Method for preparing collophanite reverse flotation collecting agent with drainage oil

A waste oil and reverse flotation technology, applied in flotation, solid separation, etc., can solve problems such as large component fluctuations, high raw material prices, and unstable production, and achieve localized raw materials, low beneficiation costs, and low procurement costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

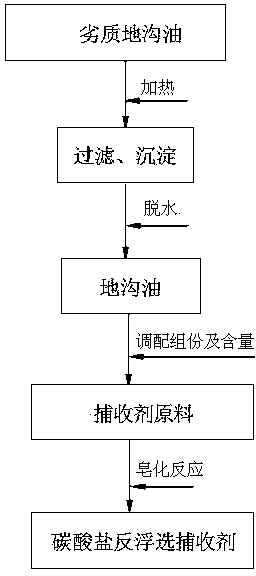

Image

Examples

Embodiment 1

[0019] A method for preparing a collophosite reverse flotation carbonate mineral collector with waste oil, characterized in that it consists of waste oil, alkali and water, and the ratio of waste oil: alkali: water = 1:0.15 in parts by mass Mix at a ratio of ~0.3:400, and react for 1 to 1.5 hours at a constant temperature of 40 to 80°C to prepare a collector for carbonate minerals in reverse flotation of collophanite. The steps are as follows:

[0020] a. Heat the waste oil to 40-80°C, filter and precipitate to remove solid waste, and then dehydrate until the water content of the waste oil is less than 1%;

[0021] b. Detect the components of waste oil, and prepare a mixture with the content of C12~C18 in the waste oil components, and the content of C12~C18 in the waste oil components accounts for about 65% of the total components;

[0022] c. Mix according to the ratio of waste oil: alkali: water = 1:0.15~0.3:400, saponify at a constant temperature of 40~80°C for 1~1.5 hours,...

Embodiment 2

[0025] Detect the components of waste oil, and adjust the content of C12~C18 in the components to account for about 75% of the total components; saponify the raw materials to obtain reverse flotation carbonate mineral collectors. When raw ore P 2 o 5 Content of 22%, MgO content of 5.6% collephosite, add 400 g / ton of raw ore reagent for reverse flotation operation, the content of MgO in the concentrate is 0.85%, and the removal rate of MgO is up to 88%.

Embodiment 3

[0027] The components of waste oil were detected, and the content of C12~C18 in the components was adjusted to about 85% of the total components; the raw materials were subjected to saponification reaction to obtain reverse flotation carbonate mineral collectors. When raw ore P 2 o 5 Content of 22%, MgO content of 5.6% collephosite, add 300 g / ton of raw ore reagent for reverse flotation operation, the content of MgO in the concentrate is 0.80%, and the removal rate of MgO is up to 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com