Process for direct flotation and double reverse flotation of low-grade collophanite

A collophosite, low-grade technology, applied in the field of direct double reverse flotation process of low-grade collophosphine, can solve the problems of content reduction, difficult to obtain phosphorus concentrate, etc., and achieve the effect of improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

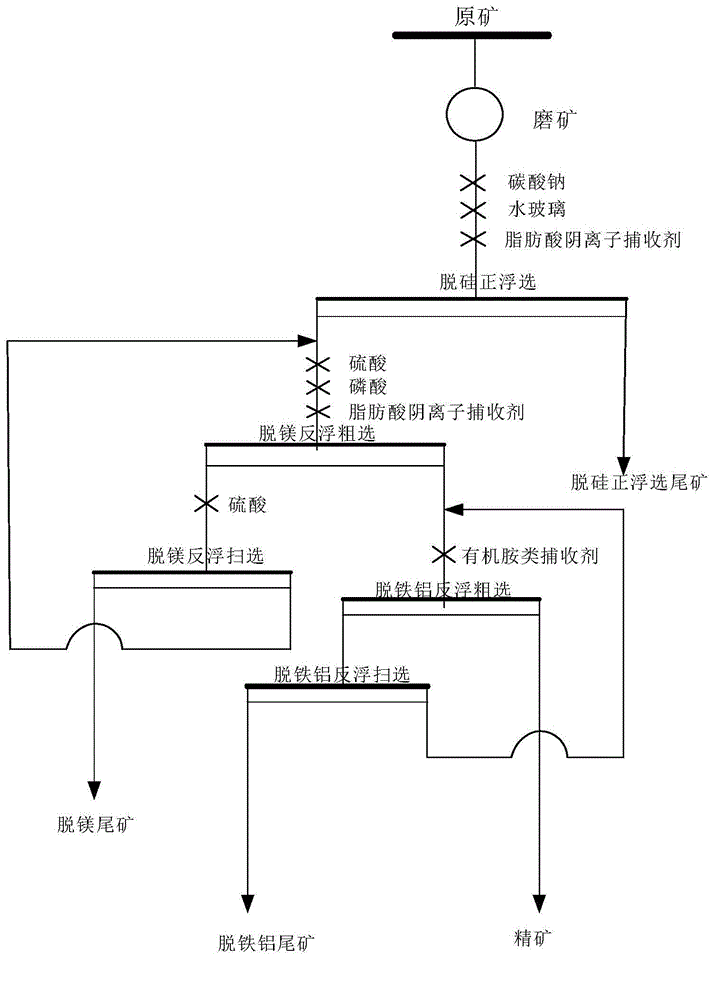

Image

Examples

Embodiment 1

[0018] A kind of direct double reverse flotation process of low-grade collophosphine, its steps are as follows:

[0019] 1) Take high-sesquioxide silicon-calcium low-grade colloidal phosphate rock, wherein P 2 o 5 The grade is 14.45%, the mass content of MgO is 5.0%, SiO 2 The mass content is 30%, Fe 2 o 3 with Al 2 o 3 The sum of the mass is 5.26%. After crushing and grinding, the mineral monomers are dissociated through crushing and grinding, and the slurry is adjusted to a mass concentration of 20%. Then it flows into the mixing tank, and the amount of 3.0 kg / t raw ore sodium carbonate, 6.0kg / t raw ore water glass, adjust the pH value of the pulp to 9, and then add 3.0kg / t anionic fatty acid soap collector TSM-46 to make slurry, and then enter In the positive flotation operation, aerated flotation is carried out, and phosphate ore, carbonate minerals and some iron-aluminosilicate minerals enter the positive flotation foam product; the positive flotation tailings are i...

Embodiment 2

[0023] A kind of direct double reverse flotation process of low-grade collophosphine, its steps are as follows:

[0024] 1) Take high-sesquioxide silicon-calcium low-grade colloidal phosphate rock, wherein P 2 o 5 The grade is 18.25%, the mass content of MgO is 2.5%, SiO 2 The mass content is 24.56%, Fe 2 o 3 with Al 2 o 3 The sum of the mass is 6.26%. After crushing and grinding, the mineral monomers are dissociated through crushing and grinding, and the slurry is adjusted to a mass concentration of 40%. Then it flows into the mixing tank, and the amount of 8.0 kg / t raw ore sodium carbonate, the dosage is 0.5kg / t raw ore water glass, adjust the pH value of the pulp to 11, and then add the dosage of 0.5kg / t anionic fatty acid soap collector TSM-46 to adjust the slurry. After entering the positive flotation operation for aerated flotation, phosphate ore, carbonate minerals and some iron-aluminosilicate minerals enter the positive flotation foam product; the tank is positi...

Embodiment 3

[0028] A kind of direct double reverse flotation process of low-grade collophosphine, its steps are as follows:

[0029] 1) High-sesquioxide silicon-calcium low-grade colloidal phosphate rock, of which P 2 o 5 The grade is about 23%, the mass content of MgO is 1.0%, SiO 2 The mass content is 12%, Fe 2 o 3 with Al 2 o 3The sum of the mass is 8.26%. After crushing and grinding, the mineral monomers are dissociated, and the slurry is adjusted to a mass concentration of 30%. Then it flows into the mixing tank, and the amount of 5.5 kg / t raw ore sodium carbonate, the dosage is 3.5kg / t raw ore water glass, adjust the pH value of the pulp to 10.25, and then add the dosage of 1.5kg / t anionic fatty acid soap collector TSM-46 to adjust the slurry. After entering the positive flotation operation for aerated flotation, phosphate ore, carbonate minerals and some iron-aluminosilicate minerals enter the positive flotation foam product; the tank is positive flotation tailings;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com