Device for filling at least one container with a filling product

A filling and filling technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of interfering with the accurate determination and adjustment of the filling level, and the filling level signal can no longer be detected. Accuracy issues, drive and control simplification, small size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

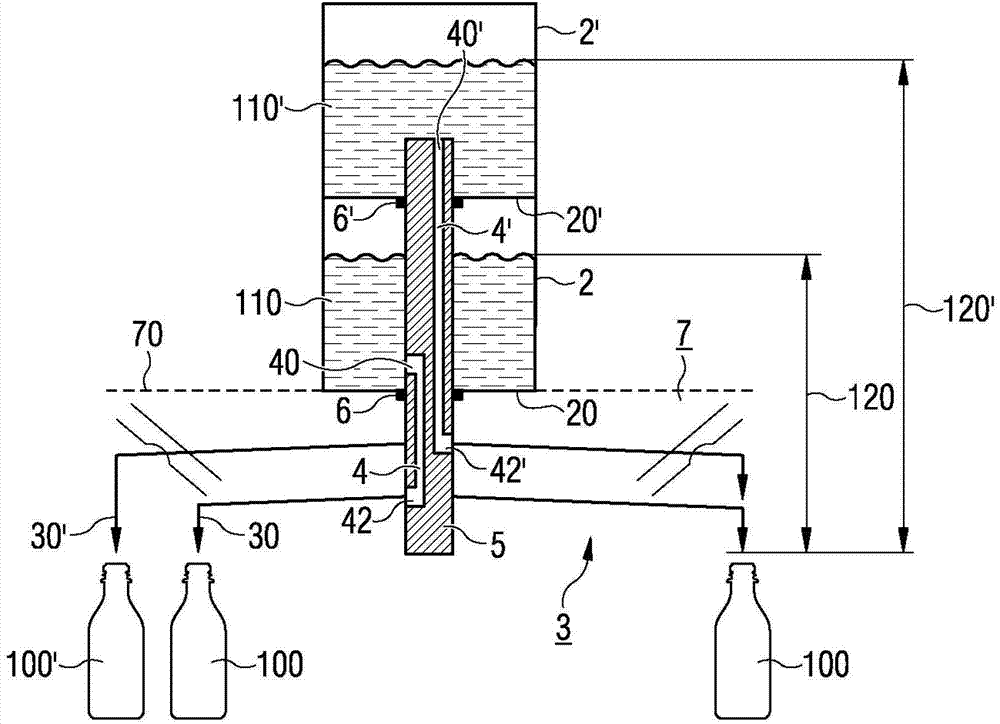

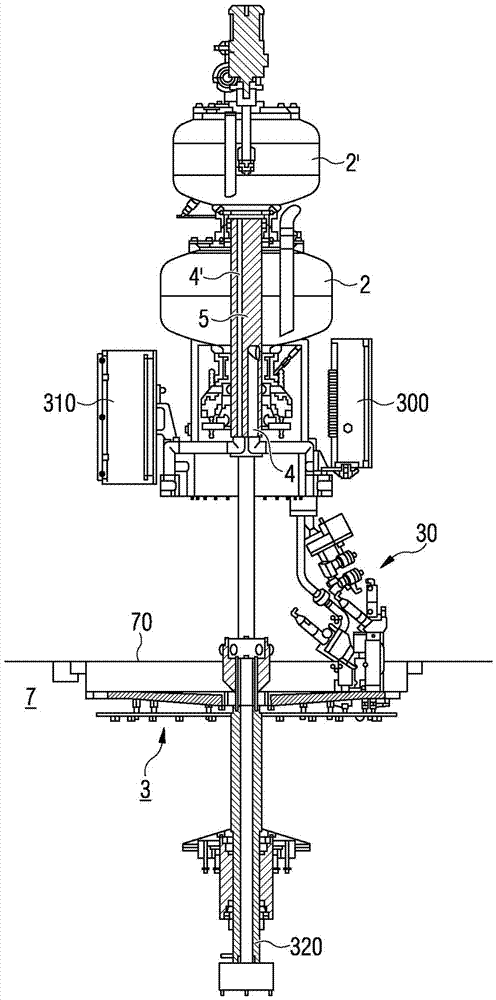

[0044] Preferred embodiments are described below in conjunction with the accompanying drawings. Here, the same, similar or equivalent elements are identified by the same reference numerals in different drawings, and repeated description of these elements is sometimes omitted in the following description to avoid redundancy.

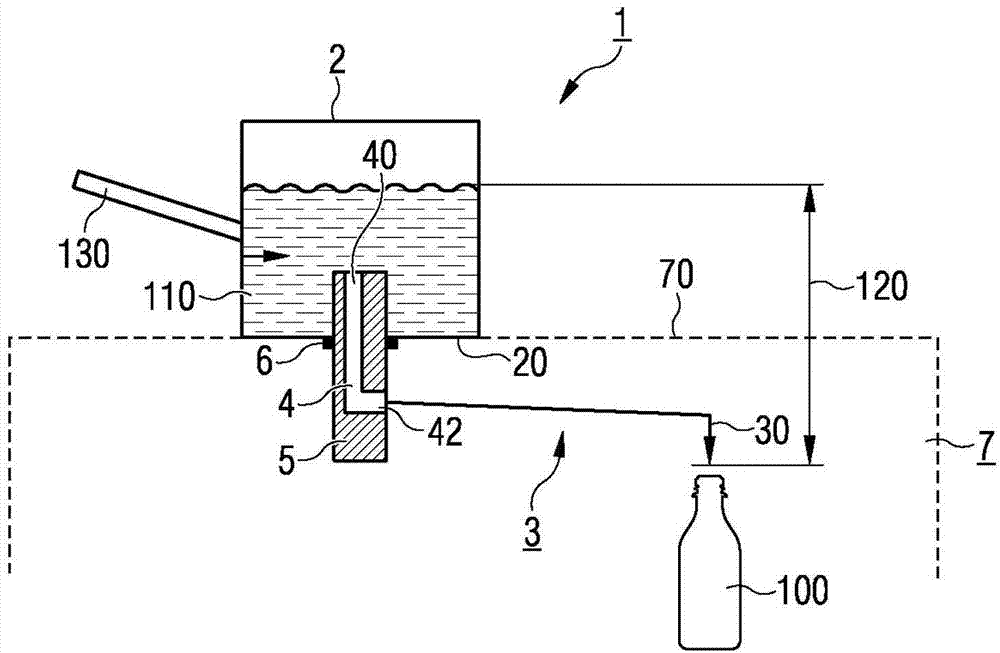

[0045] figure 1 A device 1 is shown for filling at least one container 100 with a filling product 110 .

[0046] A material tank 2 is provided, and the material tank 2 is used to accommodate the filling 110 . A rotor is provided, which is indicated schematically by the reference numeral 3 , wherein the rotor 3 has a schematically indicated filling mechanism 30 for filling the container 100 with a filling product 110 . The rotor 3 is, for example, a filling machine turntable of a rotary filling machine, on which a plurality of filling mechanisms 30 are arranged according to a specific machine division method, so that an efficient and continuous filling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com