Direct and reverse flotation desliming process of collophanite

A collophosphate and flotation technology, applied in the field of beneficiation, can solve the problems of the influence of recovery rate and concentrate grade, the large content of fine mud in phosphate rock, and the increase in the consumption of flotation chemicals, so as to reduce the consumption of chemicals, The effect of reducing pollution, improving flotation recovery and concentrate grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

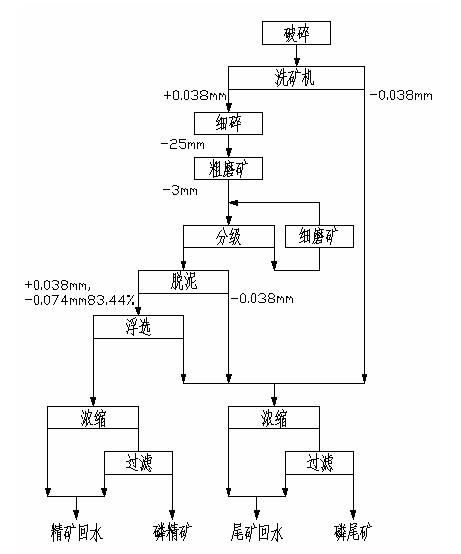

[0024] The collophosite desliming flotation process is carried out according to the following steps:

[0025] 1. After crushing and before grinding, the collophosite raw ore enters the ore washing machine for scrubbing, and the raw ore is divided into two parts: coarse-grained and fine-grained according to the particle size;

[0026] 1.1. The coarse-grained part (greater than 0.038 mm) enters the grinding and grading process after passing through the washing machine;

[0027] 1.2. The fine-grained part (less than 0.038 mm) is the fine mud removed after passing through the washing machine, which is the tailings produced by the washing machine;

[0028] 2. Part of the pulp in the coarse-grained grade enters the hydrocyclone for desliming after entering the grinding and classification before flotation;

[0029] 2.1. The sand settling part (greater than 0.038 mm; less than 0.074 mm, accounting for 83.44%) enters the positive and negative flotation process after passing through th...

Embodiment 2

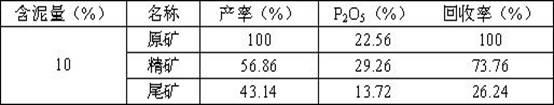

[0035] Using the collophosite desliming flotation process of the present invention, when the pH regulator Na in the prior art 2 CO 3 , Inhibitor Na 2 SiO 3 When the amount of collector and collector is constant, -400 mesh is muddy, and the flotation index is as follows:

[0036]

Embodiment 3

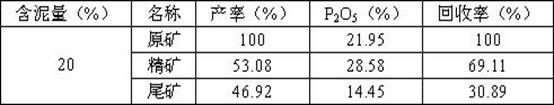

[0038] Using the collophosite desliming flotation process of the present invention, when the pH regulator Na in the prior art 2 CO 3 , Inhibitor Na 2 SiO 3 When the amount of collector and collector is constant, -400 mesh is muddy, and the flotation index is as follows:

[0039]

[0040] In the foregoing examples, along with the reduction of mud content in the collophosite raw ore, the concentrated ore yield increases, and the concentrated ore P 2 o 5 As the grade increases, the beneficiation recovery rate also increases.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com