A kind of cap pressing and shaping device

A shaping device and peaked cap technology, which is applied in the direction of shaping/extending circular fabrics, hats, hat products, etc., to achieve the effect of improving the fixing effect, easy control, and simplified operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

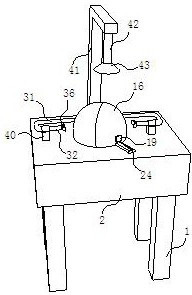

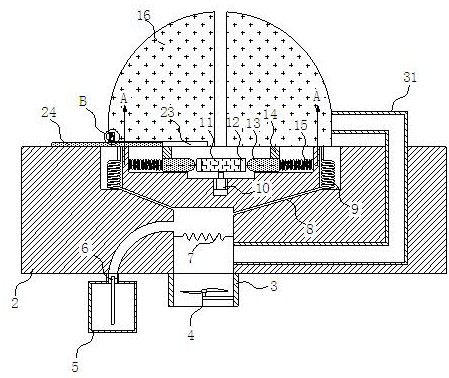

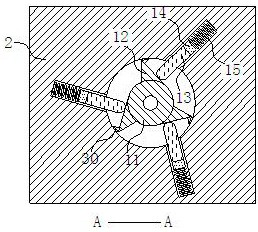

[0046] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a cap pressing and setting device, comprising:

[0047] A workbench 2, the lower surface of the workbench 2 is fixedly connected with a support leg 1 at the corner;

[0048] The air inlet duct 3 is fixedly connected to the center position of the lower surface of the workbench 2, and the interior of the workbench 2 is located directly above the air inlet duct 3 and is provided with a cavity;

[0049] The suction fan 4 is fixedly connected to the inner wall of the air inlet duct 3;

[0050] The water tank 5 is fixedly connected to the position of the lower surface of the workbench 2 close to the air inlet duct 3, and the water tank 5 is connected to the cavity through a pipeline;

[0051] The high-frequency atomizer 6 is fixedly connected to the inside of the upper end of the water tank 5;

[0052] The heating wire 7 is arranged inside the cavity and is fixedly connected with the inner wall of the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com