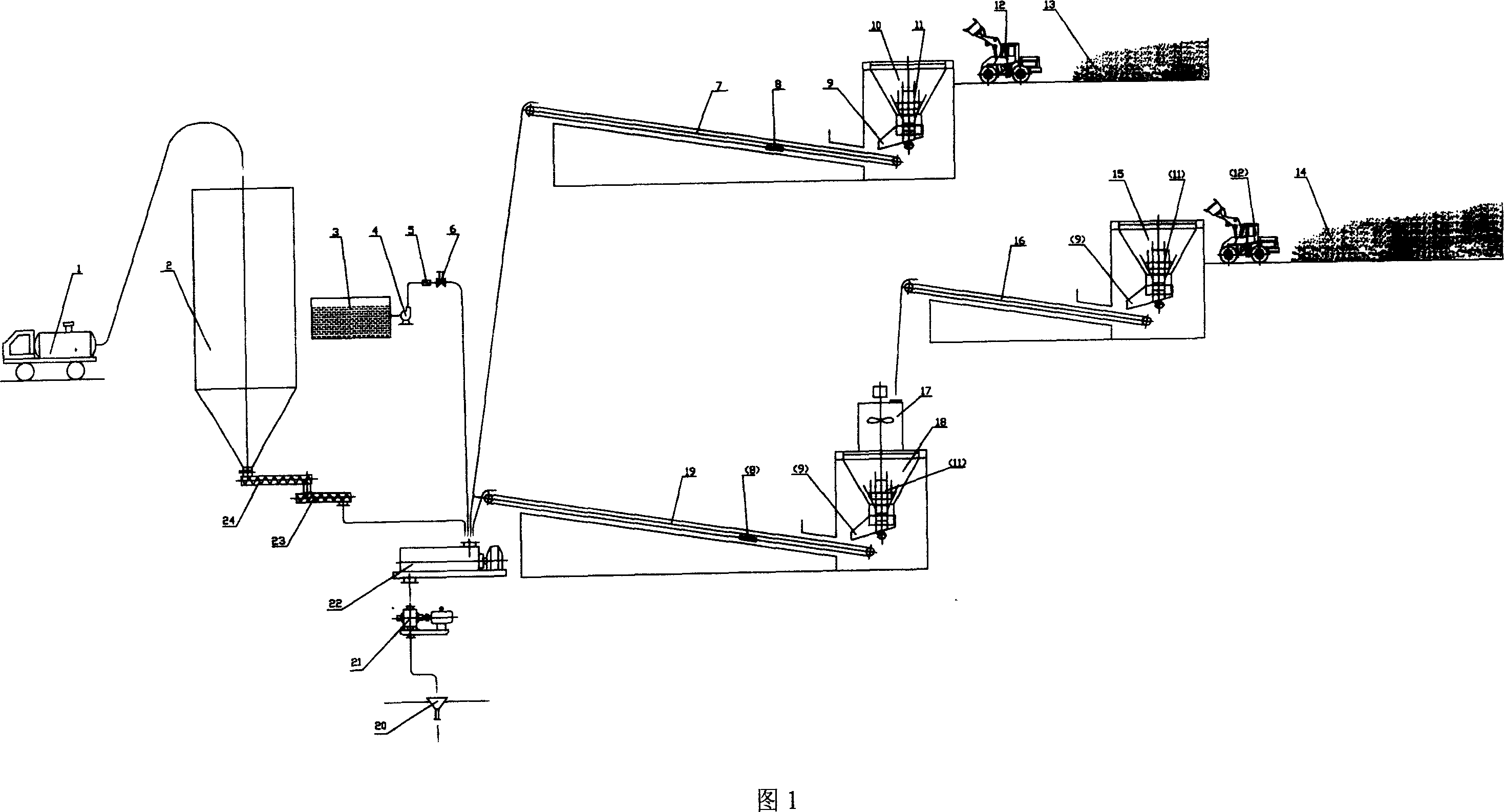

Phosphogypsum cementing and post-filling mining method and pulping technology thereof

A filling mining method and cemented filling technology, which is applied to filling materials, mining equipment, earth square drilling and mining, etc., can solve the problems of associated ore body loss, etc., and achieve the effects of protecting the environment, less dehydration in the stope, and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

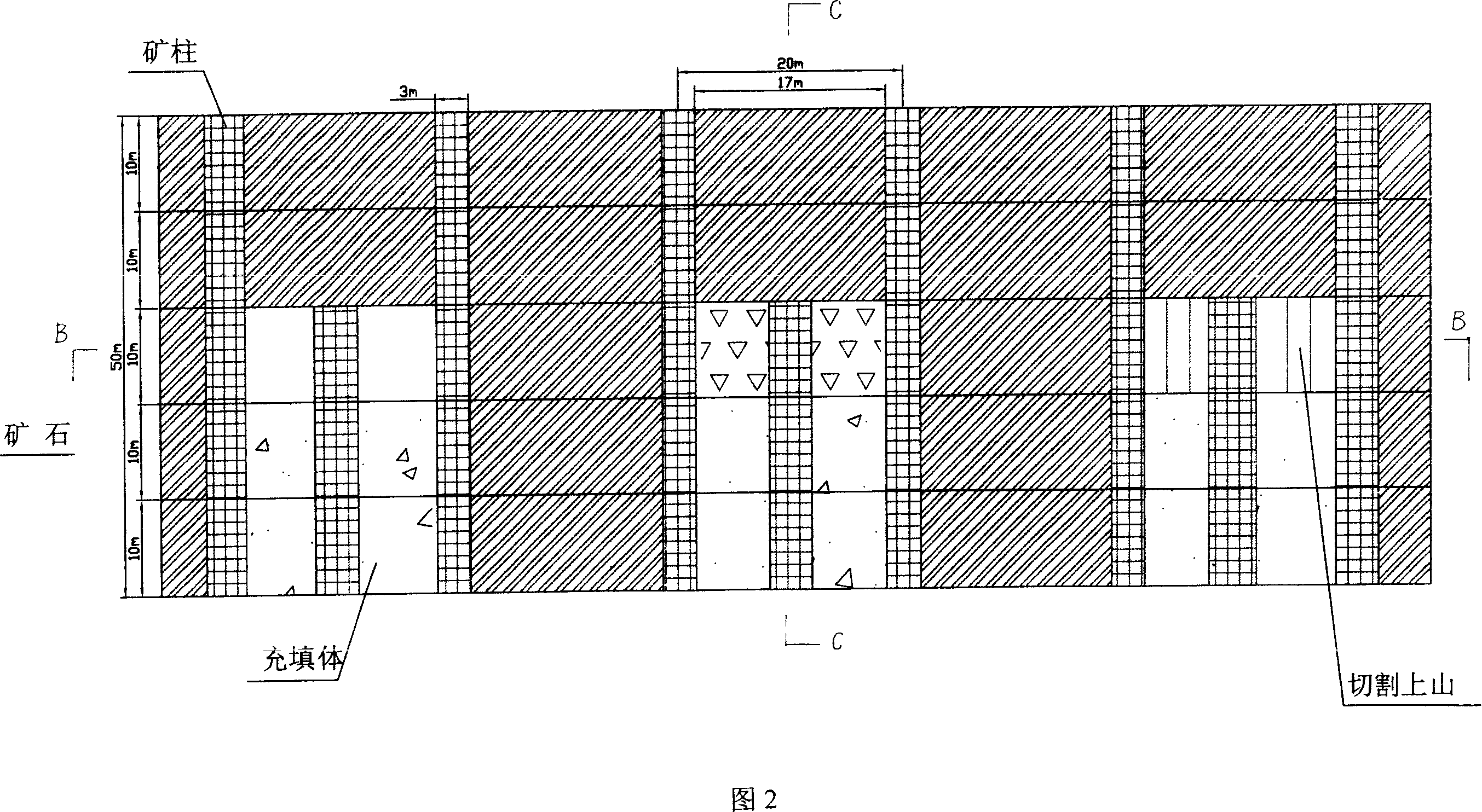

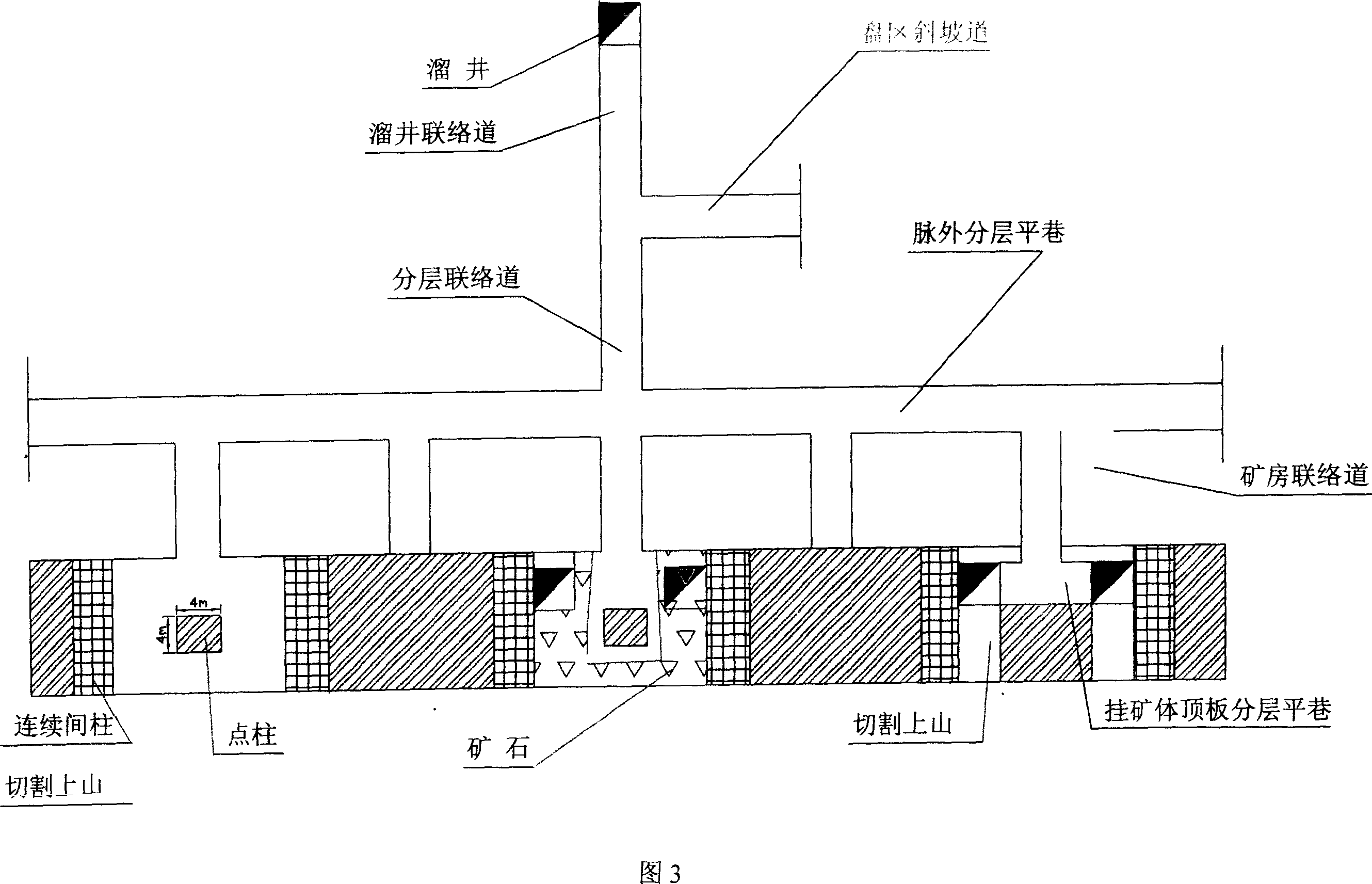

[0017] Example The Shaba Mine for Kailin (Group) is a subordinate mine of Guizhou Kailin Group Corporation Mining Corporation, and its retained geological reserves are more than 50 million tons. The original mining method of the mine was the empty field method. The height of the middle section is 50 meters, the height of the sections is 10 meters, the length of the stope is 10-12 meters, and there is a column of 4 meters between the stope and the stope.

[0018] Using the phosphogypsum cemented subsequent filling mining method of the present invention, the ore block with a strike length of 1100m is divided into two panels along the strike, each panel is divided into 5 layers, and each layer has a vertical height of 10m. The panel ramp is arranged in the middle of each ore block. When the panel ramp is constructed to the elevation of each layer, it is arranged in the orebody roof 15m away from the orebody roof line and the vein layered roadway, then Enter each ore house according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com