Green archaized brick prepared from iron tailings of skarn with high content of calcium and magnesium and making method thereof

A high-calcium-magnesium skarn type and magnesium skarn type technology is applied in the field of building ceramic materials, which can solve the problems of restricting the production and development of antique bricks of ceramic materials, rising raw material prices, etc., and save resources and costs of high-quality ceramic raw materials. The effect of low and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

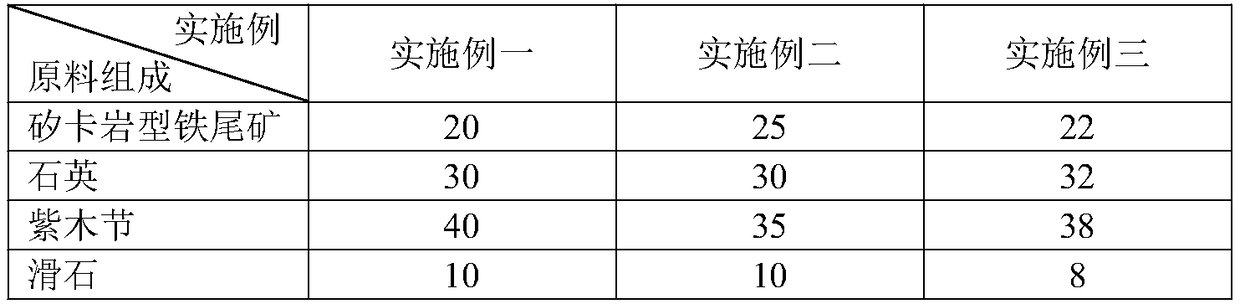

[0020] The embodiment of the present invention is an antique brick body using high-calcium-magnesium skarn-type iron tailings as raw materials. The raw materials are composed of 20-25 parts of skarn-type iron tailings and 30-40 parts of quartz in parts by weight. , 35-45 parts of purple wood knot, 6-12 parts of talc. The raw material composition of each embodiment is as shown in table 1.

[0021] The mineral composition of the skarn-type iron tailings used is: calcite 33.7wt%, diopside 28.2wt%, quartz 13.8wt%, chlorite 10.4wt%, feldspar 4.2wt%, actinolite 1.7wt% %, andandite 1.3wt%, phlogopite 1.1wt%, pyrite 3.4wt%, magnetite 2.2wt%. Its chemical composition is: SiO 2 34.78wt%, TiO 2 0.23wt%, Al 2 o 3 6.46wt%, Fe 2 o 3 8.98wt%, MgO 14.67wt%, CaO 28.79wt%, Na 2 O 0.93wt%, K 2 O0.87wt%, I.L 4.29wt%.

[0022] Table 1 The raw material composition (parts by weight) of the archaized brick adobe body of each embodiment of the present invention

[0023]

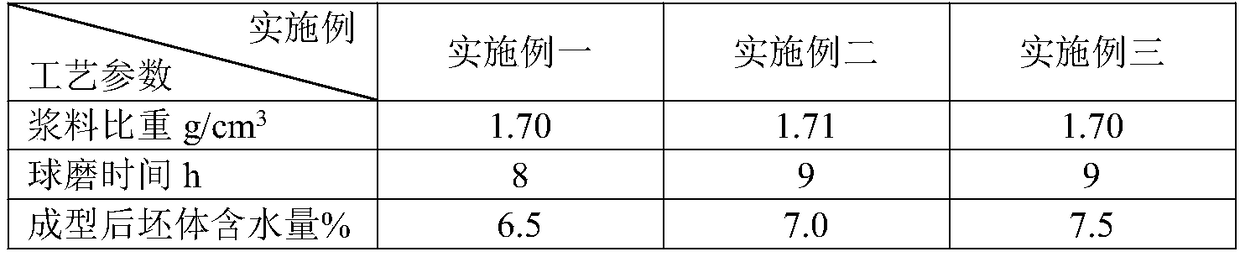

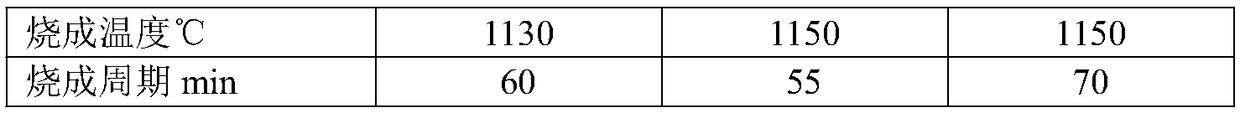

[0024] Each emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com