Phosphate rock floating process

A phosphate rock and flotation technology, applied in flotation, solid separation and other directions, can solve the problems of large consumption of flotation reagent collectors, decreased reverse flotation efficiency, fine-grain inclusions, etc., and reduce the consumption of flotation reagents. , Improve the sorting efficiency and save the effect of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

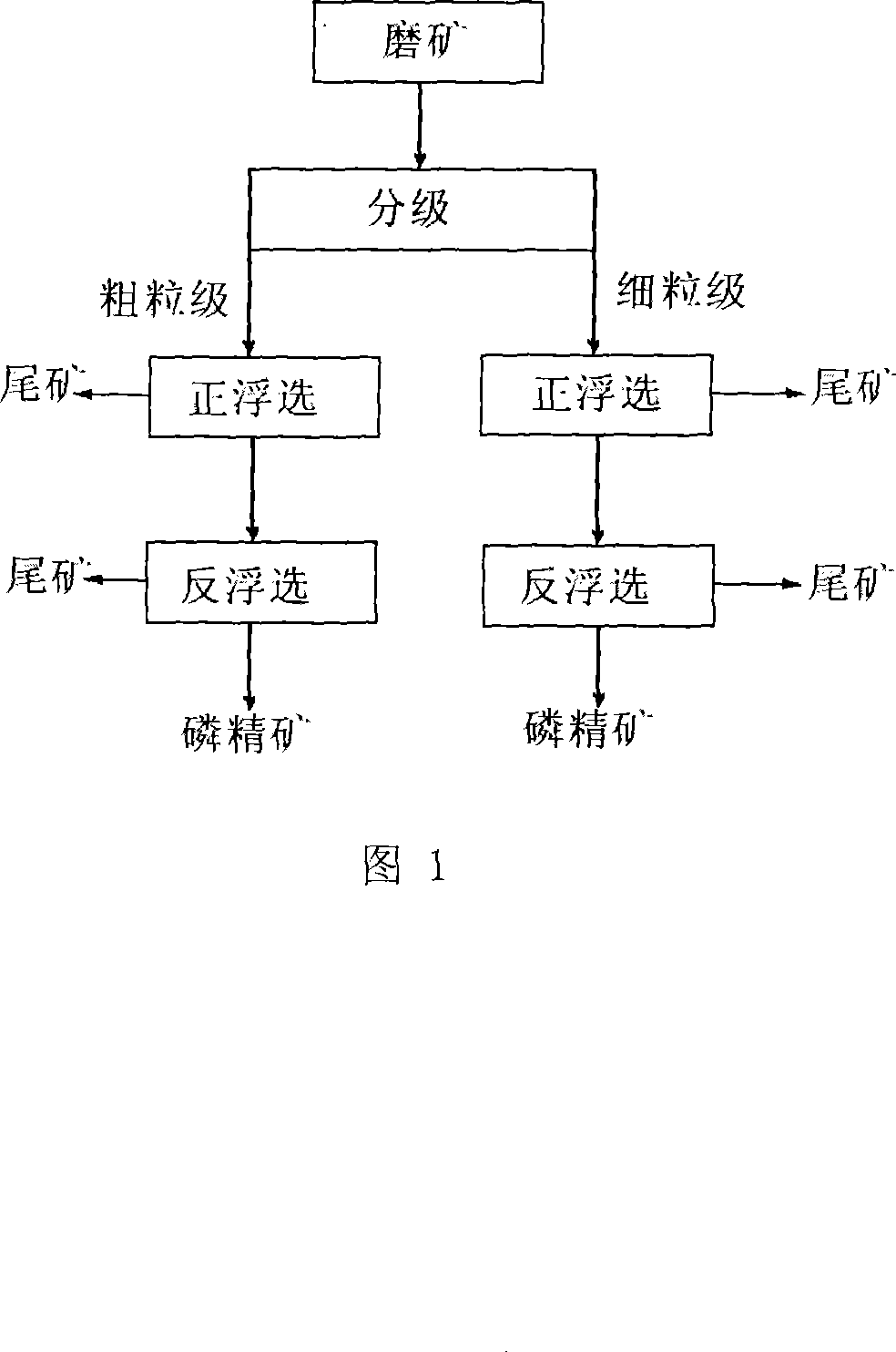

[0035] As shown in Figure 1, a kind of phosphate rock flotation process, it comprises the steps:

[0036] 1) After the raw phosphate ore is finely ground, the raw ore pulp enters a classification device (such as a hydrocyclone) to divide the raw ore pulp into two parts: coarse-grained and fine-grained according to the particle size; the fine-grained part The particle size of the raw ore pulp is less than or equal to 38 microns, and the particle size of the coarse-grained part of the raw ore pulp is greater than 38 microns;

[0037] 2a) Part of the coarse-grained raw ore pulp is concentrated to a pulp with a concentration of 55%, and then flows into the stirring tank, and then respectively adds a positive flotation regulator and a positive flotation collector to the pulp to adjust the slurry. The positive flotation regulator, positive flotation The addition amount of flotation collectors is 2kg / t coarse-grained part of raw ore pulp and 1.36kg / t coarse-grained part of raw ore pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com