Device for purging tapping scrap iron on engine cylinder head production line

A technology for engine cylinder head and engine block, which is applied in the direction of tangent devices, tangent machines, metal processing machinery parts, etc., can solve the problems of affecting the precision of finishing machining, high labor intensity of workers, and low operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

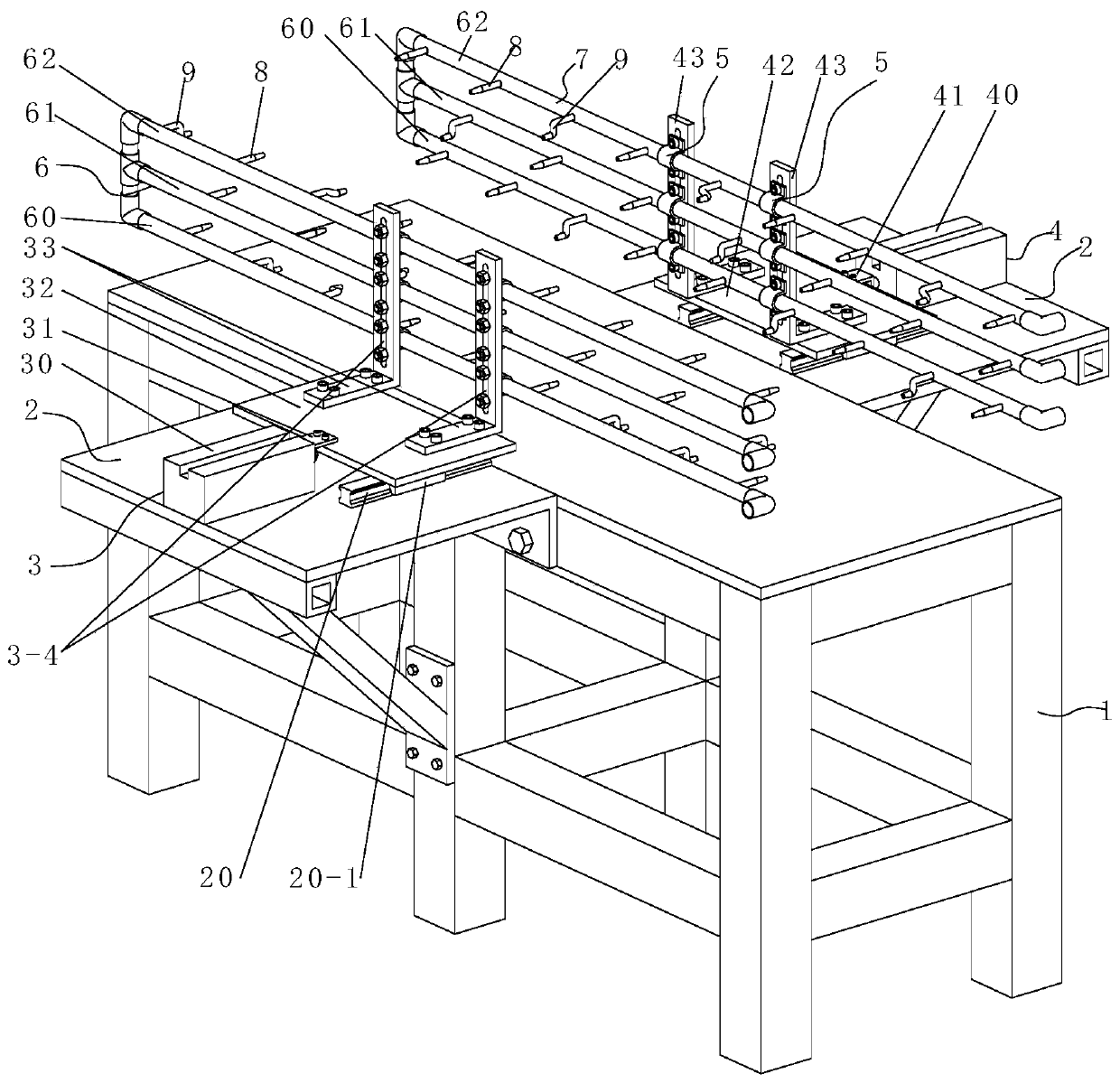

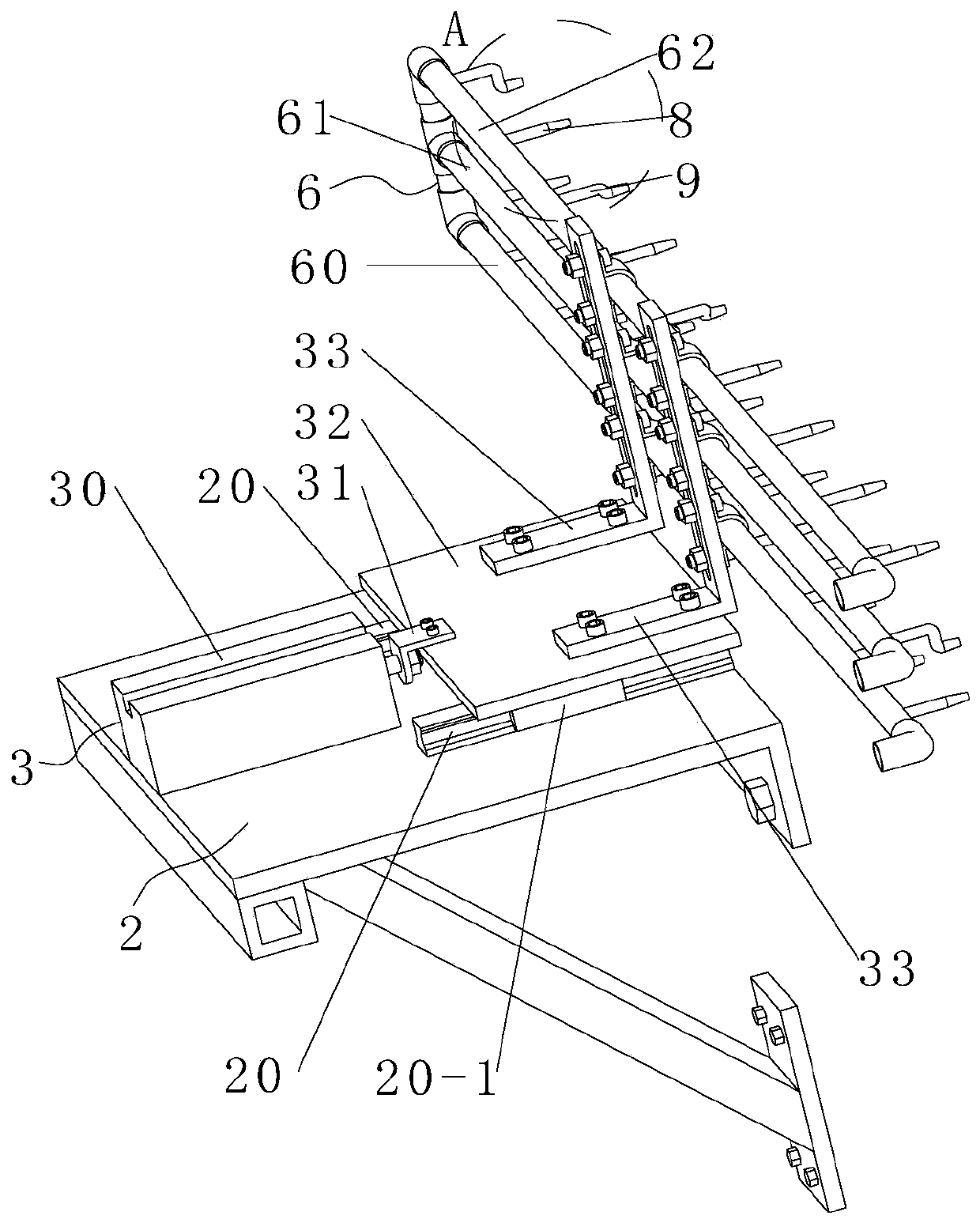

[0033] The tapping iron chip purging device on the engine cylinder head production line, after the cylinder head is transported to the blowing station workbench 1 on the production line, it stops moving, such as Figure 4As shown, when the solenoid valve is opened, the first cylinder 30 in the first drive system 3 and the second cylinder 40 in the second drive system 4 are ventilated respectively, so that the piston rod of the cylinder one 30 pushes the mobile platform through the buckle plate one 31 Plate 1 32 moves forward along the guide rail 20, and at the same time, the piston rod of cylinder 2 40 pushes the mobile platform plate 2 42 to move forward along the guide rail 20 through the fastening plate 2 41, and then the support 1 33 carries the first purge The piping system 6 moves forward, and the bracket 2 43 moves forward with the second purge piping system 7 until each blowing pipe 1 8 and blowing pipe 2 9 are respectively inserted into the deep threaded holes on both ...

Embodiment 2

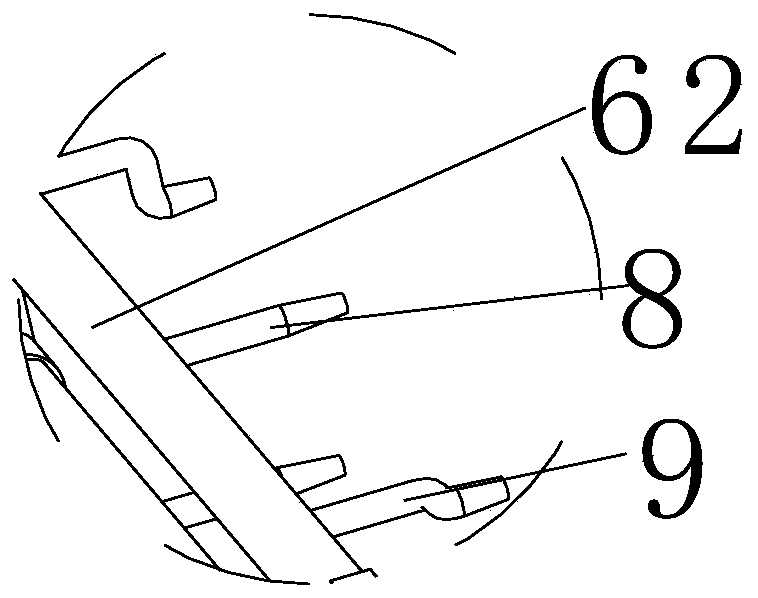

[0035] On the basis of Example 1, the first purge pipeline system 6 is fastened to the bracket one 33 through the half buckle, and the second purge pipeline system 7 is fastened to the bracket two 43 through the half buckle 5 , the first blowing pipe 8 and the second blowing pipe 9 are provided with a plurality, and are communicated with the first purge pipeline system 6 and the second purge pipeline system 7 respectively, and the first blowing pipe 8 and the second blowing pipe 9. The front ends are round table-shaped, and the first bracket 33 and the second bracket 43 are provided with long slots 3-4, which realizes the fine adjustment of the upper and lower positions of the first purge pipeline system 6 and the second purge pipeline system 7, ensuring that the cylinder head The uniformity of the gap left between the inner wall of the deep threaded hole and the outer wall of the front end of the air blowing pipe 8 and the air blowing pipe 2 9 ensures the smoothness of blowing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com