Hydroxy-terminated hyperbranched polyamine-ester polymer and application thereof in microfluidic chip

A hydroxyl-terminated hyperbranched, microfluidic chip technology, applied in the field of polymers, can solve problems such as detection and separation of unfavorable separation substances, reduced detection efficiency of detectors, and increased sample diffusion, and achieves improved hydrophilicity, inhibition of adsorption, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

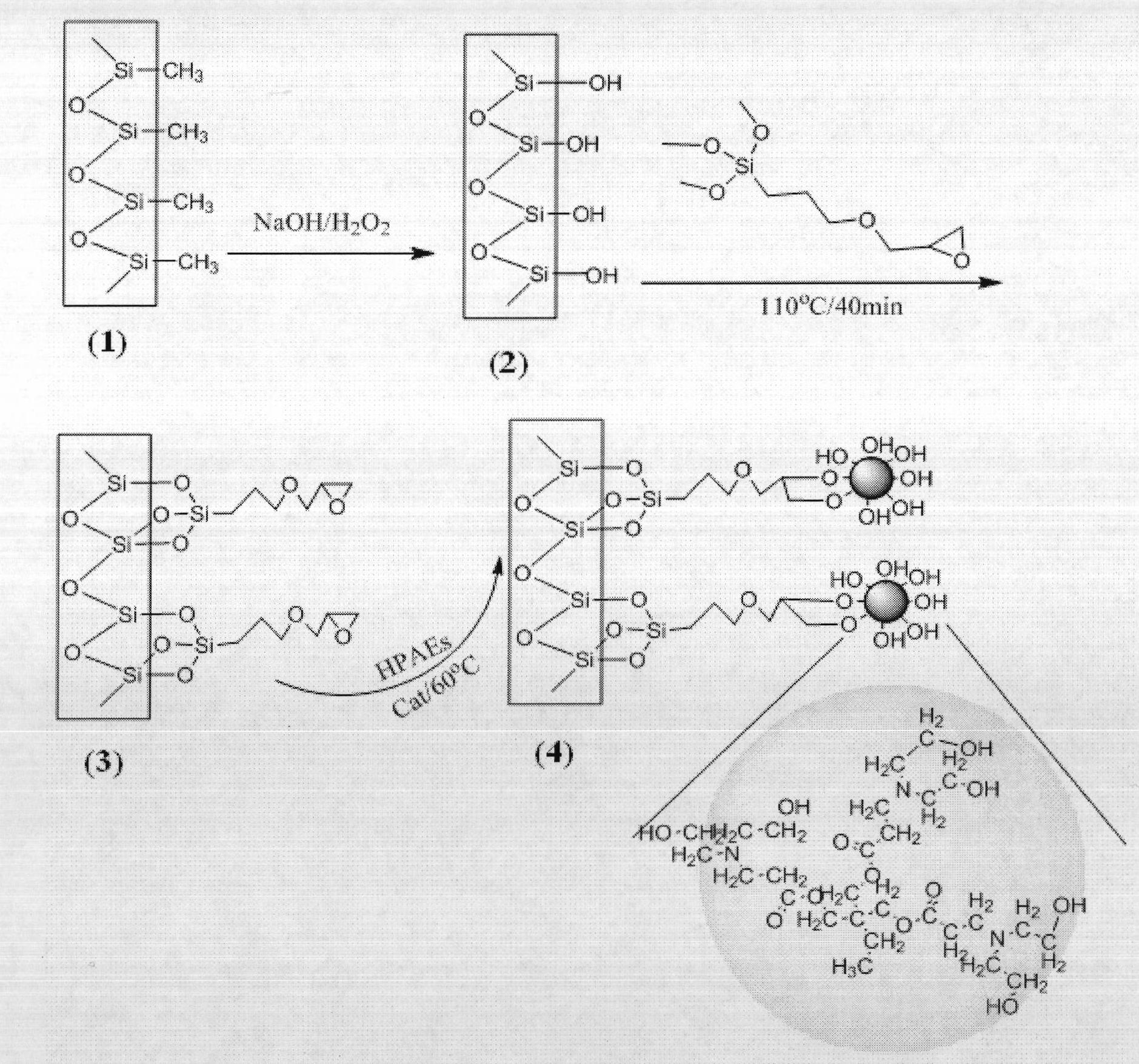

[0041] Example 1 Preparation of G2 generation hydroxyl-terminated hyperbranched polyamine-ester polymer

[0042] Pass nitrogen gas into a 250mL three-necked flask for 10 minutes, take 0.2mol diethanolamine, 0.2mol methyl acrylate and 10ml methanol, mix them evenly in a small beaker and add them to the three-necked flask, and ventilate the mixture with nitrogen gas at room temperature for 10 minutes, stir for 30 minutes and heat up to 35°C After keeping for 4 hours, the methanol was distilled off under reduced pressure to obtain a colorless and transparent oily substance N, N-dihydroxyethyl-3-aminopropionic acid methyl ester, the reaction formula is shown below.

[0043]

[0044] Add 0.045mol of synthesized monomers, 0.045g of p-toluenesulfonic acid and 0.005mol of trimethylolpropane into a 250mL four-neck flask, pass nitrogen gas for 10min, stir until dissolved, then raise the temperature to 85°C and keep it constant, stir for 24h, and then The methanol and unreacted small ...

Embodiment 2

[0046] Example 2 Preparation of G3 generation hydroxyl-terminated hyperbranched polyamine-ester polymer

[0047] Add 0.1mol of N,N-dihydroxyethyl-3-aminopropionic acid methyl ester synthesized in Example 1, 0.0986g of p-toluenesulfonic acid and 0.004761mol of trimethylolpropane into a 250mL four-necked flask, and pass nitrogen gas for 10min , stirred to be dissolved, then heated to 85°C and kept constant, stirred for 24 hours, and then distilled off the methanol and unreacted small molecular compounds in the reaction to obtain the G3 generation of hydroxyl-terminated hyperbranched polyamine-ester polymer. Wherein, the molar ratio of trimethylolpropane and N, N-dihydroxyethyl-3-aminopropionic acid methyl ester is 1: 21, and the structural formula of the G3 generation terminal hydroxyl hyperbranched polyamine-ester polymer is as mentioned above Show.

Embodiment 3

[0048] Example 3 Preparation of G4 generation hydroxyl-terminated hyperbranched polyamine-ester polymer

[0049] Add 0.2mol of N,N-dihydroxyethyl-3-aminopropionic acid methyl ester synthesized in Example 1, 0.194g of p-toluenesulfonic acid and 0.004448mol of trimethylolpropane into a 250mL four-necked flask, and pass nitrogen gas for 10min , stirred to be dissolved, then heated to 85°C and kept constant, stirred for 24 hours, and then distilled to remove methanol and unreacted small molecular compounds in the reaction to obtain the G4 generation of hydroxyl-terminated hyperbranched polyamine-ester polymer. Wherein, the molar ratio of trimethylolpropane and N, N-dihydroxyethyl-3-aminopropionic acid methyl ester is 1: 45, and the structural formula of the G4 terminal hydroxyl hyperbranched polyamine-ester polymer is as mentioned above Show.

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com