Thin type temperature fuse and fluxing medium therefore

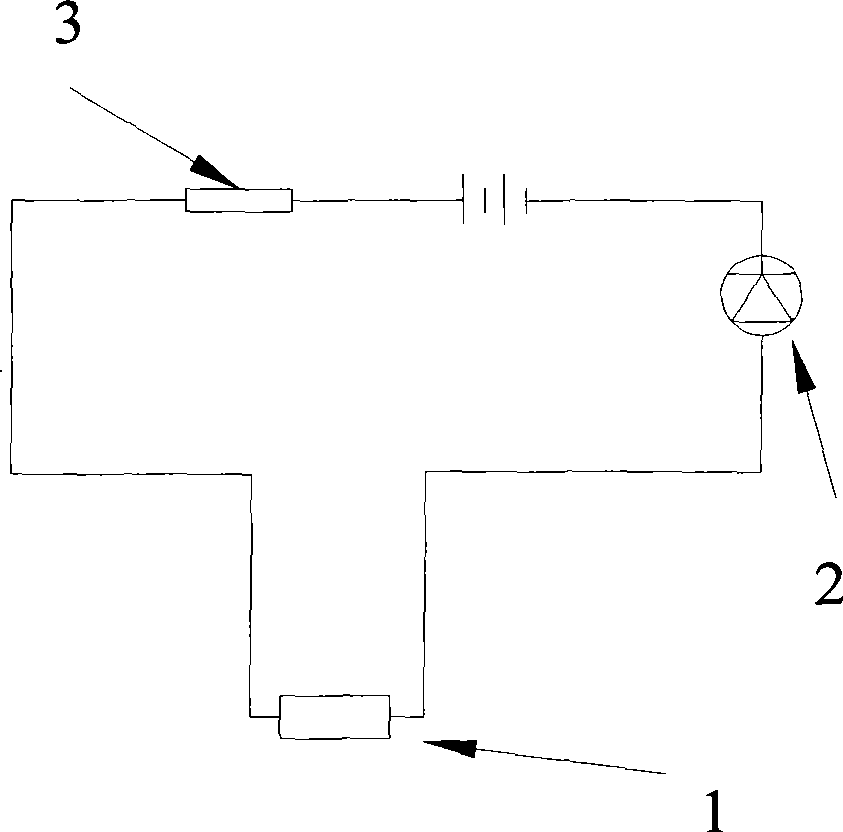

A temperature fuse and flux technology, applied in the direction of electrical components, circuits, emergency protection devices, etc., can solve the problems of high corrosion, easy oxidation, discoloration, acidity, and large crystallization tendency, and achieve good long-term durability and low volatility , the effect of high flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

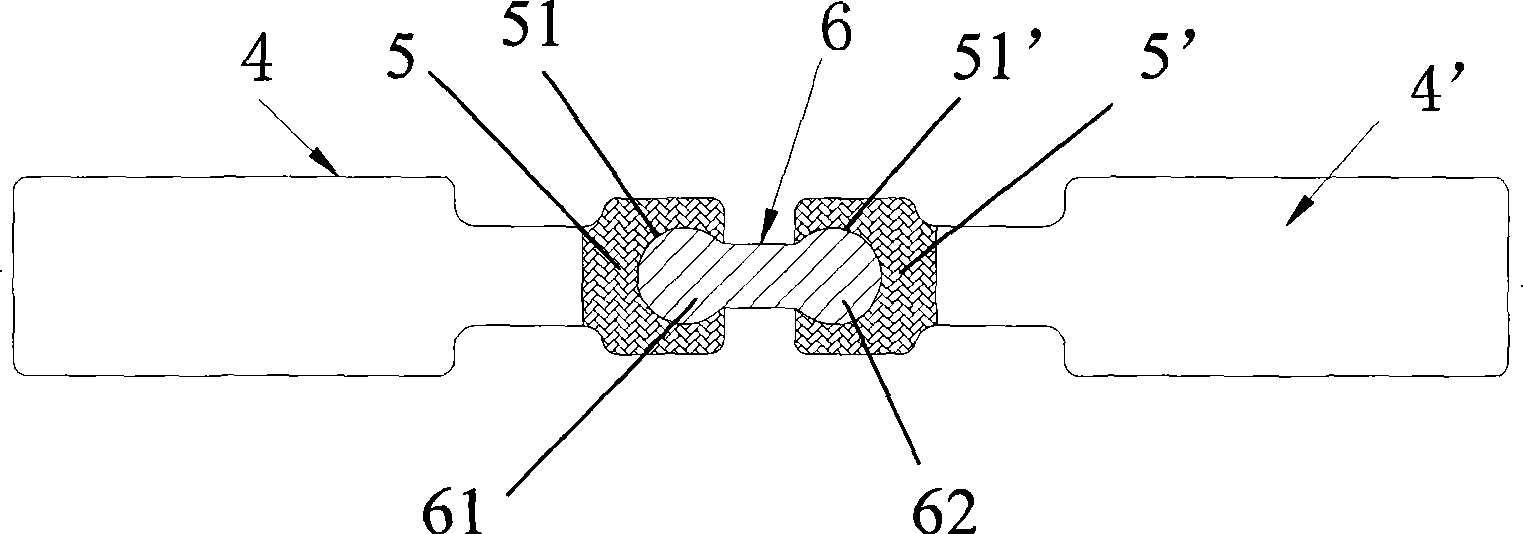

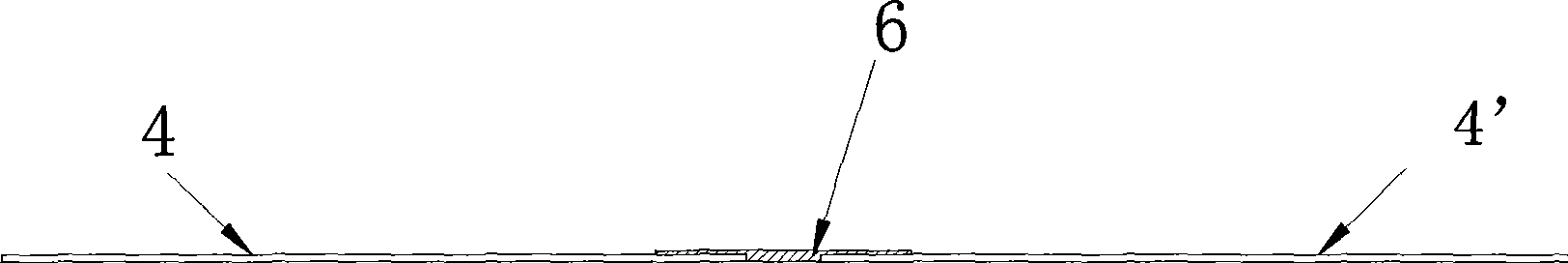

Method used

Image

Examples

Embodiment 1

[0049] A flux for a thin temperature fuse. The preparation method is as follows: Weigh 40g of disproportionated rosin, add 4ml of ethanol to a water bath and heat it to melt, measure 8ml of diglycolamine, add it slowly, stir while adding, and finally dissolve 0.5g Mix ethyl silicone oil into it, stir evenly, and make flux A after cooling.

Embodiment 2

[0051] A kind of flux for thin temperature fuse, the preparation method is: weigh 40g of disproportionated rosin, add 4ml of ethanol in a water bath and heat it to melt, measure 8ml of triethanolamine, add it slowly, stir while adding, and finally add 0.5g of ethyl Mix silicone oil into it, stir evenly, and make flux B after cooling.

Embodiment 3

[0053] A kind of flux for thin temperature fuse, the preparation method is: weigh 40g of disproportionated rosin, add 4ml of n-butanol in a water bath and heat it to melt, measure 8ml of diglycolamine, add it slowly, stir while adding, and finally Mix 0.5g of ethyl silicone oil into it, stir evenly, and make flux C after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com