Chemical corrosion-resistance, high-strength and high-modulus glass fiber composition

A technology of chemical corrosion resistance and glass fiber, which is applied in the field of high-performance composite materials, can solve the problems of lower glass fiber molding temperature, high glass fiber molding temperature, and difficult operation, and achieve lower molding temperature, high chemical corrosion resistance, The effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

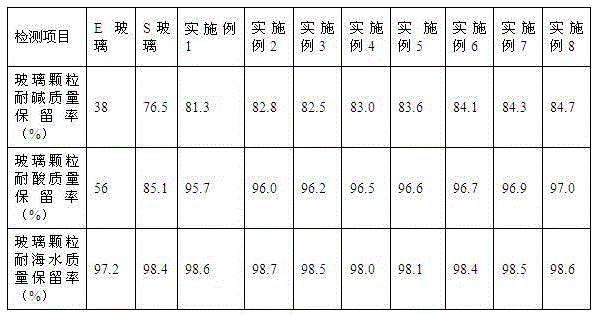

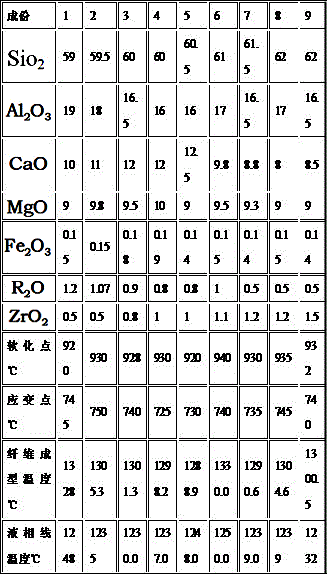

[0041] In the laboratory, the following formula is used to prepare batch materials, melt into glass blocks, and perform performance testing. In order to further verify the present invention, the glass composition of the inventive composition is experimentally produced in the company's tank kiln production device.

[0042] The performance is as follows:

[0043]

[0044] Through the comparison of the above data, it can be found that SiO 2 An increase in the content can effectively increase the strain point and softening point temperature of the glass, that is, improve the temperature resistance of the glass, and broaden the application of the product in the fields of high temperature, acid and alkali resistance, environmental protection engineering, motor vehicle muffler and other fields. The softening point of the glass fiber in the present invention is above 920°C, which is 70-80°C higher than that of ordinary E glass fiber, the strain point is 80°C higher, and the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com