Flotation and acid leaching process for complex low-grade copper oxide ore

A copper oxide ore, low-grade technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve problems such as harsh conditions, complex process, and index deterioration, achieve small metal loss, overcome process complexity, reduce The effect of acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

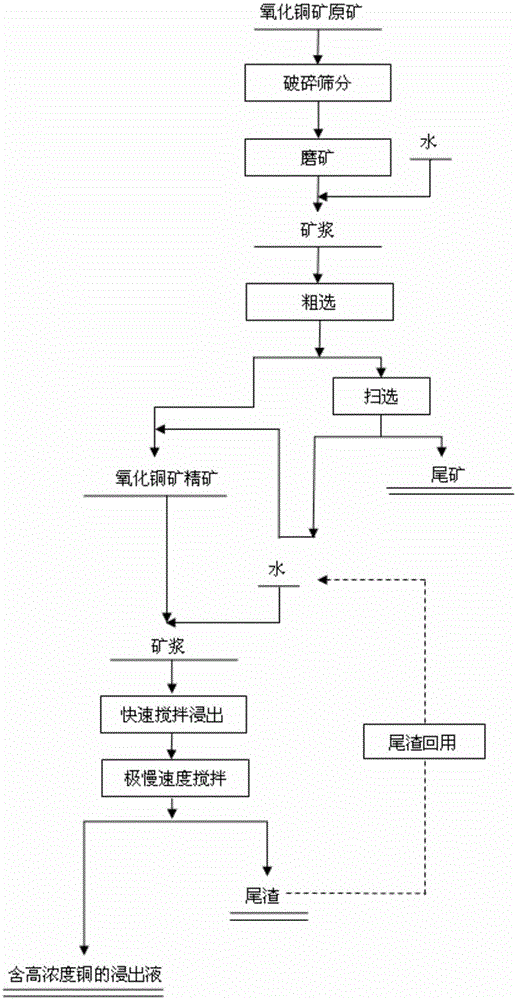

Image

Examples

Embodiment 1

[0025]Congo complex low-grade copper oxide ore is used, which contains Cu1.2960%, Si25.5600%, Ca0.4160%, Mg13.1200%, Al7.5100%, Fe3.0030%. The results of XRD analysis showed that the main gangue minerals contained in the copper ore were quartz, chlorite, dolomite and talc, and mica and gibbsite were also contained. No single minerals containing copper were detected by XRD. The copper oxide ore raw ore is crushed and screened to a feeding particle size of 3 mm, and the crushed copper oxide ore raw ore particles are then ground with a ball mill to -200 mesh, accounting for 80%. At this time, the copper-containing mineral monomer is fully dissociated; The good pulp is configured into a pulp with a concentration of 30% for flotation operation, adding 7000g / t of sodium sulfide nonahydrate, 1000g / t of amyl xanthate, and 30g / t of 2# oil. After rough selection, carry out a sweep selection, add 2000g / t of sodium sulfide nonahydrate, 300g / t of amyl xanthate, and 14g / t of 2# oil. The mi...

Embodiment 2

[0027] Mabende complex low-grade copper oxide raw ore is used, which contains Cu1.0856%, Si26.2309%, Ca1.8421%, Mg12.4872%, Al5.3285%, Fe2.8046%. XRD analysis results show that the main gangue minerals contained in the copper ore are quartz, chlorite, dolomite, calcite, talc, mica and gibbsite. The copper oxide ore raw ore is crushed and screened to a feeding particle size of 3 mm, and the crushed copper oxide ore raw ore particles are then ground with a ball mill to -200 mesh, accounting for 80%. At this time, the copper-containing mineral monomer is fully dissociated; The good pulp is configured into a pulp with a concentration of 30% for flotation operation, adding 7000g / t of sodium sulfide nonahydrate, 1500g / t of amyl xanthate, 30g / t of 2# oil, and sulfidation flotation roughing after adjusting. After rough selection, carry out 1 sweep selection, add 1800g / t of sodium sulfide nonahydrate, 350g / t of amyl xanthate, and 12g / t of 2# oil. The middle ore is combined with the ro...

Embodiment 3

[0029] Congo complex low-grade copper oxide ore is used, which contains Cu1.4136%, Si23.0805%, Ca0.5619%, Mg12.6310%, Al7.1889%, Fe3.1521%. XRD analysis results show that the main gangue minerals contained in the copper ore are quartz, calcite, chlorite, dolomite, talc, mica and gibbsite. The copper oxide ore raw ore is crushed and screened to a feeding particle size of 3 mm, and the crushed copper oxide ore raw ore particles are then ground with a ball mill to -200 mesh, accounting for 85%. At this time, the copper-containing mineral monomer is fully dissociated; The good pulp is configured into pulp with a concentration of 40% for flotation operation, adding 8000g / t of sodium sulfide nonahydrate, 1200g / t of amyl xanthate, and 25g / t of 2# oil. After selection, carry out 1 sweep selection, add 1500g / t of sodium sulfide nonahydrate, 400g / t of amyl xanthate, and 9g / t of 2# oil. The middle ore is combined with the rough concentrate to obtain copper oxide concentrate; the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com