Electrode with flexible self-supporting structure, preparation method and application thereof

A self-supporting structure and electrode technology, applied in the field of electrochemical energy storage, can solve the problems of complex process, low performance, high cost, etc., and achieve the effects of high area specific capacitance, high conductivity, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

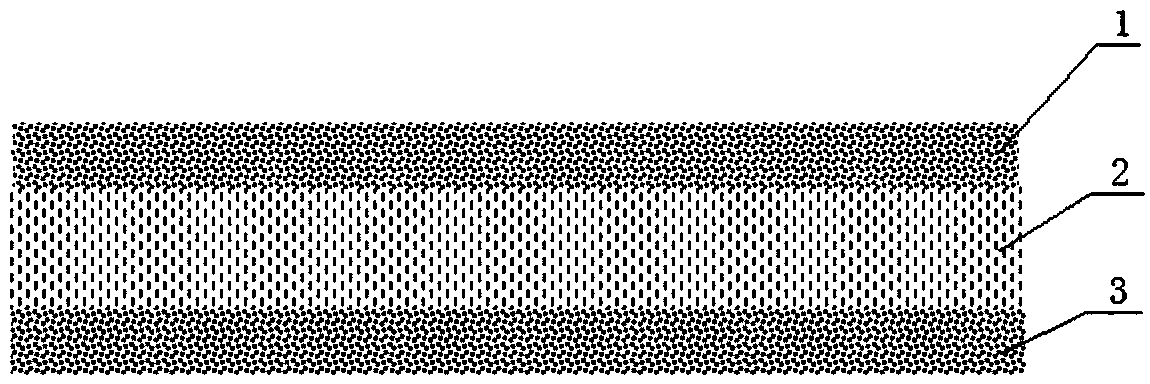

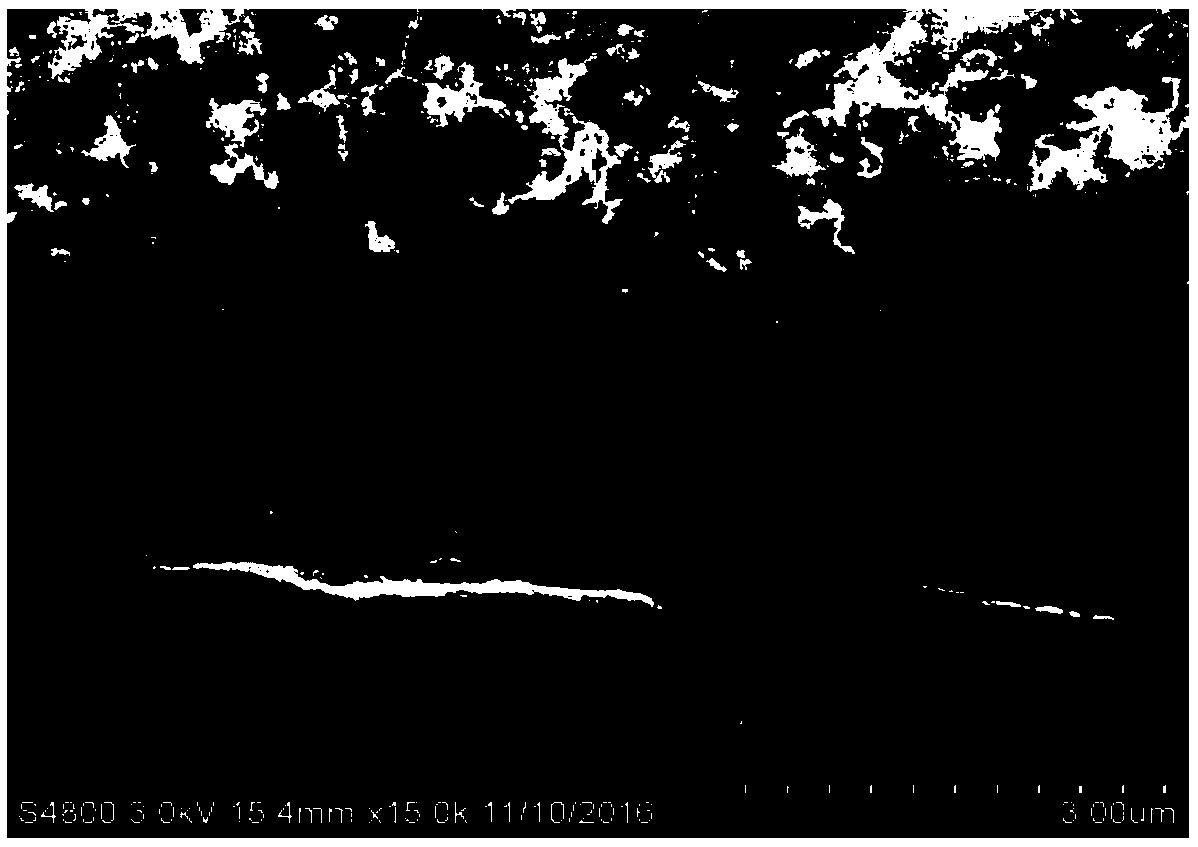

Image

Examples

Embodiment 1

[0041] A method for preparing an electrode with a flexible self-supporting structure, specifically comprising the following steps:

[0042] 1) Using a high-purity titanium sheet as the substrate, sand the titanium sheet substrate with sandpaper to remove oil stains and impurities on the surface, then ultrasonically clean it with acetone, ethanol, and deionized water for 15 minutes, and then dry it;

[0043] 2) Take two titanium substrates with a thickness of 0.20mm and an area of 15mm×20mm, treat them with ozone for 30 minutes, and then place them flat on a 3.00ml container with a concentration of 0.20mg·ml -1 Place the beaker in a 65°C water bath to evaporate the solution to form a GO film;

[0044] 3) Add 2.00ml to the beaker with a concentration of 8.00mg·ml -1VC aqueous solution, continue to evaporate the solution in a 65°C water bath, so as to prepare a layer of RGO film on the titanium substrate;

[0045] 4) Prepare the first precursor aqueous solution, which contain...

Embodiment 2

[0052] A method for preparing an electrode with a flexible self-supporting structure, specifically comprising the following steps:

[0053] 1) Using a high-purity titanium sheet as the substrate, sand the titanium sheet substrate with sandpaper to remove oil stains and impurities on the surface, then ultrasonically clean it with acetone, ethanol, and deionized water for 15 minutes, and then dry it;

[0054] 2) Take two titanium substrates with a thickness of 0.20mm and an area of 15mm×20mm, and treat the surface with ozone chemical modification for 25 minutes, and then place them flat on a 3.00ml container with a concentration of 0.20mg·ml -1 Place the beaker in a 60°C water bath to evaporate the solution to form a GO film;

[0055] 3) Add 2.00ml to the beaker with a concentration of 8.00mg·ml -1 VC aqueous solution, continue to evaporate the solution in a 60°C water bath, so as to prepare a layer of RGO film on the titanium substrate;

[0056] 4) Prepare the first precurs...

Embodiment 3

[0063] A method for preparing an electrode with a flexible self-supporting structure, specifically comprising the following steps:

[0064] 1) Using a high-purity titanium sheet as the substrate, sand the titanium sheet substrate with sandpaper to remove oil stains and impurities on the surface, then ultrasonically clean it with acetone, ethanol, and deionized water for 15 minutes, and then dry it;

[0065] 2) Take two titanium sheet substrates with a thickness of 0.20mm and an area of 15mm×20mm, treat them with ozone for 40 minutes, and then place them flat on a 3.00ml container with a concentration of 0.20mg·ml -1 The bottom of the beaker of the GO aqueous solution, the beaker is placed in an 80 ° C water bath, the solution is evaporated, and a layer of GO film is formed;

[0066] 3) Add 2.00ml to the beaker with a concentration of 8.00mg·ml -1 VC aqueous solution, and continue to evaporate the solution in a water bath at 80 ° C, so as to prepare a layer of RGO film on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com