Halogen-free high-impedance soldering flux and preparation method

A high-impedance, flux technology, applied in the direction of welding equipment, welding media, manufacturing tools, etc., can solve the problem of reducing the surface insulation resistance of circuit boards and component pins, which cannot meet the high reliability requirements of high-end electronic products, and is difficult to meet the requirements of wireless Lead process brazing requirements and other issues to achieve the effect of improving spreading ability, non-conductive performance, promoting flow and spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

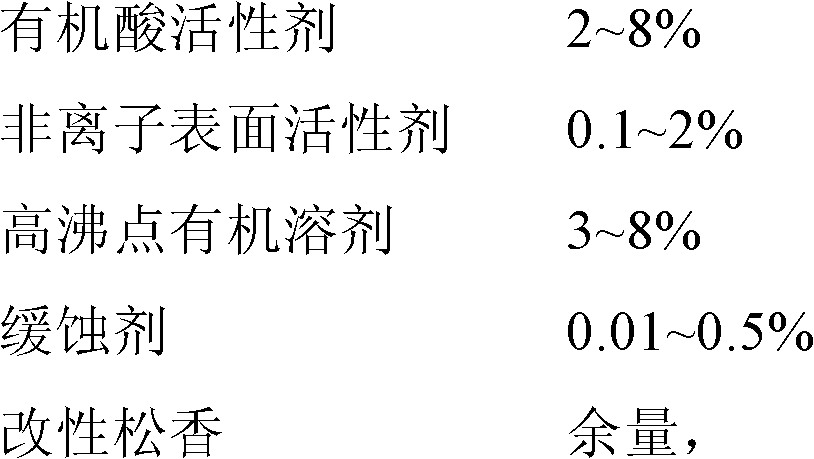

Method used

Image

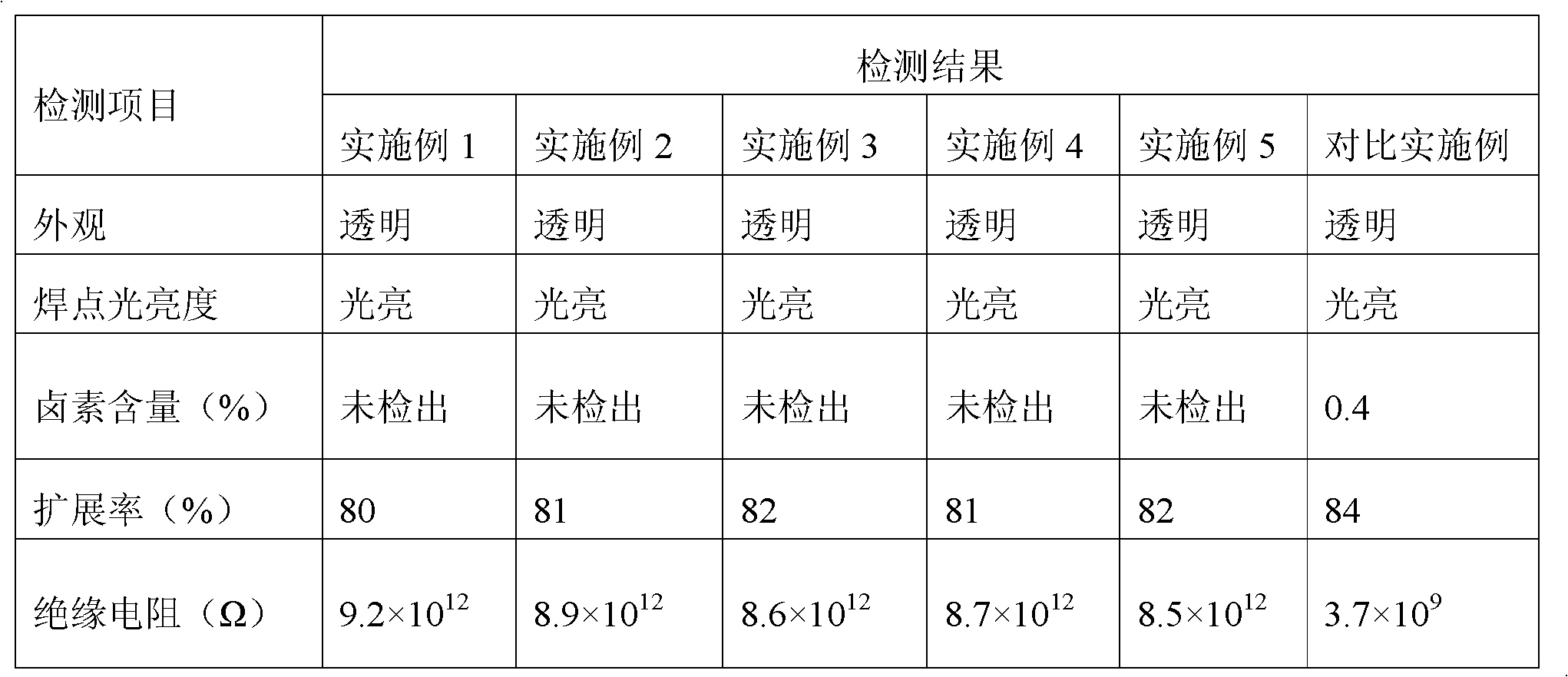

Examples

Embodiment 1

[0024] raw material:

[0025] Polymerized rosin 92.70g, palmitic acid 2g, alkylphenol polyoxyethylene ether 0.5g, nonylphenol polyoxyethylene ether 0.5g,

[0026] Isooctylphenol polyoxyethylene ether 1g, hydroxybenzotriazole 0.1g, methylbenzotriazole 0.1g, triethylamine 0.1g and triethyl carbitol ether 3g.

[0027] Add 92.70g of polymerized rosin into the container, heat and stir until completely melted, then add 2g of hexadecanic acid, 0.5g of alkylphenol polyoxyethylene ether, 0.5g of nonylphenol polyoxyethylene ether, 1g of iso Octylphenol polyoxyethylene ether, 0.1g hydroxybenzotriazole, 0.1g methylbenzotriazole, 0.1g triethylamine and 3g triethyl carbitol ether, continue to stir for 30 minutes to make halogen-free high resistive flux.

Embodiment 2

[0029] raw material:

[0030] 48.5g of polymerized rosin, 40g of hydrogenated rosin, 2g of glutaric acid, 2g of adipic acid, 1g of dodecanoic acid, 0.5g of fatty alcohol polyoxyethylene ether, 0.5g of polyethylene glycol monoester, 0.5g of triethylamine, Triethylene glycol monobutyl ether 2g and triethyl carbitol ether 3g,

[0031] Add 48.5g of polymerized rosin and 40g of hydrogenated rosin into the container, heat and stir until completely melted, then add 2g of glutaric acid, 2g of adipic acid, 1g of dodecanoic acid, and 0.5g of fatty alcohol polyoxyethylene ether in sequence at 140°C , 0.5g polyethylene glycol monoester, 0.5g triethylamine, 2g triethylene glycol monobutyl ether and 3g triethyl carbitol ether, and continue to stir for 25 minutes to prepare a halogen-free high-impedance flux.

Embodiment 3

[0033] raw material:

[0034] Water white rosin 42.4g, polymerized rosin 20g, hydrogenated rosin 25g, suberic acid 3g, sebacic acid 3g, alkylphenol polyoxyethylene ether 0.2g, nonylphenol polyoxyethylene ether 0.3g, benzotriazole 0.05 g, 0.05 g of hydroxybenzotriazole, and 6 g of triethylene glycol ethyl ether.

[0035] Add 42.4g of water-white rosin, 20g of polymerized rosin, and 25g of hydrogenated rosin into the container, heat and stir until completely melted, and then add 3g of suberic acid, 3g of sebacic acid, and 0.2g of alkylphenol polyoxyethylene at a temperature of 150°C. ether, 0.3g nonylphenol polyoxyethylene ether, 0.05g benzotriazole, 0.05g hydroxybenzotriazole, 6g triethylene glycol ethyl ether, and continue to stir for 20 minutes to prepare a halogen-free high-impedance flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com