Passivator for controlling pollutions of heavy metals copper, lead and cadmium on soil and applications thereof

A heavy metal and passivating agent technology, applied in the restoration, application, soil conditioning materials and other directions of polluted soil, can solve the problems of hyperaccumulation of plant biomass limitation, unsuitable for large-scale operation, cumbersome preparation process, etc., to achieve environmental friendliness , the effect of short cycle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation of embodiment 1 passivating agent

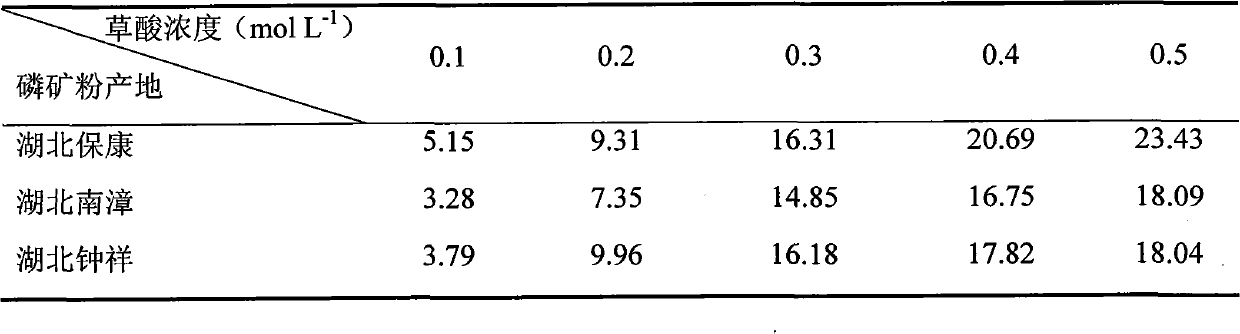

[0012] The three phosphate rock powders tested were produced in Baokang, Nanzhang and Zhongxiang, Hubei respectively, and their P 2 o 5 The content is 26.1%, 24.2% and 23.2% in turn. Weigh about 0.25g of phosphate rock powder passed through a 100-mesh sieve (particle size: 0.15mm) into a 50mL centrifuge tube, add 5mL of -1 The oxalic acid is cultivated and activated in a thermostat at 40±0.5°C for 6 days, and dried at 50°C to obtain activated phosphate rock powder. The following are the three phosphate rock powders activated by oxalic acid P 2 o 5 % detection data (Table 1).

[0013] Table 1 The available phosphorus content (P 2 o 5 %)

[0014]

Embodiment 2

[0015] The preparation of embodiment 2 passivating agent

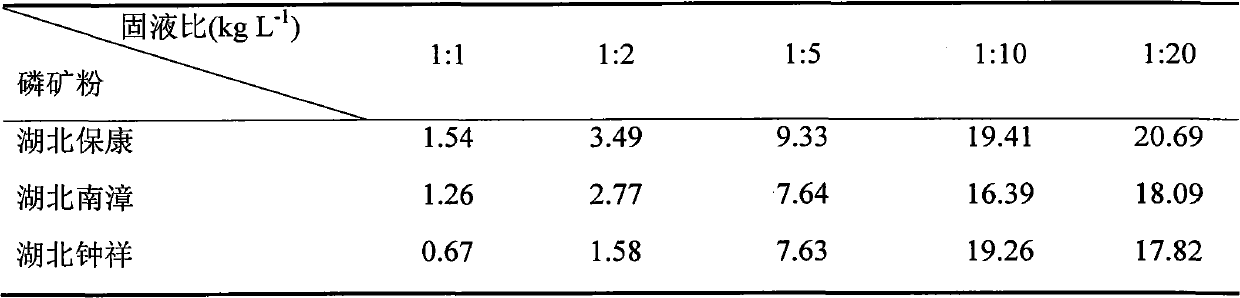

[0016] Weigh 5, 2.5, 1, 0.5, and 0.25 g of phosphate rock powder passed through a 100-mesh sieve into a 50 mL centrifuge tube, and add 5 mL of it to a concentration of 0.5 mol L -1 The oxalic acid is cultivated and activated in a thermostat at (40±0.5)°C for 6 days, and dried at 50°C to obtain activated phosphate rock powder. The following are the three kinds of phosphate rock powder activated by oxalic acid, P 2 o 5 % detection data (see Table 2).

[0017] Table 2 The available phosphorus content (P 2 o 5 %)

[0018]

Embodiment 3

[0019] The preparation of embodiment 3 passivating agent

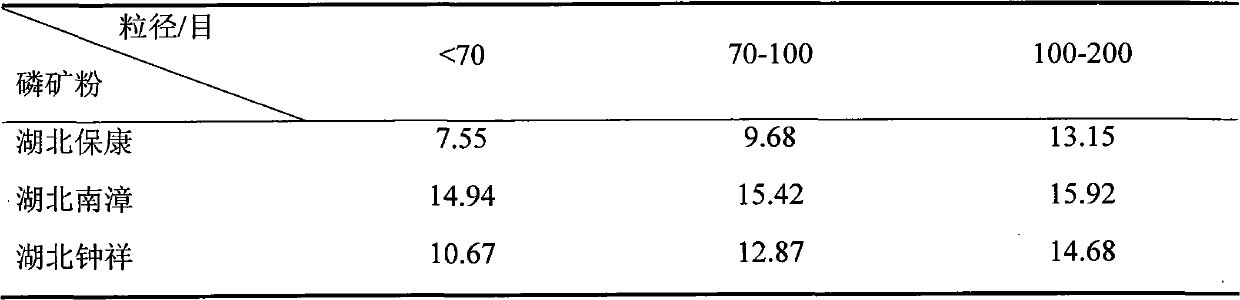

[0020] Weigh 0.25g of phosphate rock powder with different particle sizes into a 50mL centrifuge tube, add 5mL of -1 The oxalic acid is cultivated and activated in an incubator at 40±0.5°C for 6 days, and dried at 50°C to obtain activated phosphate rock powder. The following are three kinds of phosphate rock powder activated by oxalic acid, P 2 o 5 % detection data (Table 3).

[0021] Table 3 The available phosphorus content (P 2 o 5 %)

[0022]

[0023] Embodiment 4 application embodiment

[0024] According to the results of Examples 1, 2, and 3, the optimum method for determining the preparation of passivator is as follows: mix the phosphate rock of 100 mesh sieves with 0.5mol L -1 The oxalic acid is mixed at a solid-to-liquid ratio of 1:10, activated at 28°C for 6 days, and dried at 50°C for 20-24h. The passivators used in the following application examples are all prepared by this method. P 2 o 5 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com