System and method for calcination/carbonation cycle processing

A cycle treatment and carbonation technology, which is applied in chemical instruments and methods, separation methods, combustible gas purification, etc., can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

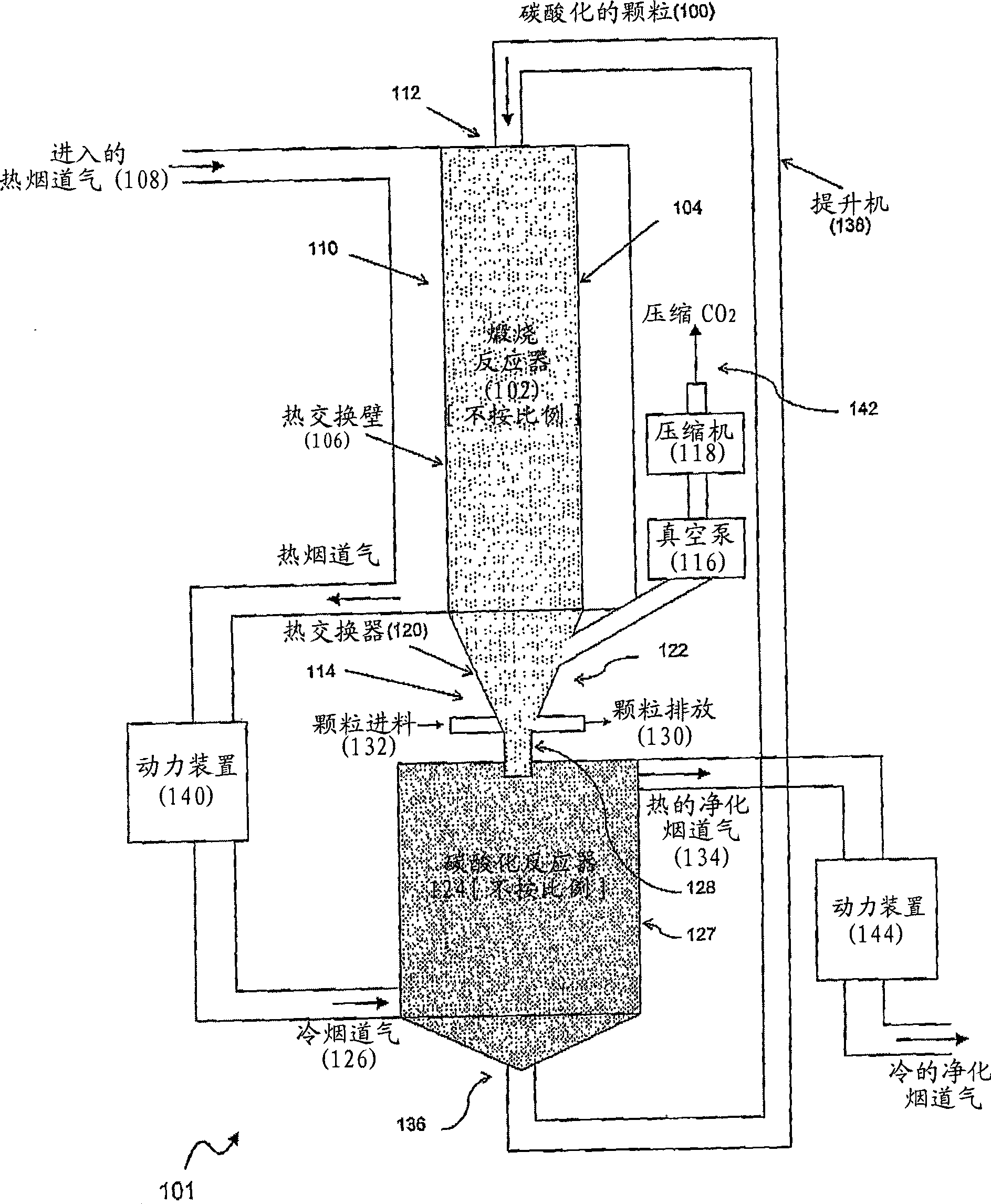

[0047] The described embodiments relate to a regenerative sorbent process using lime particles as feedstock to separate CO from combustion gases 2 and SO x Methods. Embodiments described here use as a general feature a calcination / carbonation cycle that uses reactions based on metal oxide MO(s) sorbents to remove carbon dioxide. The chemical reaction involves the following cycle:

[0048] MO(s)+CO 2 (g)→MCO 3 (s) carbonation (capture of carbon from flue gases)

[0049] MCO 3 (s)→MO(s)+CO 2 (g) Calcination (releases carbon for collection)

[0050] This embodiment is based on a reactor system in which the particles are conveyed pneumatically between a carbonation reactor and a calciner, wherein the flue gas flows through the carbonation reactor, the sorbent is regenerated in the calciner, and the released carbon dioxide is absorbed in the calciner. Purification and, if necessary, mechanical compression of released carbon dioxide for collection.

[0051] This embodiment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com