Technique of mineral carbonation CO2 fixing joint produced carbonate products

A mineral carbonation, carbonate technology, applied in the preparation of carbonate/acid carbonate, chemical instruments and methods, dispersion particle separation, etc., can solve difficult large-scale industrial applications, acid medium regeneration difficulties, High economic cost and other issues, to achieve the effect of improving calcium conversion rate, good industrial application prospects, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

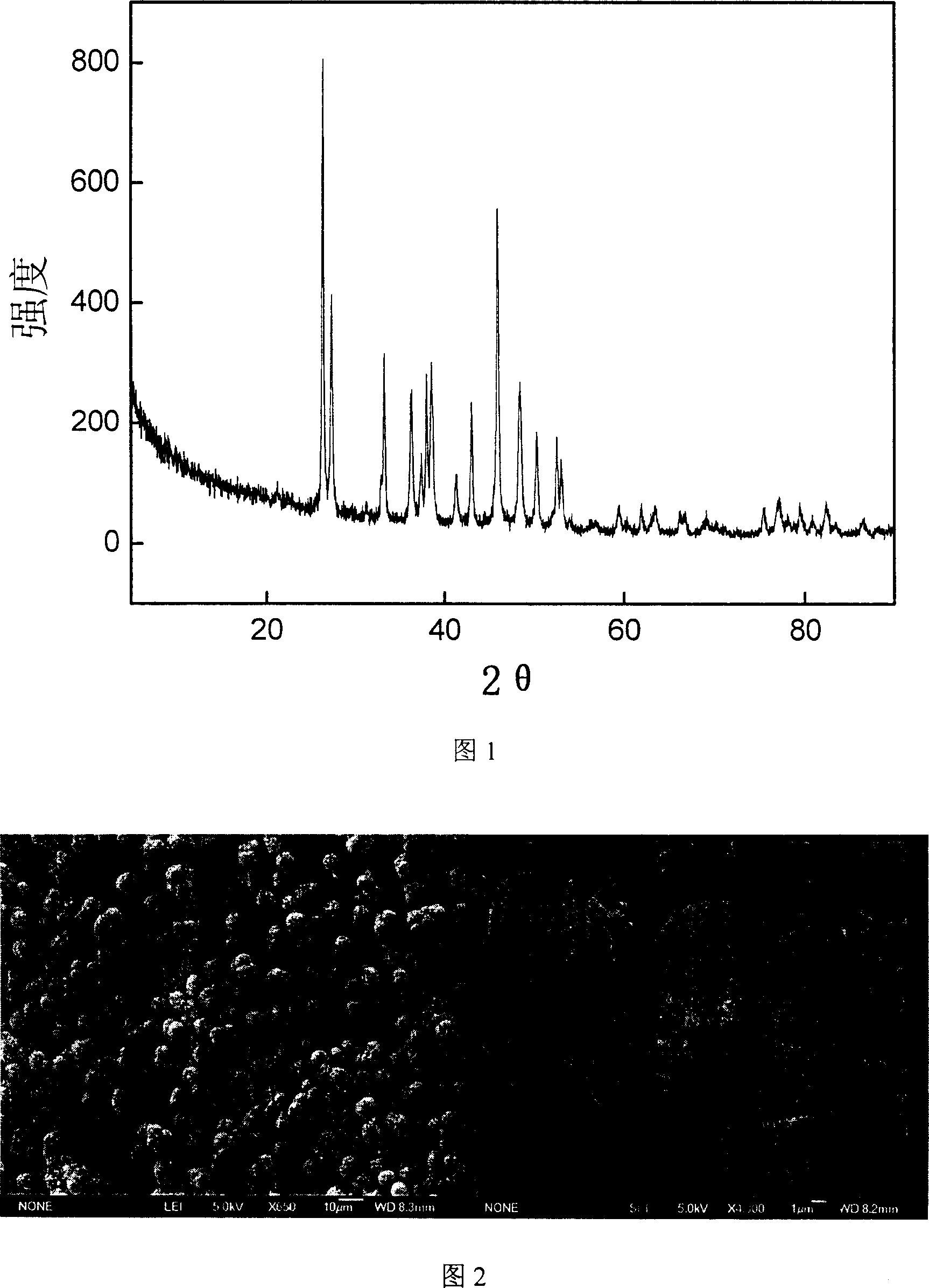

Embodiment 1

[0046] The calcium-containing solid waste in this embodiment is selected from iron and steel slag, and the main components in the iron and steel slag are: ~ 45% CaO, ~ 10% MgO, ~ 20% SiO 2 , ~20% FeO, and ~5% other impurities, the specific process is as follows:

[0047] 1) The steel slag is mechanically crushed and sieved to a particle size of 50 meshes to obtain steel slag particles;

[0048] 2) Get 40 grams of steel slag particles obtained in step 1), put them into a 250ml three-hole flask, then add 160ml of deionized water, put the above-mentioned three-hole flask into a magnetically stirred 60°C water bath, and place a straight Finally, slowly add 40ml of glacial acetic acid into the above-mentioned three-hole flask as the leaching medium to start the leaching reaction. The reaction is maintained for 60 minutes. After stopping the water bath, filter to obtain the calcium ion leaching solution. After measurement, the pH of the calcium ion leaching solution is obtained. =3...

Embodiment 2

[0060] The calcium-containing solid waste in this embodiment is selected from iron and steel slag, and the main components in the iron and steel slag are: ~45% CaO, ~10% MgO, ~20% SiO2, ~20% FeO, and ~5% other impurities, specifically The process is as follows:

[0061] 1) The steel slag is mechanically crushed and sieved to a particle size of 100 mesh to obtain steel slag particles;

[0062] 2) Get 40 grams of steel slag particles obtained in step 1), put them into a 250ml three-hole flask, then add 160ml of deionized water, put the above-mentioned three-hole flask into a magnetically stirred 80°C water bath, and place a straight Finally, slowly add 20ml of analytically pure lactic acid into the above-mentioned three-hole flask as the leaching medium to start the leaching reaction. The reaction is maintained for 120 minutes. After stopping the water bath, filter to obtain the calcium ion leaching solution. After measurement, the concentration of the calcium ion leaching solut...

Embodiment 3

[0072] Calcium-containing solid waste in this embodiment is selected from calcium carbide slag, the content of main components in the calcium carbide slag is: ~65% CaO, and ~35% other impurities. The specific process is as follows:

[0073] 1) Carbide slag is mechanically crushed and sieved to a particle size of 150 mesh to obtain carbide slag particles;

[0074] 2) Take 40 grams of calcium carbide slag particles obtained in step 1), put them into a 250ml three-hole flask, then add 160ml of deionized water, put the above-mentioned three-hole flask into a magnetically stirred 80°C water bath, and place a straight Finally, slowly add 80ml analytically pure propionic acid into the above-mentioned three-hole flask as a leaching medium, start the leaching reaction, keep the reaction for 30 minutes, stop the water bath and filter to obtain the calcium ion leaching solution. After measurement, the calcium ion leaching solution is obtained. PH=3-5;

[0075] 3) Place the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com