Method for continuous production of n-butyl chloride

A technology of n-chlorinated butane and n-butanol, which is applied in the field of continuous production of n-chlorinated butane, can solve the problems of process loss, unit consumption of raw materials, high energy consumption, and inability to recycle, and achieve low loss of organic matter and high recovery small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

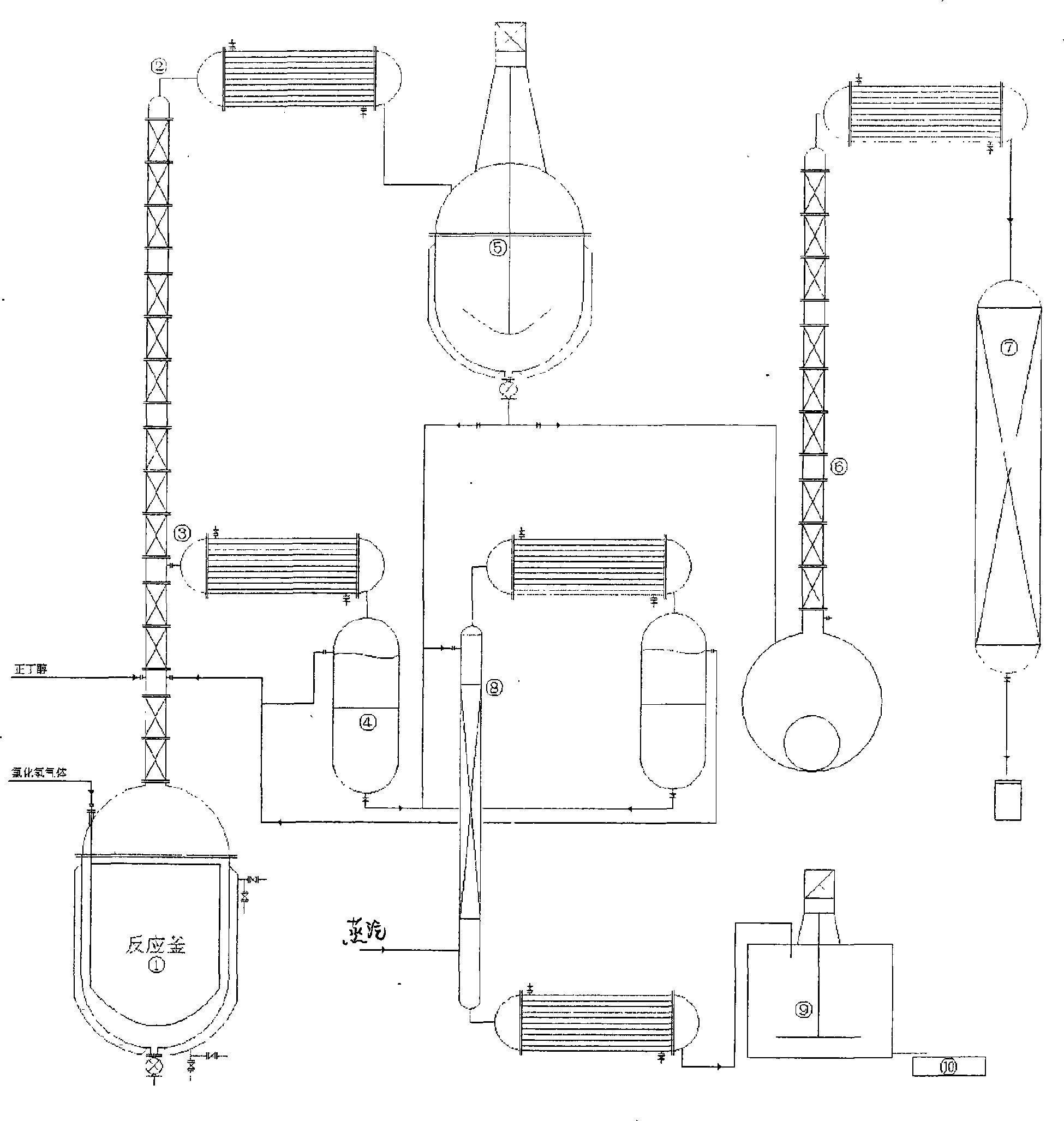

[0016] A method for continuous production of chlorobutane, the process is composed of a reactive distillation section, a n-butanol recovery section, and a washing and rectifying section:

[0017] (1) In the reaction distillation section, a distillation tower is directly installed at the outlet of the synthesis reaction kettle 1, hydrogen chloride gas is passed through the bottom of the synthesis reaction kettle through a gas distributor, and n-butanol is poured in from the bottom of the distillation tower, and hydrogen chloride and n-butanol are molar The ratio of 0.9-1:1 is continuously added to the synthesis reaction kettle, and the temperature of the distillation tower top in the reaction distillation section is controlled at 68±1°C. At the azeotropic temperature, the 2 azeotropes at the top of the distillation tower are cooled and enter the water washing rectification section, washed by the washing kettle 5 and rectified by the rectifying tower 6, then dried in the drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com