Swill-cooked dirty oil collophanite reverse flotation collecting agent and preparing method thereof

A technology of reverse flotation and collophosite, applied in flotation, solid separation, etc., to achieve good selectivity, improve the grade of phosphate concentrate, and strong collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of waste oil collophosphane reverse flotation collector preparation method steps are as follows:

[0026] 1. Weigh as follows according to the mass ratio: waste oil fatty acid 100g, sodium hydroxide 12g, surfactant OP‐107g, water 74g.

[0027] 2. Add 12g parts of sodium hydroxide to 32g water to prepare sodium hydroxide solution.

[0028] 3. Add the sodium hydroxide solution to 100 g of waste oil fatty acid, heat to 90° C., and stir for 20 minutes to saponify the fatty acid and the sodium hydroxide solution to obtain a mixture of fatty acid soap and incompletely reacted fatty acid.

[0029] 4. Add 7g of surfactant OP‐10 to 42g of water, heat to 70°C and disperse evenly.

[0030] 5. Add the uniformly dispersed surfactant OP-10 solution to the mixture of fatty acid soap and incompletely reacted fatty acid, stir at 90°C for 20 minutes, and obtain the reverse flotation collector 1 after the emulsification is complete.

Embodiment 2

[0032] A kind of waste oil collophosphane reverse flotation collector preparation method steps are as follows:

[0033] 1. Weigh as follows according to the mass ratio: waste oil fatty acid 100g, sodium hydroxide 16g, surfactant OP‐1010g, water 74g.

[0034] 2. Add 16g parts of sodium hydroxide to 32g water to prepare sodium hydroxide solution.

[0035] 3. Add the sodium hydroxide solution to 100 g of waste oil fatty acid, heat to 90° C., and stir for 20 minutes to saponify the fatty acid and the sodium hydroxide solution to obtain a mixture of fatty acid soap and incompletely reacted fatty acid.

[0036] 4. Add 10g of surfactant OP-10 into 42g of water, heat to 70°C and disperse evenly.

[0037] 5. Add the uniformly dispersed surfactant OP-10 solution to the mixture of fatty acid soap and incompletely reacted fatty acid, stir at 90°C for 20 minutes, and obtain reverse flotation collector 2 after the emulsification is complete.

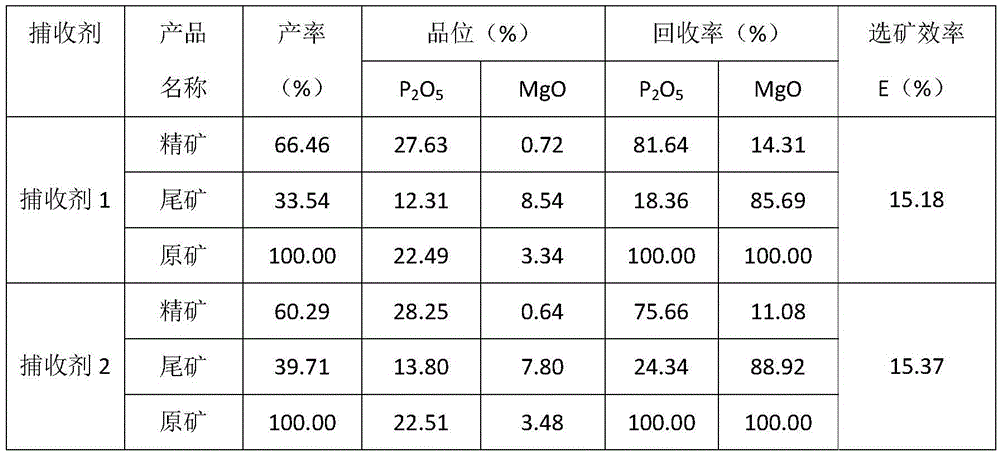

[0038] The reverse flotation collector 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com