Production of potassium and magnesium fertilizer

A production method and technology of potassium and magnesium fertilizers, applied in the direction of magnesium fertilizers, potash fertilizers, inorganic fertilizers, etc., can solve the problems of losing market competitive advantages and high costs of potassium and magnesium fertilizers, and achieve the goals of enhanced resistance to diseases and insect pests, improved rice grades, and foreign exchange savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

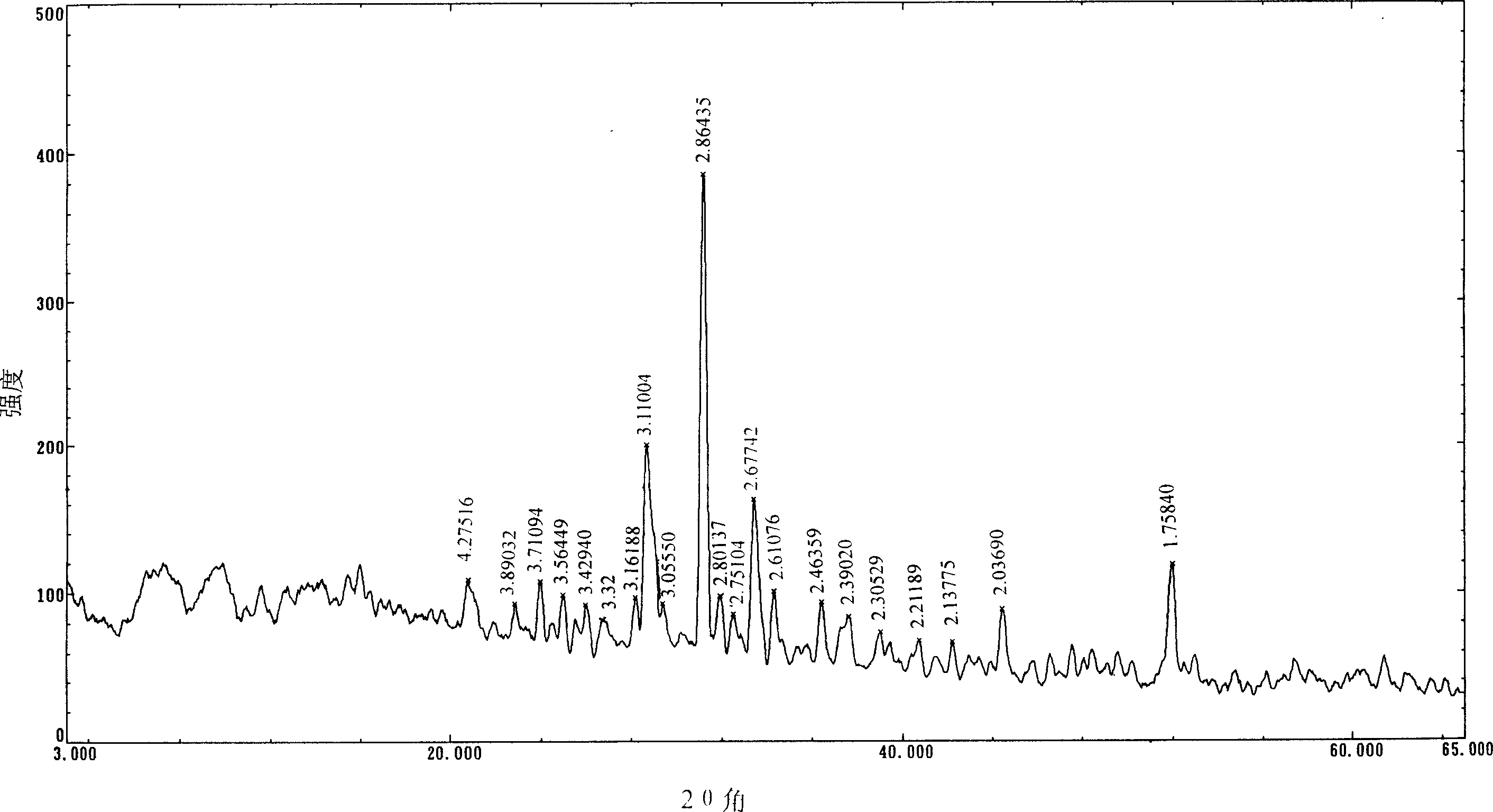

Image

Examples

Embodiment 1

[0013] Embodiment 1, get potassium feldspar, limestone, dolomite purification treatment of potassium oxide mass percentage 15% and be crushed to particle diameter 10-20mm (millimeter) respectively, white coal is crushed to particle diameter 1-2mm, press 1 part of potassium ore (parts by mass, the same below), 0.84 parts of limestone, 0.40 parts of dolomite, 0.22 parts of white coal powder, 0.085 parts of conversion agent (calcium chloride+sodium hydroxide) (calcium chloride: sodium hydroxide=1: 0.2) ingredients Mix evenly, grind into a ball mill to a particle size of 0.074mm, and then make balls with a diameter of about 10-15mm. Calcined in cement shaft kiln, sintered at 1000-1300°C for about 35 minutes, cooled and discharged out of the kiln. Then it is ground to a fineness of more than 90% and passed through a 120-mesh sieve to obtain a powdery product. After granulation, it is a granular product.

Embodiment 2

[0014] Embodiment 2, get the potassium ore (potassium feldspar and illite), limestone, dolomite purification treatment of 13% potassium oxide mass percentage and crush respectively to particle diameter 10-15mm (millimeter), and anthracite is crushed to particle diameter 1-1.5mm , according to 1 part of potassium ore (potassium feldspar: illite=1:0.45, parts by mass, the same below), 0.77 part of limestone, 0.43 part of dolomite, 0.21 part of anthracite, conversion agent (calcium chloride+ammonium sulfate+hydroxide Calcium) 0.09 part (calcium chloride: ammonium sulfate: calcium hydroxide=1: 0.6: 0.2) ingredients are mixed evenly, put into a ball mill and grind to a particle size of 0.074mm, and make balls, the ball diameter is about 8-12mm. Put it into cement rotary kiln for calcination, and sinter at 1000-1250°C for 30-35 minutes, and the balls will become gray-black lumps with a diameter of 30-50mm. After being cooled and discharged from the kiln, it is ground to a fineness o...

Embodiment 3

[0015] Embodiment 3, get the potash ore (potassium feldspar+illite+glaconite), limestone, dolomite purification treatment of potassium oxide mass percentage 12% and be crushed to particle diameter 5-15mm (millimeter) respectively, and white coal is broken to Particle size 1-2mm, according to 1 part of potassium ore (potassium feldspar: illite: glauconite = 1:0.40:0.15, parts by mass, the same below), 0.71 part of limestone, 0.48 part of dolomite, 0.23 part of white coal powder , conversion agent (magnesium chloride+calcium sulfate+calcium hydroxide) 0.1 part (magnesium chloride: calcium sulfate: calcium hydroxide=0.8: 1: 0.2) batching mixes evenly, enters ball mill and grinds to particle diameter 0.074mm, then ball making, ball diameter About 5-10mm. Put it into the cement vertical kiln for calcination, and sinter at 1000-1230°C for about 30 minutes, so that the balls are fired into gray-black cooked blocks with a diameter of 30-50mm. After cooling out of the kiln, grind to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com