Formulation for producing ceramic tile by using phosphorus slag and producing method thereof

A ceramic brick and phosphorus slag technology, which is applied in the field of formula for producing ceramic bricks, can solve the problems of scale pollution, low firing temperature, etc., and achieve the effects of small firing shrinkage, small expansion coefficient, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

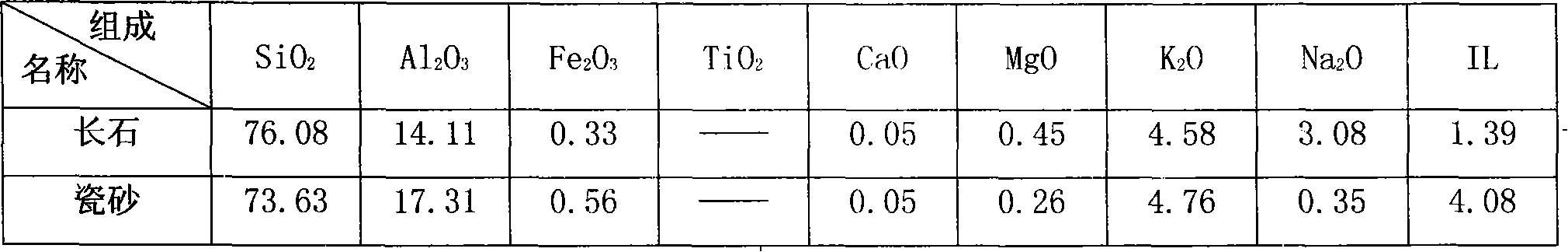

Method used

Image

Examples

Embodiment 1

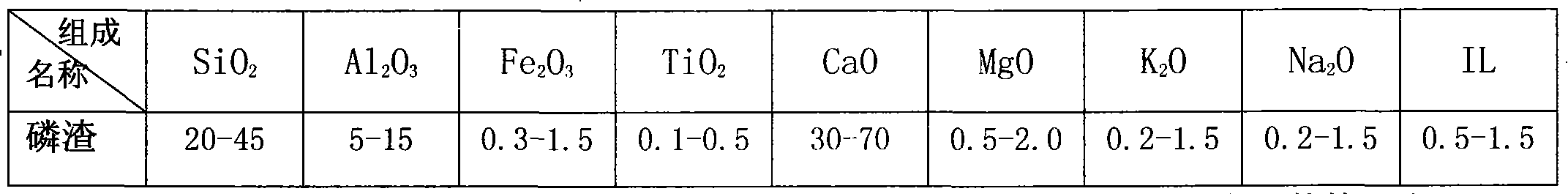

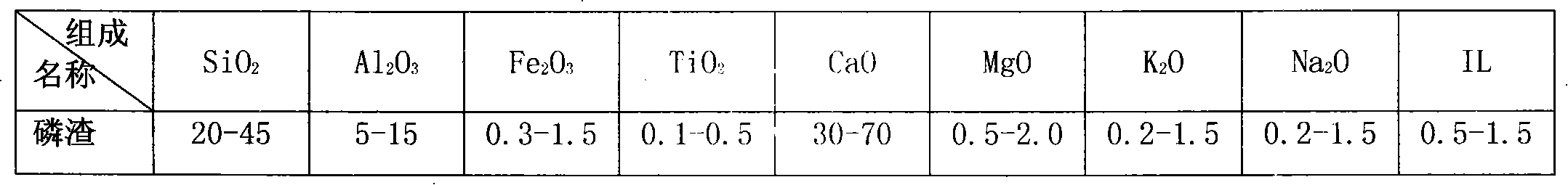

[0029] Take 5 tons of 2# phosphorus slag, 15 tons of feldspar, 20 tons of porcelain sand, 18 tons of Yangbaozhuang clay, 18 tons of Tuguan clay, 13 tons of Luo porcelain clay, 8 tons of Liujie black soil, 3 tons of talc, and add 0.3 tons of water reducer . Each chemical composition of the formula after forming is:

[0030] SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

IL

70.15

14.61

1.32

0.17

3.93

1.27

3.17

0.77

4.59

[0031]According to the above ratio, detect the moisture content of the raw materials, accurately weigh and enter the balls, ball mill until the remainder of the million-hole sieve is ≤ 3%, remove iron and sieve, let the pulp stale, make powder through the spray drying tower, and enter the silo to stale for about 24 hours. Then it is shaped and dried by a press, and then decorated with color dots on the dried body, and t...

Embodiment 2

[0034] Take 35 tons of 2# phosphorus slag, 20 tons of porcelain sand, 15 tons of Bajie clay, 15 tons of Tuguan clay, 10 tons of Liujie black soil, 3 tons of talc, 5 tons of Yangbaozhuang clay, and 0.3 tons of water reducer. Each chemical composition of the formula after forming is:

[0035] SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

IL

59.20

12.03

1.45

0.25

18.89

1.05

2.10

0.3

4.62

[0036] According to the above ratio, detect the moisture content of the raw materials, accurately weigh the balls, ball mill until the remaining ≤ 3% of the million-hole sieve, remove the iron and sieve the pulp and stale, and make powder through the spray drying tower, and the color of the raw materials will be stale for about 24 hours, and then Formed by press and dried. This formula has good whiteness, and various decorations can be carried out on the green body, s...

Embodiment 3

[0039] Take 15 tons of 1# phosphorus slag, 10 tons of feldspar, 18 tons of porcelain sand, 12 tons of Yangbaozhuang clay, 15 tons of Bajie clay, 16 tons of Tuguan clay, 12 tons of Luo porcelain clay, 2 tons of talc, and add 0.3 tons of water reducing agent. Each chemical composition of the formula after forming is:

[0040] SiO 2

Al 2 o 3

Fe 2 o 3

TiO 2

CaO

MgO

K 2 o

Na 2 o

IL

65.96

14.34

1.87

0.24

8.10

1.25

2.25

0.61

4.46

[0041] According to the above ratio, detect the moisture content of the raw materials, accurately weigh the balls, ball mill until the remaining ≤ 4% of the million-hole sieve, remove the iron and sieve the pulp and stale, and make powder through the spray drying tower, and the color of the raw materials will be stale for about 24 hours, and then It is mixed with black pigment, shaped by press, dried, applied with trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com