Preparation method of high-performance flexible silk fabric electrode material and product thereof

A fabric electrode and high-performance technology, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low flexibility and capacitance, cost and complex preparation process, so as to improve the area specific capacitance and realize large-scale The production and preparation process is simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

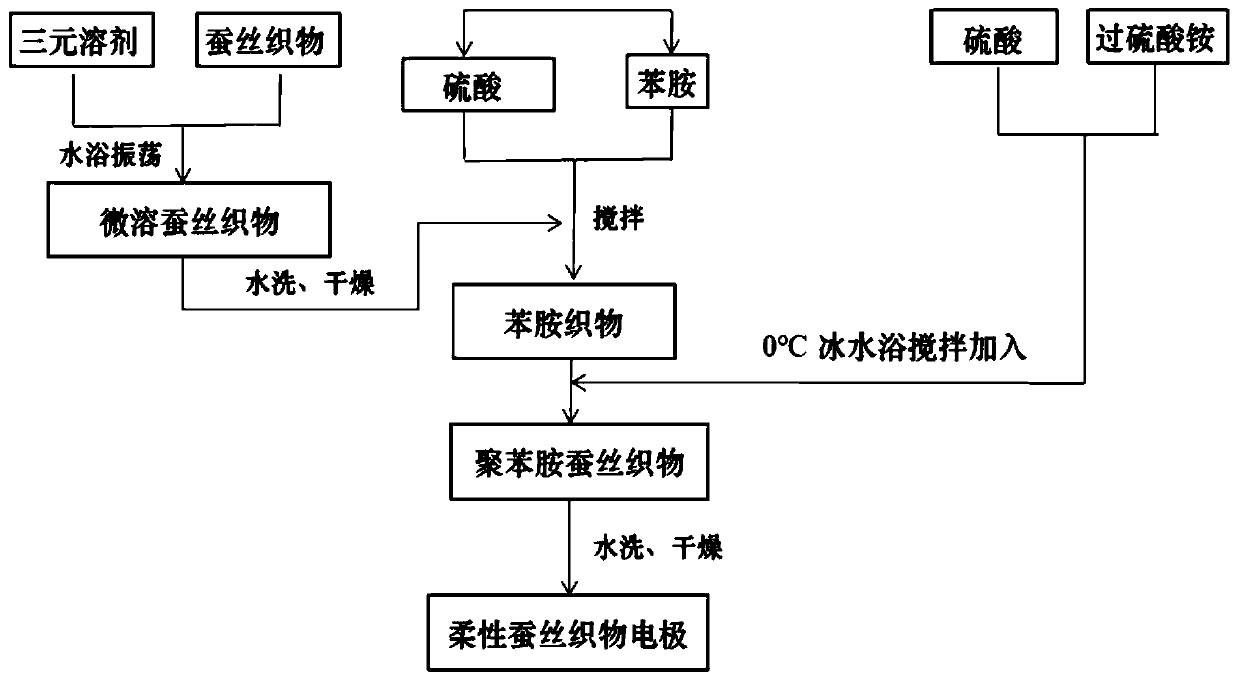

Method used

Image

Examples

Embodiment 1

[0029] (1) The silk fabric of 5cm×5cm was first ultrasonically washed in deionized water for 10min, and then added to the ternary solution according to the mass volume ratio of 1:60 (wherein the ternary solution was composed of CaCl 2 、H 2 O and C 2 h 5 OH according to the molar ratio of 1:8:2), shake at a rate of 100r / min for 30min in a water bath at 40°C to slightly dissolve the silk fabric, and then wash and dry;

[0030] (2) Put the above-mentioned dried fabric into a mixed solution composed of 1mol / L sulfuric acid and 0.64mol / L aniline monomer and stir for 60min (wherein the bath ratio of the fabric to the mixed solution is 1:150);

[0031] (3) under the condition of ice-water bath again, under the stirring speed of 600r / min, to above-mentioned solution, add the mixed solution that the sulfuric acid of 1mol / L and ammonium persulfate form (wherein ammonium sulfate and step (2) in the mixed solution The number of moles of aniline monomers is equal, the bath ratio of the ...

Embodiment 2

[0035] (1) The silk fabric of 5cm×5cm was first ultrasonically washed in deionized water for 5min, and then added to the ternary solution according to the mass volume ratio of 1:70 (wherein the ternary solution was composed of CaCl 2 、H 2 O and C 2 h 5 OH according to the molar ratio of 1:8:2), shake at a rate of 120r / min for 20min in a water bath at 50°C to dissolve the silk fabric slightly, and then wash and dry;

[0036] (2) Put the above-mentioned dried fabric into a mixed solution composed of 2mol / L sulfuric acid and 1.0mol / L aniline monomer and stir for 40min (wherein the bath ratio of the fabric to the mixed solution is 1:140);

[0037] (3) under the condition of ice-water bath again, under the stirring speed of 400r / min, to above-mentioned solution, add the mixed solution that the sulfuric acid of 1mol / L and ammonium persulfate form (wherein ammonium sulfate and step (2) in the mixed solution The number of moles of aniline monomers is equal, the bath ratio of the fa...

Embodiment 3

[0041] (1) The silk fabric of 5cm×5cm was first ultrasonically washed in deionized water for 20min, and then added to the ternary solution according to the mass volume ratio of 1:60 (wherein the ternary solution was composed of CaCl 2 、H 2 O and C 2 h 5 OH according to the molar ratio of 1:8:2), shake at a rate of 80r / min for 30min in a water bath at 30°C to slightly dissolve the silk fabric, and then wash and dry;

[0042] (2) Put the above-mentioned dried fabric into a mixed solution composed of 1mol / L sulfuric acid and 1.16mol / L aniline monomer and stir for 30min (wherein the bath ratio of the fabric to the mixed solution is 1:130);

[0043] (3) under the condition of ice-water bath again, under the stirring speed of 650r / min, to above-mentioned solution, add the mixed solution that the sulfuric acid of 1mol / L and ammonium persulfate form (wherein ammonium sulfate in mixed solution and step (2) The number of moles of aniline monomers is equal, the bath ratio of the fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com