A supercapacitor based on antifreeze hydrogel electrolyte and its preparation method

A gel electrolyte, supercapacitor technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as limiting the application of flexible solid-state supercapacitors, unfavorable green supercapacitor construction, and easy freezing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

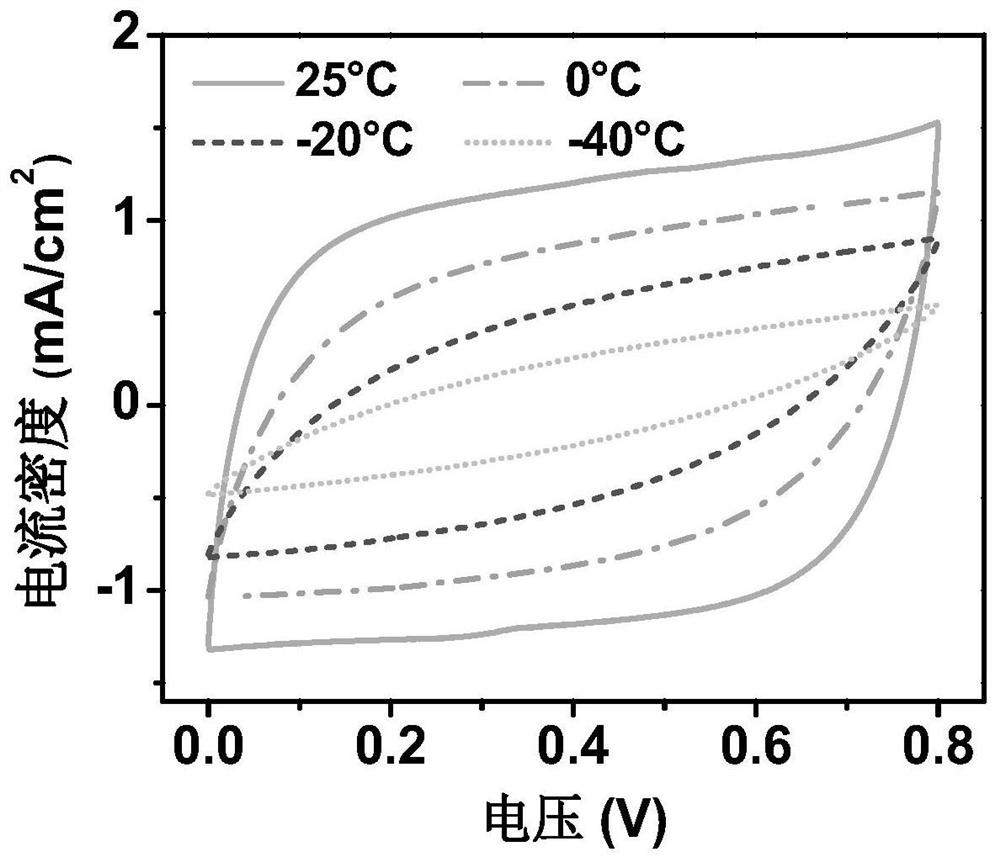

[0049] This embodiment provides a supercapacitor based on an antifreeze hydrogel electrolyte and a preparation method thereof.

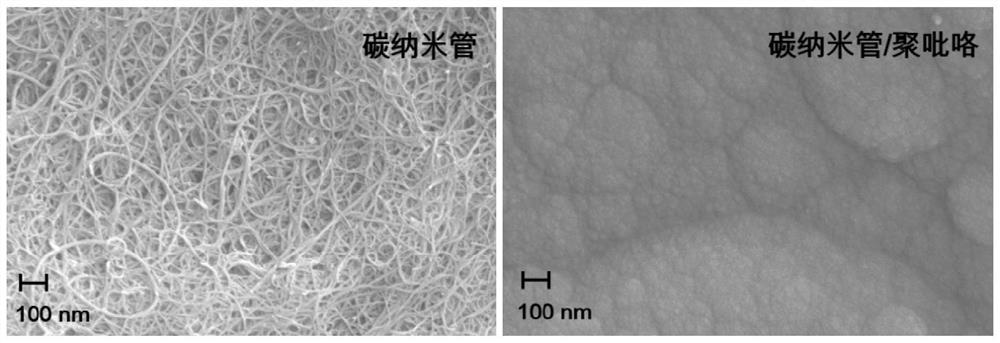

[0050] The preparation method comprises the following steps: cutting the antifreeze hydrogel and the carbon nanotube paper / polypyrrole electrode material into regular rectangles respectively, and then attaching two pieces of carbon nanotube paper / polypyrrole electrode material to the antifreeze hydrogel electrolyte on both sides, resulting in a supercapacitor.

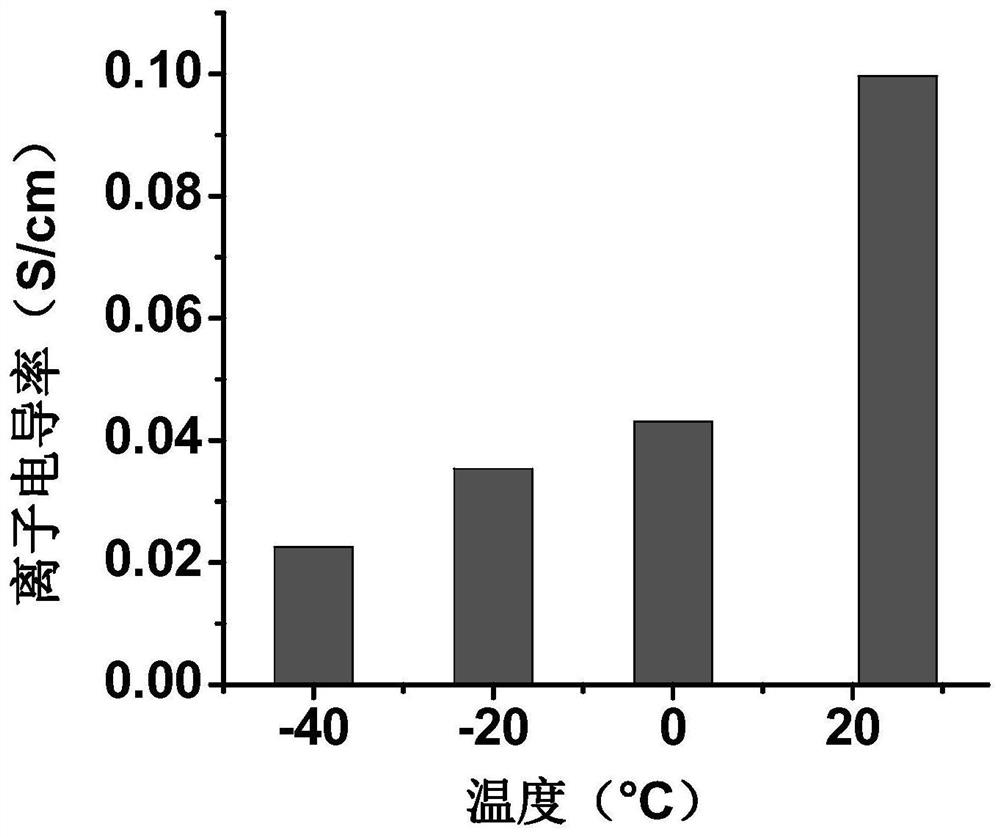

[0051] The antifreeze hydrogel electrolyte was prepared by the following method: Weigh 1.5g lithium chloride and dissolve it in 3mL of 1wt% cellulose nanofiber suspension; weigh 1.5g acrylamide and add it to the above cellulose nanofiber / chlorinated Lithium suspension; then add ammonium persulfate, N,N-methylenebisacrylamide and N,N,N',N'-tetramethylethylenediamine, so that the concentration of ammonium persulfate in the suspension is 1.4 wt%, the concentration of N,N-methylenebisacrylamide ...

Embodiment 2

[0055] This embodiment provides a supercapacitor based on an antifreeze hydrogel electrolyte and a preparation method thereof.

[0056] The preparation method comprises the following steps: cutting the antifreeze hydrogel and the carbon nanotube paper / polypyrrole electrode material into regular rectangles respectively, and then attaching two pieces of carbon nanotube paper / polypyrrole electrode material to the antifreeze hydrogel electrolyte on both sides, resulting in a supercapacitor.

[0057] The antifreeze hydrogel electrolyte was prepared by the following method: Weigh 0.9g lithium chloride and dissolve it in 3mL of 1wt% cellulose nanofiber suspension; weigh 1.5g acrylamide and add it to the above cellulose nanofiber / chlorinated Lithium suspension; then add ammonium persulfate, N,N-methylenebisacrylamide and N,N,N',N'-tetramethylethylenediamine, so that the concentration of ammonium persulfate in the suspension is 1.4 wt%, the concentration of N,N-methylenebisacrylamide ...

Embodiment 3

[0061] This embodiment provides a supercapacitor based on an antifreeze hydrogel electrolyte and a preparation method thereof.

[0062] The preparation method comprises the following steps: cutting the antifreeze hydrogel and the carbon nanotube paper / polypyrrole electrode material into regular rectangles respectively, and then attaching two pieces of carbon nanotube paper / polypyrrole electrode material to the antifreeze hydrogel electrolyte on both sides, resulting in a supercapacitor.

[0063] The antifreeze hydrogel electrolyte was prepared by the following method: Weigh 0.3g lithium chloride and dissolve it in 3mL of 1wt% cellulose nanofiber suspension; weigh 1.5g acrylamide and add it to the above cellulose nanofiber / chlorinated Lithium suspension; then add ammonium persulfate, N,N-methylenebisacrylamide and N,N,N',N'-tetramethylethylenediamine, so that the concentration of ammonium persulfate in the suspension is 1.4 wt%, the concentration of N,N-methylenebisacrylamide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com