Manufacturing method of rare earth colored transparent gray crystal bead blank

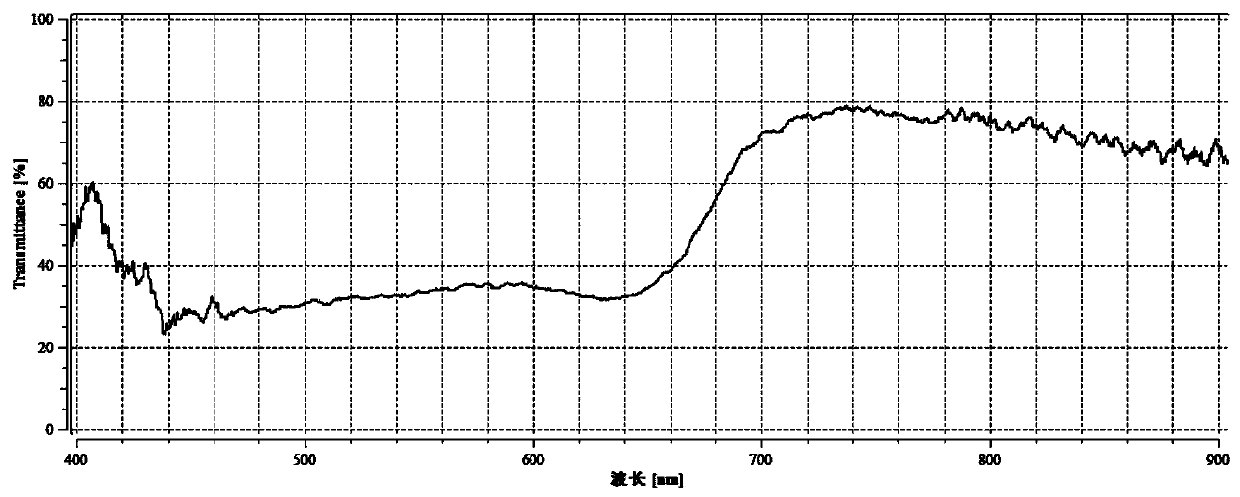

A manufacturing method and technology of crystal bead embryos, which are applied in manufacturing tools, glass pressing, glass manufacturing equipment, etc., can solve problems such as low transmittance and refractive index, color difference of bead embryos, and unstable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

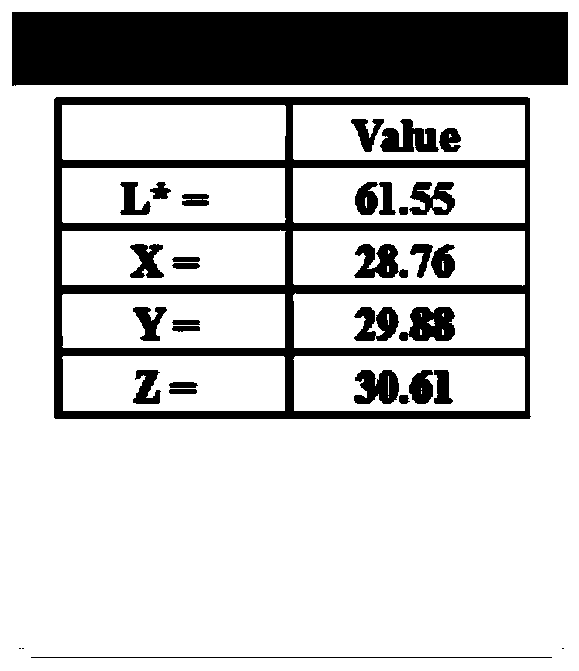

Embodiment 1

[0019] A kind of manufacture method of rare earth coloring transparent gray crystal bead embryo, comprises the following steps:

[0020] S1: Weigh out the raw materials of rare earth colored transparent gray crystal bead embryos according to the weight ratio and mix them evenly; the raw material formula (weight ratio) of the transparent gray crystal bead embryos is: 45 parts of quartz sand with iron content below 5PPM, carbonic acid 10 parts of sodium, 2 parts of potassium carbonate, 3 parts of sodium nitrate, 6 parts of borax decahydrate, 11 parts of zinc oxide, 4 parts of aluminum oxide, 3 parts of calcite, 2 parts of titanium dioxide, 1 part of barium carbonate, 0.5 parts of sodium fluorosilicate , 2 parts of lithium carbonate, 1 part of erbium oxide, 0.1 part of cobalt oxide, 0.3 part of nickel oxide, and 0.5 part of antimony oxide.

[0021] S2: Add the homogeneously mixed mixture into an electric heating closed crucible furnace with a temperature of 1300-1400 degrees Cels...

Embodiment 2

[0027] A kind of manufacture method of rare earth coloring transparent gray crystal bead embryo, comprises the following steps:

[0028] S1: Weigh out the raw materials of rare earth colored transparent gray crystal bead embryos according to the weight ratio and mix them evenly; the raw material formula (weight ratio) of the transparent gray crystal bead embryos is: 50 parts of quartz sand with iron content below 5PPM, carbonic acid 7 parts of sodium, 3 parts of potassium carbonate, 1 part of sodium nitrate, 9 parts of borax decahydrate, 10 parts of zinc oxide, 2 parts of aluminum oxide, 5 parts of calcite, 1 part of titanium dioxide, 1.5 parts of barium carbonate, 1.5 parts of sodium fluorosilicate , 3 parts of lithium carbonate, 1.2 parts of erbium oxide, 0.1 part of cobalt oxide, 0.2 part of nickel oxide, and 0.8 part of antimony oxide.

[0029] S2: Add the homogeneously mixed mixture into an electric heating closed crucible furnace with a temperature of 1300-1400 degrees C...

Embodiment 3

[0034] A kind of manufacture method of rare earth coloring transparent gray crystal bead embryo, comprises the following steps:

[0035] S1: Weigh out the raw materials of rare earth colored transparent gray crystal bead embryos according to the weight ratio and mix them evenly; the raw material formula (weight ratio) of the transparent gray crystal bead embryos is: 42 parts of quartz sand with iron content below 5PPM, carbonic acid 16 parts of sodium, 1.5 parts of potassium carbonate, 2 parts of sodium nitrate, 7 parts of borax decahydrate, 9 parts of zinc oxide, 15 parts of aluminum oxide, 26 parts of calcite, 2 parts of titanium dioxide, 1.8 parts of barium carbonate, 0.9 parts of sodium fluorosilicate , 1 part of lithium carbonate, 1.4 parts of erbium oxide, 0.2 part of cobalt oxide, 0.3 part of nickel oxide, and 0.3 part of antimony oxide.

[0036] S2: Add the homogeneously mixed mixture into an electric heating closed crucible furnace with a temperature of 1300-1400 degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com