Beneficiation method capable of reducing leaching acid consumption of samirestie concentrate

A niobium-titanium-uranium ore dressing method technology, applied in chemical instruments and methods, flotation, magnetic separation, etc., can solve the problem of high acid consumption, achieve high grade, high recovery rate, and reduce the amount of acid-consuming minerals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The main uranium-containing minerals in a heavy separation concentrate in Shaanxi are niobium-titanium-uranite, and the gangue minerals mainly include microplagioclase, calcite, magnetite, pyrite, quartz, neonite, albite, and iron dolomite , sphene, biotite, allanite, epidote, hornblende, pyroxene, etc., the grade of uranium is 0.077%.

[0047] (1) Grind the gravity concentrate to -0.074mm, accounting for 50%, adjust the pulp concentration to 25%, put it into the flotation cell, add 200g / t of sulfide ore collector butyl xanthate, stir for 5min, add Foaming agent No. 2 oil 3g / t, stirring for 3min, inflating sulfide flotation to obtain flotation sulfide concentrate and flotation tailings.

[0048] (2) The flotation tailings are magnetically separated by a weak magnetic separator with a magnetic field strength of 1500 gauss to remove magnetite to obtain magnetite concentrate and magnetic separation tailings.

[0049] (3) Add inhibitor water glass 400g / t, carboxymethyl cel...

Embodiment 2

[0052] The main uranium-containing minerals in a heavy separation concentrate in Shaanxi are niobium-titanium-uranite, and the gangue minerals mainly include microplagioclase, calcite, magnetite, pyrite, quartz, neonite, albite, and iron dolomite , sphene, biotite, allanite, epidote, hornblende, pyroxene, etc., the grade of uranium is 0.077%.

[0053] (1) Grind the gravity concentrate to -0.074mm, accounting for 70%, adjust the pulp concentration to 30%, put it into the flotation cell, add 300g / t of sulfide ore collector butyl xanthate, stir for 5min, add Foaming agent No. 2 oil 3g / t, stirring for 3min, inflating sulfide flotation to obtain flotation sulfide concentrate and flotation tailings.

[0054] (2) The flotation tailings are first roughed with a weak magnetic separator with a magnetic field strength of 1200 Gauss to obtain roughed concentrate and roughed tailings. The roughened tailings are swept with a weak magnetic separator with a magnetic field strength of 1400 Gau...

Embodiment 3

[0058] The main uranium-containing minerals in a heavy separation concentrate in Shaanxi are niobium-titanium-uranite, and the gangue minerals mainly include microplagioclase, calcite, magnetite, pyrite, quartz, neonite, albite, and iron dolomite , sphene, biotite, allanite, epidote, hornblende, pyroxene, etc., the grade of uranium is 0.077%.

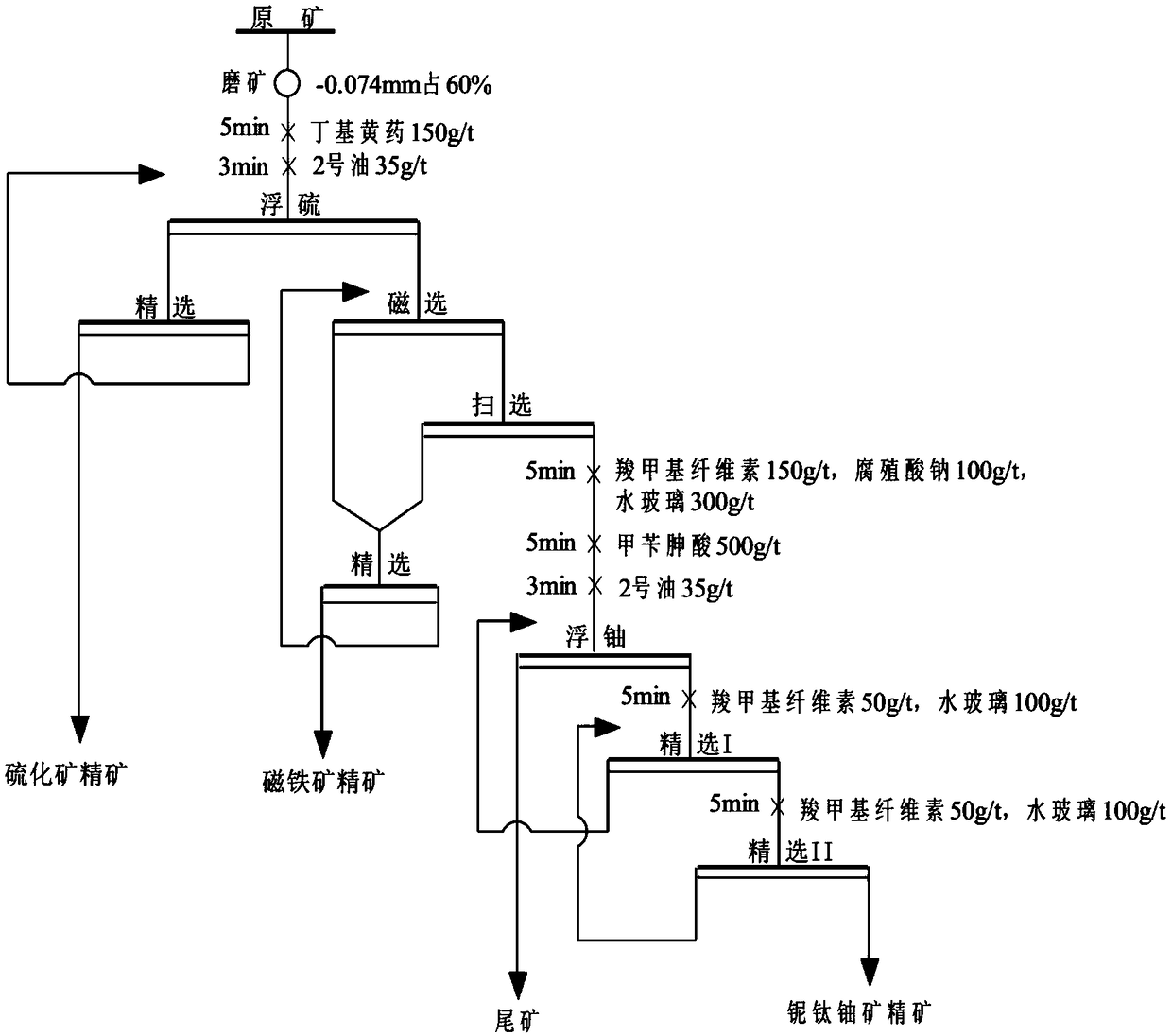

[0059] The closed-circuit flotation process is adopted, and the test process is shown in figure 1 .

[0060] (1) Grind the gravity concentrate to -0.074mm, accounting for 80%, adjust the pulp concentration to 30% and put it into the flotation tank, add 150g / t of sulfide ore collector butyl xanthate, stir for 5min, add Foaming agent No. 2 oil 3g / t, stirring for 3min, aerated sulfide flotation to obtain roughing sulfide concentrate and roughing tailings, roughing sulfide concentrate is selected once, and the selected concentrate is sulfide concentrate ore, and the selected tailings return to the roughing process.

[0061] (2) The rough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com