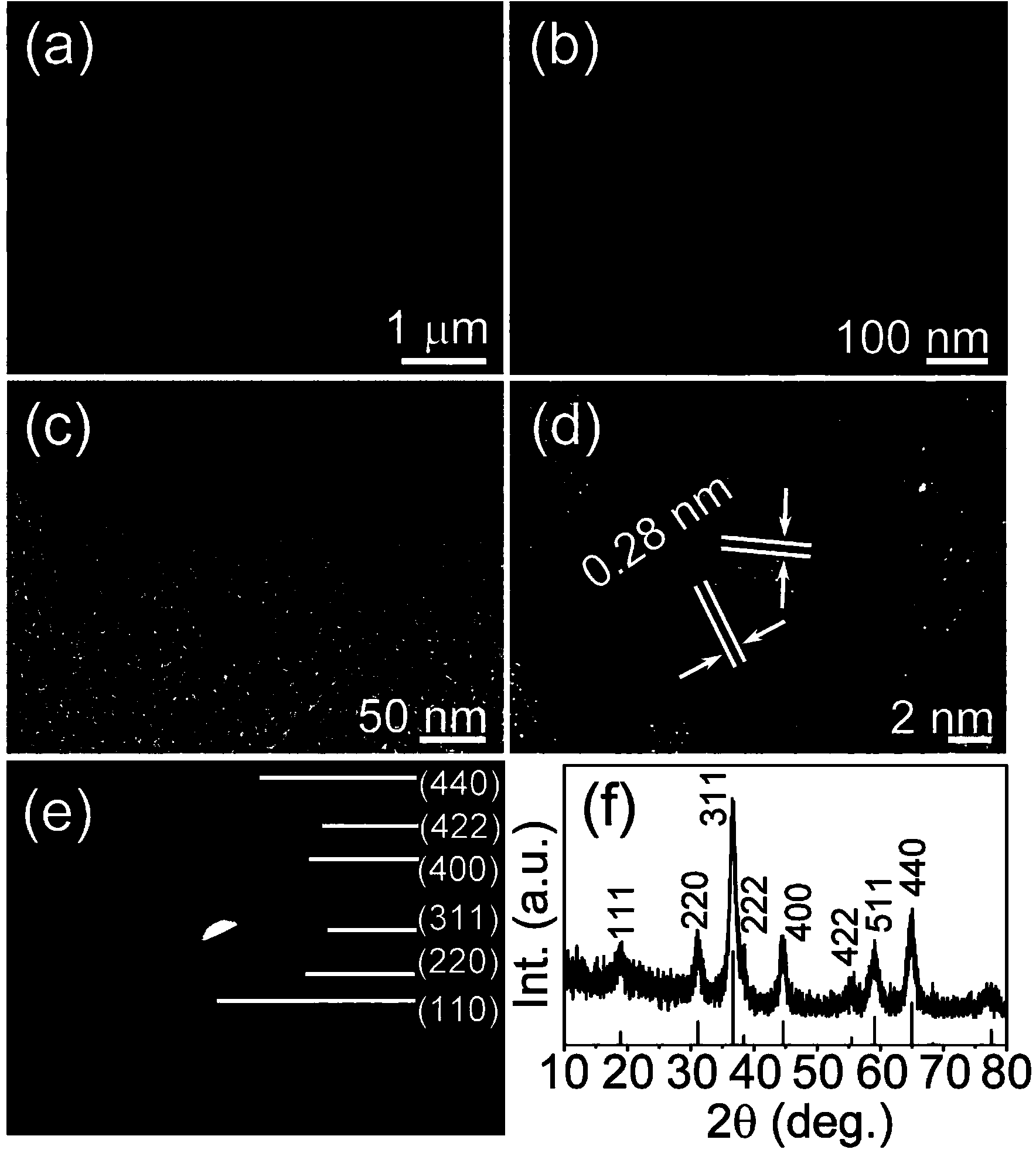

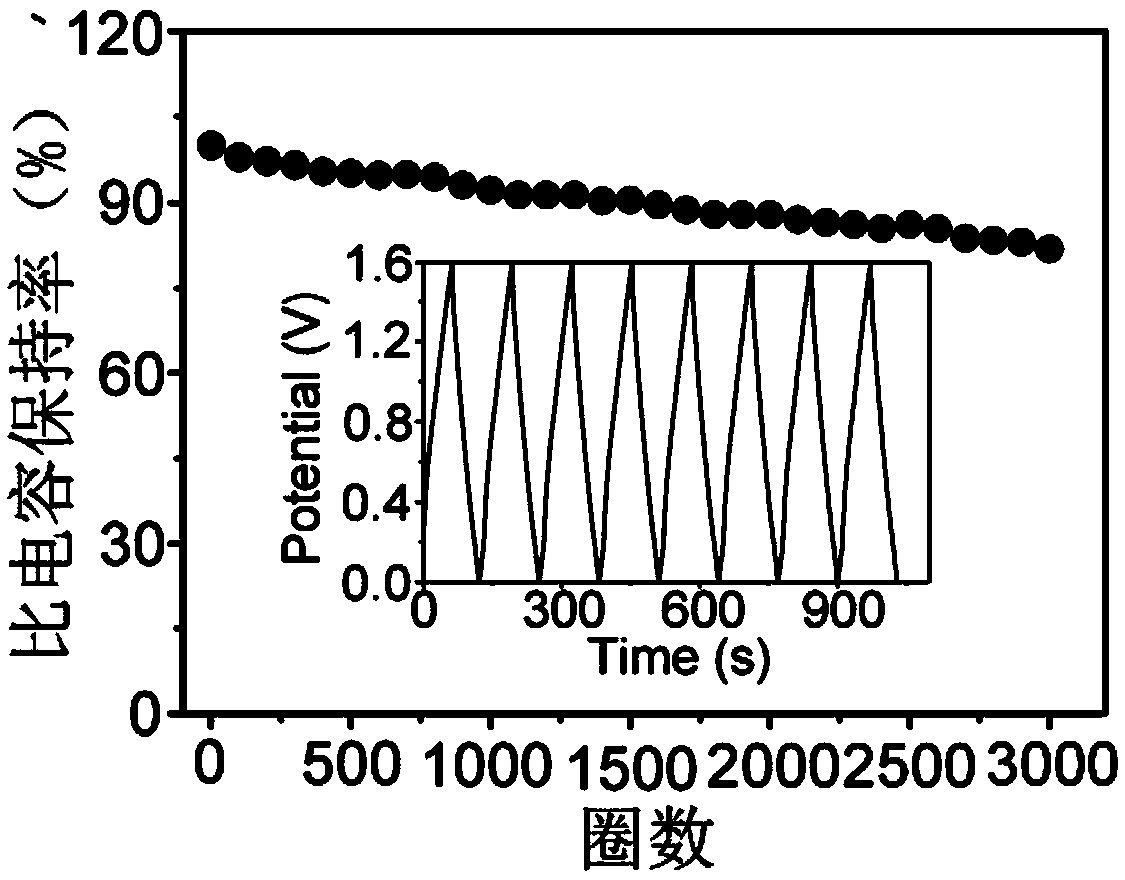

[0033] A kind of NiCo 2 o 4 co x Ni 1-x (OH) 2 / / The preparation of CMK-3 water-based asymmetric supercapacitor, the characteristic steps are: 1) NiCo 2 o 4 co x Ni 1-x (OH) 2 Preparation of:

[0034] A Put the foam nickel of appropriate size into a solution containing 1M hydrochloric acid for ultrasonic cleaning, the purpose is to remove the nickel oxide on the surface of the foam nickel.

[0035] B takes by weighing raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.29g, cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) 0.58g and ammonium nitrate (NH 4 NO 3 ) was dissolved in water and stirred to obtain a mixed solution in which Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O molar ratio is 1:2, ammonium nitrate is 0.08g.

[0036] C. Place the above-mentioned cleaned foamed nickel in the mixed solution of step B, heat to 70° C., and then use the electrochemical deposition method to deposit under the condition of -1V constant voltage for 5 minut...

Embodiment 2

[0044] A kind of NiCo 2 o 4 co x Ni 1-x (OH) 2 / / The preparation of CMK-3 water-based asymmetric supercapacitor, the characteristic steps are: 3) NiCo 2 o 4 co x Ni 1-x (OH) 2 Preparation of:

[0045] A Put the foam nickel of appropriate size into a solution containing 1M hydrochloric acid for ultrasonic cleaning, the purpose is to remove the nickel oxide on the surface of the foam nickel.

[0046] B takes by weighing raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.29g, cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) 0.58g and ammonium nitrate (NH 4 NO 3 ) was dissolved in water and stirred to obtain a mixed solution in which Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O molar ratio is 1:2, ammonium nitrate is 0.08g.

[0047] C. Put the above-mentioned cleaned foamed nickel into the mixed solution of step B, heat to 70° C., and then use the electrochemical deposition method to deposit under the condition of -1V constant voltage for 8 minut...

Embodiment 3

[0055] A kind of NiCo 2 o 4 co x Ni 1-x (OH) 2 / / The preparation of CMK-3 water-based asymmetric supercapacitor, the characteristic steps are: 1) NiCo 2 o 4 co x Ni 1-x (OH) 2 Preparation of:

[0056] A Put the foam nickel of appropriate size into a solution containing 1M hydrochloric acid for ultrasonic cleaning, the purpose is to remove the nickel oxide on the surface of the foam nickel.

[0057] B takes by weighing raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) 0.29g, cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) 0.58g and ammonium nitrate (NH 4 NO 3 ) was dissolved in water and stirred to obtain a mixed solution in which Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 O molar ratio is 1:2, ammonium nitrate is 0.08g.

[0058] C. Place the cleaned nickel foam in the mixed solution of step B, heat to 70° C., and then use the electrochemical deposition method to deposit under the condition of -1V constant voltage for 10 minutes.

[0059] D T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com