Calcium-based catalyst for regulating and controlling gas components generated in thermal decomposition and preparation method of calcium-based catalyst

A catalyst, calcium-based technology, used in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problem of insufficient combustible gas yield, and achieve the effect of reducing content, promoting reduction reaction, and increasing carbon monoxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

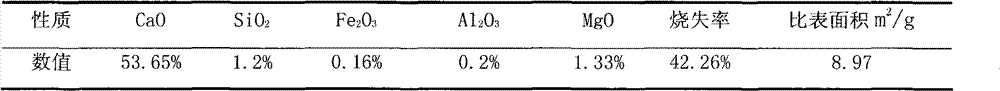

[0020] The ore was collected from limestone tailings 1# in Mentougou, Beijing. The composition content and properties are shown in Table 1. The tailings ore was crushed and screened to a particle size below 0.125mm. A fixed-bed reactor was used for calcination at a temperature of 900° C. without air for 60 minutes. After calcination, quickly take out the material and place it in a desiccator to room temperature, shape it into a powder and seal it for storage as a catalyst. Add the prepared powder into domestic waste for catalytic pyrolysis of waste. The composition of the waste raw materials used is shown in Table 2.

[0021] Table 1 Properties of limestone tailings

[0022]

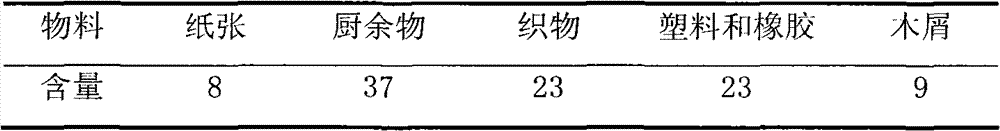

[0023] Composition (%) of table 2 house refuse

[0024]

[0025] The catalyst is directly mixed with the garbage, and the addition amount is 15%. A fixed bed pyrolysis reactor is used for the pyrolysis of domestic waste, the temperature is programmed, the temperature rise rate is 15°C / min, and t...

Embodiment 2

[0032] Limestone tailings 2# collected from Mentougou, Beijing, its composition and properties are shown in Table 5. The raw ore is crushed and screened to below 0.18mm. Calcined at 900°C under air-isolated conditions, and the calcination time was 2h. After calcination, quickly take out the material and place it in a desiccator to dry to room temperature, and use it as a catalyst after granulation. The raw material used is the sludge from Gaobeidian Sewage Treatment Plant, and its properties are shown in Table 6.

[0033] Table 5 Properties of limestone tailings

[0034]

[0035] Table 6 Basic physical and chemical properties of Gaobeidian sludge

[0036]

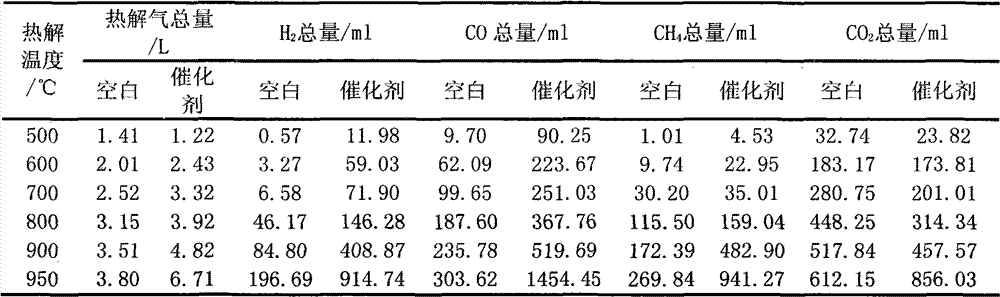

[0037] The catalyst is directly mixed with the sludge, and the addition amount is 10%. The catalytic pyrolysis of sludge was carried out in an external fixed-bed reactor, the temperature was programmed to rise at a rate of 15°C / min, and the final temperature was 950°C. Gas chromatography was used to detect the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com